How to Create 3D-Printed Molds for Injection Molding

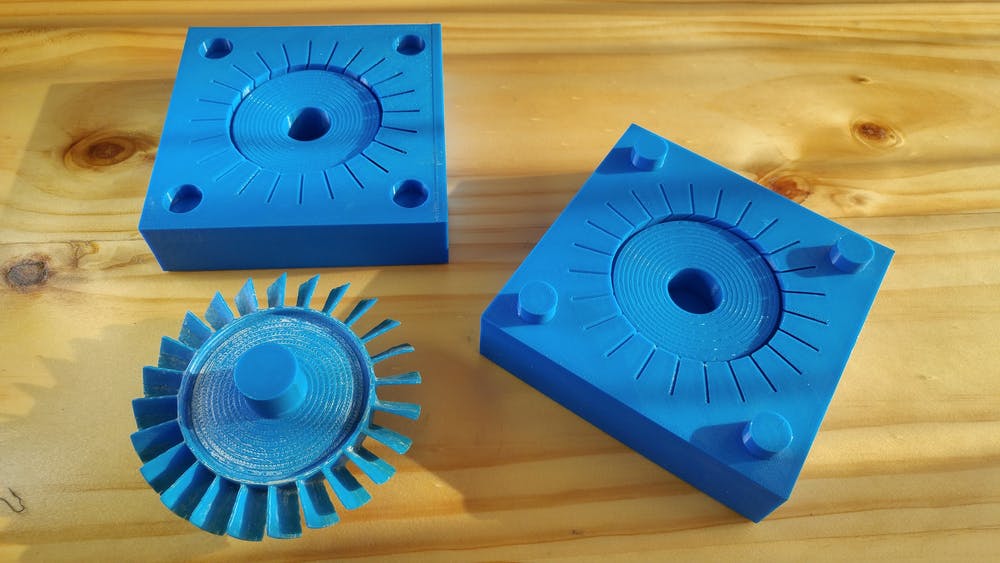

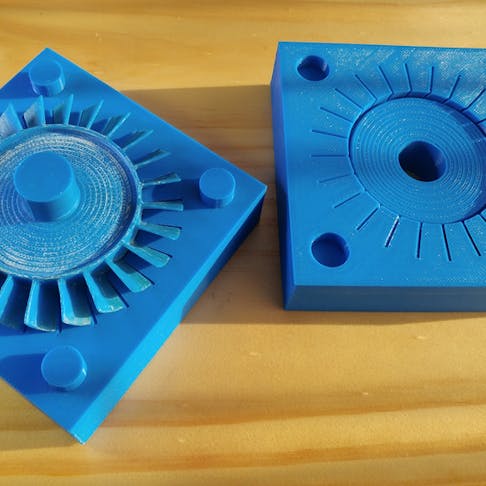

Injection molding is a popular manufacturing process used to produce parts in high volumes with consistent quality. The technology involves injecting molten plastic into a mold cavity. The mold, which is typically made from metal, determines the final shape of the product. However, the traditional method of creating these molds can be time-consuming and expensive, especially for small or custom production runs. 3D printing has emerged as a cost-effective and efficient solution to this problem. It allows manufacturers to quickly create molds with complex geometries and fine details, which would otherwise have been impossible to achieve with conventional manufacturing methods. Figure 1 are examples of 3D-printed molds:

3D-printed injection molds.

Image Credit: Shutterstock.com/GERMANJUNCA

In this article, we will explore the process of creating 3D-printed molds for injection molding and provide step-by-step guidance on how to produce high-quality molds using this innovative technology. We’ll also consider the advantages and disadvantages of 3D printing injection molds, and discuss other types of injection molds. Finally, there’s a section that answers some frequently asked questions that you might have about this innovative technology with regard to applying it to the injection mold industry.

So, let’s first take a look at the steps involved in creating a 3D-printed mold for injection molding:

1. Create the CAD Design

The first step in creating a 3D-printed mold for injection molding is to design the mold on Computer-Aided Design (CAD) software. The design should take into consideration factors such as: the part geometry, the material to be molded, the gate location, and the cooling channels.

When designing a mold for 3D printing, several tips can help reduce design challenges. Firstly, choose a suitable material for the mold. Ensure that the material is strong and stiff enough to withstand the pressure generated during the injection process. The mold should have a higher melting point than the material being injection molded. Secondly, mold design is critical in mold manufacturing. The inner surface of the mold should be oriented in such a way that it does not allow any contact with the printing support. Incorporating an air vent in the mold design can help expel trapped air during the injection molding process, reducing defects such as porous parts. Furthermore, using cooling channels will reduce cooling times.

