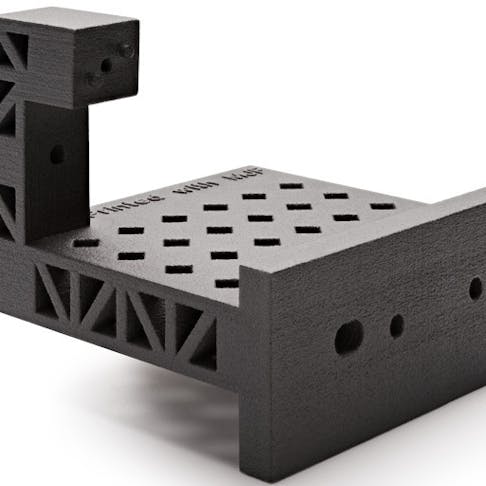

Product Update: New Materials for HP Multi Jet Fusion (MJF)

Now you can order MJF parts in two new materials: Nylon 11 and TPU 95A.

Xometry’s HP Multi Jet Fusion service is a more cost-effective way than ever to buy 3D printed parts. Now, you can order MJF parts in two new materials: Nylon 11 and TPU 95A.

New Materials for MJF

Xometry’s HP Multi Jet Fusion service is now adding two new materials: Nylon 11 (PA 11) and TPU 95A (Estane M95A). These materials will join Nylon 12 (PA 12) and glass-filled Nylon 12 (PA 12 GB) to round out HP Multi Jet Fusion’s current material offerings.

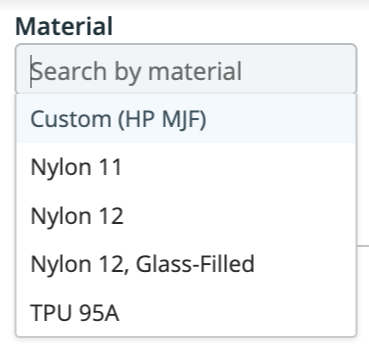

As seen below, the new materials are available in the drop-down menu in Xometry’s Instant Quoting Engine℠

Nylon 11 has optimal mechanical properties, with high chemical resistance, ductility, and enhanced elongation-at-break. Its pliable nature and strength mean that Nylon 11 can withstand impact, making it an excellent choice for defense, sports, and medical prosthetic applications.

TPU 95A is a thermoplastic urethane, with high levels of flexibility and tear strength. The material exhibits rubber-like qualities—much like a shoe sole—allowing for a range of end-use applications.

| Name and Standard Color | % Elongation at Break (XY, Z) | MPa Tensile Strength (XY, Z) | °C Heat Deflection (HDT @66 PSI, @264 PSI) | °C Melting Point |

|---|---|---|---|---|

Name and Standard Color HP MJF Nylon 12, Matte Gray | % Elongation at Break (XY, Z) 20%, 15% | MPa Tensile Strength (XY, Z) 48, 48 MPa | °C Heat Deflection (HDT @66 PSI, @264 PSI) 175°C, 95°C | °C Melting Point 187°C |

Name and Standard Color HP MJF Nylon 12 Glass-Filled, Matte Gray | % Elongation at Break (XY, Z) 10%, 10% | MPa Tensile Strength (XY, Z) 30, 30 MPa | °C Heat Deflection (HDT @66 PSI, @264 PSI) 174°C, 114°C | °C Melting Point 186°C |

Name and Standard Color HP MJF Nylon 11, Matte Gray | % Elongation at Break (XY, Z) 55%, 40% | MPa Tensile Strength (XY, Z) 52, 52 MPa | °C Heat Deflection (HDT @66 PSI, @264 PSI) 185°C, 54°C | °C Melting Point 202°C |

Name and Standard Color HP MJF TPU 95A, Matte Gray | % Elongation at Break (XY, Z) 400%, 90% | MPa Tensile Strength (XY, Z) 17, 8 MPa | °C Heat Deflection (HDT @66 PSI, @264 PSI) Shore A 90-95 | °C Melting Point 80, 35 |

How to Achieve the Highest Cost Savings

- Nylon 12 is a safe bet: parts printed in Nylon 12 will offer the highest cost savings when compared to the other MJF material options

- Forget minimum quantities: low quantities (of approximately 20 or less) will offer the same per part pricing as higher quantities

- Try designing small: parts measuring 4” x 4” x 4”—or otherwise fitting within a 4” box—could be 50% cheaper than before