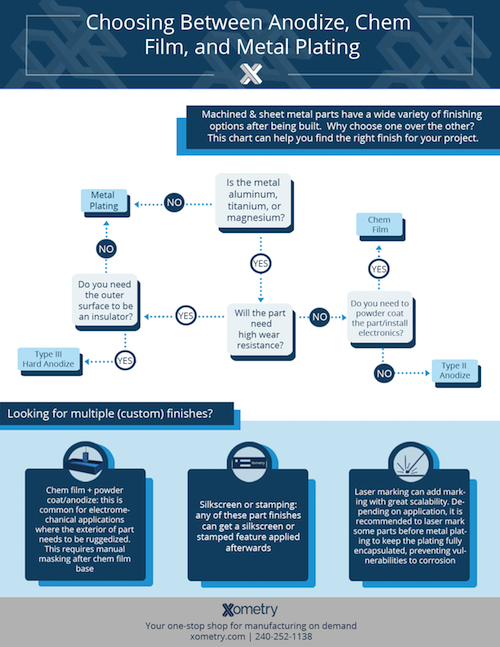

Infographic: Choosing Between Anodize, Chem Film, and Metal Plating

Will your CNC machined part be... made out of aluminum, titanium, or magnesium? An insulator or wear resistant? Follow this decision tree to help you choose the best finish for your project.

Need more information on finishes? Check out this video, "Choosing the Right Surface Finish for Your Metal Parts," starring Greg Paulsen, Dir. Application Engineering, and Tolu Akingbade, Supplier Quality Engineer.

They discuss how to choose the right surface finish for your metal parts. They take a close look at the pros, cons, and important considerations for the three most common finishes: anodizing, chem film, and metal plating.