When designing the part, also consider adding a draft angle. It is also important to ensure that the molded part will have uniform wall thickness and to avoid sharp corners. Injection molding flash is another factor to consider. Flash comes from extra material extruding past the parting line of the mold. To eliminate flash, incorporate runner systems into the mold design. Additionally, you can try post-design tweaks, such as increasing the clamping force and/or reducing the injection pressure.

2. Export the CAD Design File

After designing the CAD model of the mold, the next step is to export the design as an STL file. STL is a standard file format used for 3D printing. The STL file contains the 3D model of the mold, which can be imported into 3D printing software to prepare it for printing. Other file formats that can also be used for 3D printers include FBX, OBJ, 3MF, PLY, G-Code, X3G, and AMF.

3. 3D Print the Injection Mold

Once the STL file is prepared, the injection mold can be produced using a 3D printer. A number of different 3D printing processes can be used to produce the mold, including: fused deposition modeling (FDM), stereolithography (SLA), selective laser sintering (SLS), and digital light processing (DLP). The choice of 3D printer and the material used for printing will depend on factors such as the complexity of the mold and the desired lifespan of the mold.

FDM is often the most cost-effective 3D printing option for plastic molds and tooling. However, the resulting molds may have visible layer lines that require sanding or chemical finishing to remove. Resin-based 3D printing technologies, such as SLA and DLP, are more popular because they produce molds with a finer surface finish that requires less post-processing. Material jetting, another resin-based 3D printing method, can create molds in multiple materials and colors with a fine surface finish. SLS produces molds from reinforced nylon with both good strength and good surface quality.

4. Fit the Mold to the Metal Frame

Once the 3D-printed mold is complete, it must be fitted into a metal frame (mold base), to secure it during the injection molding process. The mold base includes the sprue bushing, which is where the molten material is injected into the mold.

The mold's configuration determines how it is fitted to the frame. There are two standard configurations used for 3D-printed molds for injection molding. The first configuration involves inserting the printed molds into an aluminum frame, providing stability, accuracy, and support for the molds. This configuration is considered better for producing precise injection molded parts and helps prevent molding defects like warping, maintaining the molds' integrity, and ensuring consistent pressure distribution during the injection molding process.

The second configuration involves fully 3D printing the molds without the use of an aluminum frame. While this eliminates the need for a frame, it requires more printing material, which can increase printing costs and time. Molds produced using this configuration are also more susceptible to defects such as warping due to the lack of support.

5. Start the Injection Molding Process

Once the mold is fitted to the metal frame, it is ready for the injection molding process. During the injection molding process, the mold is clamped shut, and molten material is injected into the mold through the sprue bushing. The liquid fills the mold cavities and takes on the shape of the part to be produced. After the material cools and solidifies, the mold is opened, and the part is removed.

What Are the Advantages of 3D-Printed Molds for Injection Molding?

3D-printed molds offer several advantages over molds made by traditional manufacturing methods, including:

- Cost-Effectiveness: 3D-printed injection molds are more cost-effective than those made by traditional methods for most applications. The plastic materials used to make the printed molds are less expensive than the aluminum and steel used for conventional mold fabrication techniques. In addition, 3D printing is a quick and inexpensive approach to mold production compared to the CNC machining traditionally used for mold manufacture.

- Ease of Use: No specialized expertise is required to print an injection mold using 3D printing technology. This reduces labor costs associated with conventional mold manufacturing processes, e.g. CNC machines.

- Suitable for Low-Volume Production: 3D-printed molds are better suited to low-volume production than CNC-machined molds. With 3D printing, it is possible to produce up to 10,000 parts depending on the material used to print the mold. The cost can also be up to 90% less than that for metal molds. The initial investment cost for 3D printers is also lower, and the mold materials (plastics, for example) are less expensive.

- Flexible Mold Design Process: The versatile nature of 3D printing technology offers great flexibility in designing molds. Mold designers and manufacturers can easily create and modify molds using 3D printing. Plastic-based 3D printing is ideal for situations where low costs and short lead times are essential, as well as for prototyping. This enables companies to iterate and test more quickly before moving to traditional tooling for large-scale production.

- Quick Turnaround: In addition to their high cost, aluminum or steel molds have long lead times. For instance, the production of a complex steel tool for injection molding can take several months, while an aluminum mold can require several weeks. In contrast, a 3D-printed mold, even a complex one, can be printed and prepared within a matter of days, offering a significantly shorter turnaround time.

What Are the Disadvantages of 3D-Printed Molds for Injection Molding?

3D-printed plastic molds for injection molding do have a few disadvantages, including:

- Shrinkage Defects and Warping: During cooling, 3D-printed molds can experience shrinkage and warping, which can cause problems with tight-tolerance products. This can result in defects in the mold and affect the quality of the final product.

