5 Ways to Save on Medical Device Prototyping

Looking for tips on how to reduce the costs of medical device manufacturing? This article on efficient prototyping and design choices will help.

The medical field is often at the forefront of engineering, from advanced implants using biocompatible materials to prostheses that interface with the nervous system. Such advanced levels of engineering are possible only through rigorous design, prototyping, and testing regimes. Because medical technology is such a high-stakes venture, prototyping phases are critical to weeding out any design flaws that could result in life-threatening failures. This requirement for extensive prototyping and testing translates directly into increased costs. This article will outline ways of reducing costs of medical device manufacturing without affecting the quality and functionality of the prototype. The ultimate aim is to enable low-cost manufacturing of medical devices.

Tip #1: Choose the Right Material

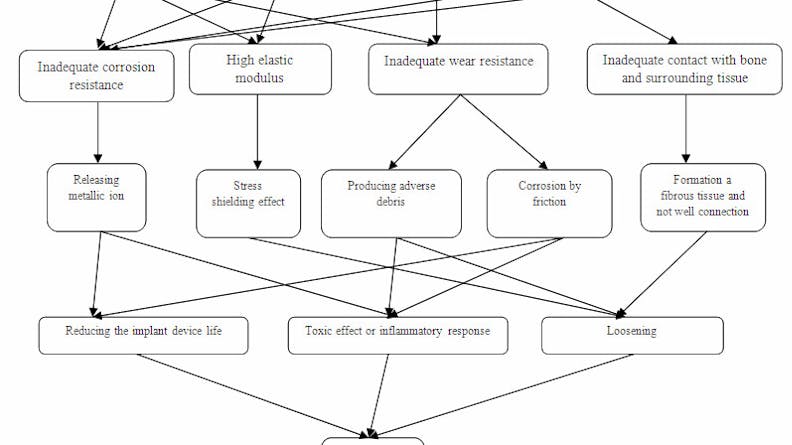

Medical devices are generally made from advanced biocompatible materials. An example of this would be a typical knee implant made from superalloys. The purpose of these advanced materials is twofold: they must not be rejected by the body, and they must be durable enough to meet the device’s intended lifetime.

During prototyping, it is important to choose the right material for every phase of the process. Proof-of-concept prototypes can be made from cheap materials like plastic or aluminum. Functional medical prototypes, on the other hand, need to be manufactured from the same materials that are to be used in the final product. This is to ensure they meet the relevant performance, usability, and manufacturability parameters of the final product. Significant savings can be attained by only using the materials that are necessary to fit the purpose of the prototype.

Example of material analysis of the different metallic biomaterials for knee and hip implants. (Image Source: Research Gate)

Tip #2: Choose the Appropriate Manufacturing Technology

Modern medical technologies are complex assemblies of advanced materials and sub-components. As such, their manufacture depends on a wide range of technologies. Prototyping often demands the fabrication of functional test articles, necessitating a variety of manufacturing methods such as:

- CNC machining - CNC machines offer precision, fast turnaround, and have a wide range of compatible materials.

- Sheet metal fabrication - Sheet metal components are cheap, durable and can accept a range of surface finishes or coatings.

- Plastic 3D printing - Printed parts allow for the manufacture of complex geometries with internal cavities and features not possible with other technologies.

- Injection molding - Injection molding offers unbeatable production rates and per-part costs. The tooling is expensive, however, so extreme care must be taken when designing parts intended for injection molding.

It is not financially feasible to keep a range of advanced machines to only manufacture one-off prototypes. These machines only pay for themselves if they are running continuous production cycles. A machine that sits around waiting to be utilized costs money instead of saving it. Outsourcing the manufacture of prototypes ensures that these overheads do not need to be maintained. It also provides flexibility to try different technologies if one does not produce the desired results.

Tip #3: Low-Cost Manufacturing for Medical Devices Using DFM

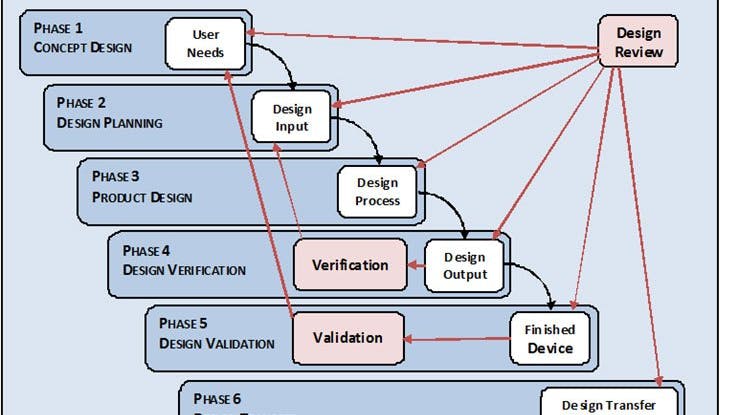

There is often a disconnect between the theoretical effectiveness of a design and the actual manufacturing of the parts. It is very difficult for design engineers to stay up to date on both their field of expertise and the realm of manufacturing technology. This disconnect can lead to parts that would meet all the end-use requirements, but which are not manufacturable. Proper use of Design for Manufacture (DFM) principles results in more efficient manufacturing for medical devices, which ultimately leads to reducing costs on medical device manufacturing.

Instead of forcing design engineers to be masters of both the medical equipment field and the manufacturing field, it is more efficient to outsource the DFM analysis to true manufacturing experts. Partnering with a company that has the expertise to analyze the designs and provide manufacturability insights can significantly save costs. Certainly, it’s not cost-effective to go through 90% into the design process only to realize that the product is impossible to manufacture or would rely on cost-prohibitive manufacturing technologies.

Illustration of how manufacturing integrates into the design process using DFM techniques. (Image Source: Research Gate)

Tip #4: Eliminate Feature Creep for Affordable Medical Device Design

Feature creep refers to all the additional items added onto a device that does not necessarily add to its core design requirements. Creep can take the form of added functions or increased manufacturing complexity for aesthetic purposes. While the elimination of added user functionality needs a thorough engineering analysis, manufacturing feature creep can only be eliminated by those with the relevant fabrication experience. They can highlight what features will add disproportionate costs to manufacturing which in turn will result in less affordable medical device design. Two of the main culprits are listed below.

- Tolerances - While parts that fit together without a visible part line may look impressive, they don�’t always serve a functional purpose. Adding excessive tolerance requirements onto a design can significantly increase the manufacturing cost. Limit tight tolerances to areas where they can be justified by engineering necessity.

- Surface Finishes - Highly-polished and mirror finishes are sometimes required in the medical field for cleanliness reasons. However, not all medical devices need this. Polishing is an expensive operation. Most parts will still be functional with less than class-A surface finishes.

Tip #5: Partner with a Prototyping Expert

As alluded to in the previous tips, the easiest method to achieve efficient manufacturing for medical devices is to partner with an expert in the field of medical prototyping. Many manufacturing facilities would happily manufacture parts based on your drawings. These parts will match the specifications with no fabrication flaws and will be machined to within the nearest micron. However, these manufacturers may not point out ways to reduce manufacturing complexity because it is simply not their job to do so.

Xometry specializes in prototype manufacturing and has the equipment and experience to manufacture the parts while also highlighting any pitfalls and providing valuable advice on how to achieve an affordable medical device design. This will reduce not only the cost of the prototype but also the overall cost of the device once it reaches the commercial sales phase. The cost savings made in the initial prototyping phase compound based on the number of devices that ultimately get sold, making this an extremely valuable step.