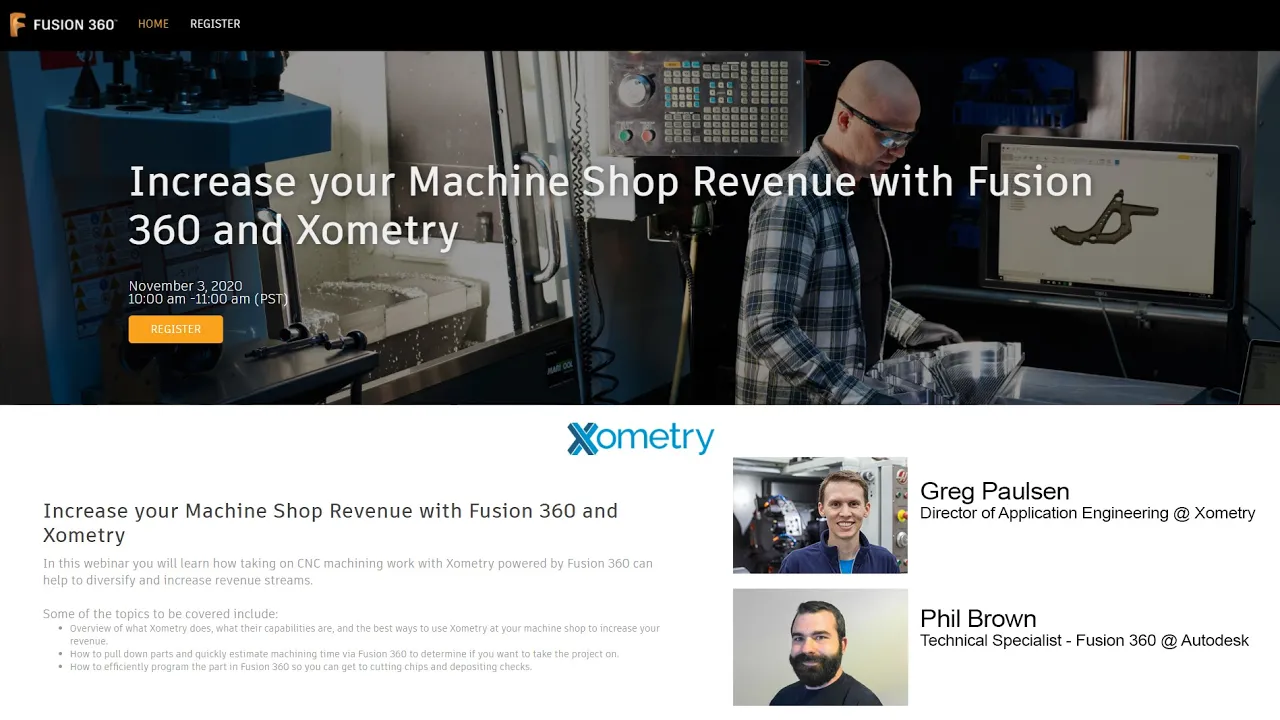

On-Demand Webinar: Increase your Machine Shop Revenue with Fusion 360 and Xometry

In this webinar you will learn how taking on CNC machining work with Xometry powered by Fusion 360 can help to diversify and increase your revenue streams.

In this webinar you will learn how taking on CNC machining work with Xometry powered by Fusion 360 can help to diversify and increase revenue streams.

Some of the topics to be covered include:

- Overview of what Xometry does, what their capabilities are, and the best ways to use Xometry at your machine shop to increase your revenue.

- How to pull down parts and quickly estimate machining time via Fusion 360 to determine if you want to take the project on.

- How to efficiently program the part in Fusion 360 so you can get to cutting chips and depositing checks.

Speaker Biographies

Phil Brown is a Technical Specialist for Fusion 360 at Autodesk. Phil is an expert in taking big blocks of material and turning them into smaller & more expensive blocks of material. He has been a professional machinist for the last 10+ years, with a background ranging from Aerospace and Automation parts to Tool Dies and Molds. Phil has been using Fusion 360 for programming parts for over 4 years and has been working at Autodesk for the last year.

Greg Paulsen,or more commonly known as Xometry Greg on Twitter, leads the Applications Engineering team at Xometry, working directly with customers on special case projects that require attention on material selection, design-for-manufacturing, or technical engineering resources. With over a decade of experience, he has worked on thousands of manufacturing projects using machining, injection molding, and a variety of additive manufacturing (3D printing) methods. Greg also plays a vital role in vetting new technologies and materials to add to Xometry's manufacturing portfolio both for the instant quoting engine and their expanding marketplace.