- Experimentation Can Result in Waste: While 3D printing allows for easy design adjustments, there is a possibility of defects in the mold that may only be noticed at the end of the printing process, leading to more waste. While it is possible to recycle the waste, it can still be a drawback in terms of time and resources.

- Size Limitations: When it comes to size limitations, 3D-printed mold inserts are most suitable for small components with a volume of up to 164 cm3. In contrast, machined metal molds have a larger capacity and can easily accommodate parts measuring up to 966 cm3 for injection molding.

- Degradation: One drawback of 3D-printed inserts is their limited ability to withstand the high temperatures involved in injection molding, especially when using high-temperature polymers. Over time, the extreme conditions in the molding process can cause degradation and deformation of the 3D-printed inserts, making them unsuitable for high-volume production.

- Longer Cooling: Although the production time for 3D-printed molds is generally faster than traditional tooling methods, the injection molding process itself can take longer. This is due to the lower pressure and temperature resistance of 3D-printed molds compared to metal molds. The thermal conductivity of the polymers is also an issue. As a result, the cycle time for injection molding increases, leading to higher production costs and reduced manufacturing output.

How Important Is the Mold for Injection Molding?

The mold is a crucial component of the injection molding process. It is responsible for shaping the molten plastic material into the desired form, making it a critical factor in determining the final quality of the injection molded product. The mold defines the product's geometry, surface finish, and dimensional accuracy, making it a vital element in achieving the desired specifications.

The mold's design and construction also play a significant role in the efficiency and productivity of the injection molding process. A well-designed and properly constructed mold can increase the production rate, reduce material waste, and minimize the risk of defects in the finished product. In contrast, a poorly designed or constructed mold can cause production delays, increased material waste, and higher production costs. For more information, see our guide on What is Plastic Injection Molding.

Why Are 3D-Printed Molds Cheaper?

3D-printed molds are cheaper than their traditional metal counterparts for several reasons. First, the materials used for 3D printing, such as thermoplastics and photopolymers, are cheaper than traditional mold-making materials like steel or aluminum. Second, the 3D printing process is generally faster than traditional mold-making processes, such as CNC machining or casting, which reduces the overall production time and cost. Third, 3D printing eliminates the need for specialized tooling and equipment, which can be costly to purchase and maintain. Finally, 3D printing allows for the production of complex geometries that may be difficult or impossible to achieve with traditional mold-making methods, reducing the need for costly secondary operations. For more information, see our Guide to 3D Printing.

What Are the Factors to Consider When Using 3D-Printed Molds for Injection Molding?

The quality of the injection molding process depends heavily on the 3D-printed mold used. For that reason, there are several factors to consider during the design phase to ensure the success and efficiency of the printed product, including:

- Material Selection: The type of material used for 3D printing the mold is critical. It must be able to withstand the high temperatures and pressure of the injection molding process without warping or melting. Materials like nylon, ABS, and polycarbonate are commonly used for the 3D printing of injection molds.

- Design Considerations: The design of the mold should be optimized for 3D printing and injection molding. Certain design elements like wall thickness, draft angles, and gate location can affect the final product's quality and the mold's durability.

- Testing and Validation: Before using the 3D-printed mold for injection molding, it is essential to test and validate its performance. Testing can help identify any issues with the mold's design or material selection and allow necessary adjustments before part production begins.

- Production Volume Requirements: When considering the number of injection molding cycles, it's essential to recognize that 3D-printed molds are generally weaker than their metal counterparts, and are only suitable for low-volume manufacturing. Typically, they can only produce 30 to 100 runs before being replaced. This makes them an excellent choice for rapid prototyping but not for higher-volume production.

- Draft Angle: Draft angle is another crucial factor that plays a significant role in the injection molding process. Properly incorporating the right draft angle during mold design ensures easy ejection of the injection-molded part upon completion. A recommended draft angle of 1½ to 2 degrees can make it easier to remove molded parts.

- Size and Shape of the Mold: Size and shape are also important considerations when choosing a 3D-printed mold. Since these molds are generally smaller than CNC machined molds, it limits the size of the injection molded parts that can be created. Choose a mold type that can handle the size of the part you want to produce.

- Surface Finish: When it comes to surface finish, 3D-printed molds are not always the best option, as they are more prone to degradation than metallic molds due to the high temperature involved in the injection molding process. Also, 3D-printed molds present a rougher surface to the injected plastic than aluminum or steel molds. Aluminum or steel molds, which offer smoother finishing, are a better choice in such situations.

Post-processing is an option to improve the surface finish and accuracy of 3D-printed molds. Some post-processing techniques, such as sanding and polishing, can help to achieve a smoother surface finish. Alternatively, using a protective ceramic coating on the printed mold can reduce heat degradation issues and achieve a smoother finish.

What Are the Other Types of Injections Molding Processes?

There are different types of injection molding technology. Some of these techniques are listed and discussed in the sections that follow:

1. Gas-Assisted Injection Molding

The challenge with producing thick injection-molded parts out of plastic is that they may warp as they cool. Gas-assisted injection molding provides a solution to this problem by injecting gas, usually nitrogen, into an injection mold filled with plastic material. This enables the plastic on the mold's exterior to remain smooth and finished, while the interior becomes porous or hollow. This prevents the part from deforming during the cooling process and reduces the part's cost by reducing the amount of material used. It's used for creating parts with thick walls and complex geometries, reducing material usage and cycle times, and improving part quality. This process can be more expensive compared to other injection molding techniques.

2. Metal Injection Molding

Metal injection molding (MIM) uses a combination of powdered metal and binder material as the injection feedstock. The mixture is heated above the melting point of the binder so that the mixture can flow into the mold under pressure. When the binder cools, the "green" part is ejected. The binder material is burned out, and then the remaining metal is sintered at a suitable temperature to attain its final form. The technique is more costly than plastic injection molding and is typically used in specialized applications. For instance, metal injection molding is used in the cell phone industry to shield electronic components from radio or microwave interference.

3. 3D Printing

3D printing is not an injection molding technique. It is a method for directly creating parts using certain thermoplastics or metals by depositing them, layer by layer, onto a print bed. The significance of 3D printing in injection molding technology is that 3D printing can be used to produce the injection molds used to create multiples of the same part. Additionally, 3D printing can produce injection molds using plastic or metal. However, plastic 3D-printed molds are currently more common than metal 3D-printed molds.

4. Thermoplastic Injection Molding

Thermoset plastic injection molding is the most commonly used method of injection molding. Liquid silicone rubber and a suitable catalyst are injected into a hot mold which vulcanizes or sets the shape of the part within the mold. Such materials cannot be melted and recycled through the process. However, if you require a part that can withstand high temperatures or chemical agents, such as in medical devices or car parts, you may need to use liquid silicone injection molding.

5. Thin-Wall Molding

This type of injection molding involves creating plastic parts with walls that are typically thinner than 1 mm. Thin-wall molding is used to produce lightweight, high-volume parts that require minimal material usage. It finds applications in various fields such as: test apparatus, electronics, vessels, tubes, and other enclosures. To ensure that the thin wall geometry can withstand application conditions without any defects, plastic injection molders performing thin wall moldings must meticulously consider every aspect of the part design, mold design, and processing.

6. Unique Material Formulations

The use of unique material formulations enhances molding capabilities. Injection molding companies can use various additives, fillers, and specialized materials to create custom parts with unique properties, such as electrical conductivity, biocompatibility, or flame retardancy.

Can You Use PLA for Injection Molding?

No, you cannot use PLA (polylactic acid) for injection molding. PLA is a popular thermoplastic material used in 3D printing, but it is generally not suitable for injection molding. The reason is that PLA has a relatively low melting temperature compared to other commonly used injection molding materials like ABS, polycarbonate, and nylon.

In addition, PLA is more brittle and has lower impact strength, making it less suitable for injection molding applications where the molded parts are subjected to high stress or impact. PLA also tends to degrade at high temperatures and can release toxic fumes, making it unsuitable for use in the high-temperature and high-pressure environment of injection molding. For more information, see our guide on All About PLA 3D Printing Filament.

Can You 3D Print Molds for Injection Molding?

Yes, it is possible to 3D print molds for injection molding. 3D printing technology has made it easier and more affordable to create molds for injection molding. However, it's important to note that 3D-printed molds may not be suitable for all types of injection-molded projects, especially those involving high-volume production or those that require high-precision or high-strength molds. Nonetheless, 3D-printed molds can be a cost-effective and efficient option for low-volume or prototype production runs.

Are 3D-Printed Molds Used for Injection Molding More Expensive Than Traditional Molds?

No. In general, 3D-printed molds used for injection molding are less expensive than traditional molds. The cost of traditional molds is usually high due to the materials used, the design complexity, and the manufacturing processes involved. On the other hand, 3D printing technology has significantly reduced the cost of mold production by eliminating some of the expensive and time-consuming processes involved in traditional mold manufacturing.

The cost of 3D-printed molds can vary depending on factors such as the size and complexity of the mold, the printing technology used, and the materials used for printing. For example, using high-end 3D printing machines and materials can increase the cost of 3D-printed molds.

Summary

This article presented 3D printed injection molds, explained what they are, and discussed their various applications. To learn more about 3D-printed molds, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including 3D printing and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.