Top 20 Essential 3D Printing Tools for Optimal Results

3D printing as a hobby and profession has gained immense popularity in the last decade. Through the years, makers have picked up many tips, tricks, and tools that help improve 3D printing quality, save time, and make for an overall more enjoyable experience. There are many common tools that beginners might not be aware of, that can make all the difference in their 3D printing journey.

In this article, we look at 20 essential 3D printing tools for optimal results, as well as discuss a few common questions about 3D printing tools and accessories.

1. Fume Extraction System

Fume extraction systems are important for extracting harmful fumes when 3D printing. While materials such as PLA and PETG are generally considered safe to print with, other materials such as ABS, Nylon, and certain resins. Many 3D printer enclosures come with a fume extraction system already installed, but there are also several fume extraction systems for sale. There are also several DIY options available, that typically involve the use of fans and ducting. Figure 1 is an example of a fume extraction system:

Fume extraction system.

Image Credit: https://ultimate3dprintingstore.com/collections/fume-extractor/products/snapmaker-2-0-air-purifier

Fume extraction systems can be purchased for upwards of $500, while DIY options can cost less than $50, depending on the level of extraction needed and the materials used.

2. Blade

A blade can be an invaluable tool for dealing with support material or tight tolerances. The thin blade of a hobby knife or scalpel-like tool can be used to separate components in a print-in-place part if the tolerances are a little too tight. It can also be used for post-processing, such as removing print defects or support materials. Figure 2 shows an example of a hobby knife:

Hobby knife.

Image Credit: https://www.amazon.com/X-ACTO-2-Knife-Safety-Cap/dp/B000V1QV7O

High-quality hobby knives retail for anything from $8 and up, and typically feature replaceable blades for when a blade becomes worn or damaged.

3. Soldering Iron

A soldering iron is a versatile tool for 3D printing. It is typically used for smoothing prints, inserting heat inserts into a 3D printed part, and for welding components of a 3D print together. All three of these applications require some skill to do properly, so it is best to follow some tutorials or guides and practice on throwaway pieces, before attempting it on something important. Figure 3 shows an example of a soldering iron:

Soldering iron.

Image Credit: https://www.amazon.com/Hakko-temperature-limiting-soldering-FX600/dp/B006MQD7M4

Soldering irons can be picked up for as little as $16. Smoothing plastic can leave residue on the soldering tip, so it is best to use a cheap soldering iron, or a dedicated soldering tip when working with 3D printed parts.

4. Pliers

Pliers, and especially needle-nose pliers, are mostly used for removing supports, allowing you to get a strong grip on the support material. A pair of pliers can cost as little as $6. Figure 4 shows an example of needle-nose pliers:

Pliers.

Image Credit: https://www.amazon.com/Dykes-Needle-Pliers-Extra-6-Inch/dp/B0733NWRCS

5. Caliper

Calipers are used for verifying the accuracy of 3D printed parts, and to aid in designing new parts. They are typically used to measure other items to calculate dimensions when designing custom 3D-printed parts. Calipers can range in price from $6 to $100 depending on the length, materials used, whether they are digital or analog, and the level of accuracy. While the most expensive calipers are not strictly necessary, it is important to ensure that the calipers are accurate enough to be used effectively. Figure 5 shows an example of a digital caliper:

Digital caliper.

Image Credit: https://www.amazon.com/Digital-Caliper-Adoric-Calipers-Measuring/dp/B07DFFYCXS?th=1

Precision tweezer set.

Image Credit: https://www.amazon.com/HowFixit-Precision-Stainless-Anti-Static-Electronics/dp/B098FG8FZN

Precise tweezers can cost upwards of $5 for a set of two or three and are readily available on most major online retailers.

7. Cleaning Supplies

Cleaning supplies are important for ensuring print quality. The most basic cleaning supply needed is a good dishwashing soap for cleaning print beds. These dishwashing soaps contain degreasing agents, which clean any oils from the print bed, allowing for good bed adhesion. Print beds should be washed periodically, or if bed adhesion problems are noticed.

Other useful cleaning supplies include isopropyl alcohol and microfibre cloths. These can be used together to wipe clean the print bed after each print, helping to maintain good bed adhesion. Cleaning tools for the nozzle are also important. These can include a nozzle cleaning kit, which is basically a thin needle, a copper wire brush for cleaning the outside of the nozzle in case of stubborn filament sticking to it, and a damp cloth, which can be used for day-to-day cleaning of the nozzle. Figure 7 shows an example of a nozzle cleaning kit:

Nozzle cleaning kit.

Image Credit: https://www.amazon.com/FENGWANGLI-Printer-Cleaning-Needles-Tweezers/dp/B08PCJZ6SG

These supplies are relatively inexpensive and are commonly available from most major retailers. Even so, they are some of the most important tools for ensuring good print quality.

8. Lubricant

3D printers contain several moving parts that must be kept well lubricated to ensure print quality and prevent wear and tear of parts. The lubricants typically used on 3D printers depend on the components that need to be lubricated, and may include: PTFE-based lubricants, silicon-based lubricants, and lithium-based grease. The parts that require regular lubrication include: linear rails and rods, bearings and bushings, and gears. Figure 8 shows an example of a PTFE-based lubricant:

PTFE-based lubricant.

Image Credit: https://www.amazon.com/CRC-Registered-Lubricant-Technology-Plastic-Safe/dp/B0013J84BY/ref=sr_1_

Lubricants are relatively inexpensive, depending on the type, manufacturer, and area. Spending $5–$15 on lubricants should be enough to last for months of printing.

9. Glue Stick

Glue stick is another inexpensive consumable that can make a massive difference to print quality. These are typically used to improve bed adhesion. A layer of PVA glue stick can be applied to the print bed, and instantly improve the bed adhesion. Better yet, the adhesive layer lasts for multiple prints and is simple to reapply once it starts becoming ineffective. Be sure to use a PVA (polyvinyl alcohol) glue stick though, as other formulations may not work. Figure 9 shows an example of a glue stick pack:

Glue sticks.

Image Credit: https://www.amazon.com/Elmers-Disappearing-Purple-School-Washable/dp/B003ULCZ7M?th=1

Elmer’s Disappearing Purple Glue Stick, and UHU stic are two proven glue sticks that produce good results. They can be bought for as cheap as $8 for a box of 5 standard-size glue sticks.

10. Deburring Tool

A deburring tool is used to remove burrs from 3D-printed parts. The tool is relatively inexpensive and features replaceable blades. It is an invaluable tool for post-processing parts and ensuring smooth edges. Figure 10 shows an example of a deburring tool and blades:

Deburring tool and blades.

Image Credit: https://www.amazon.com/Deburring-Removal-Multifunctional-Removing-Handicrafts/dp/B0CNLMYQSC

Deburring tools can cost as little as $10, and come with a set of blades, and a plastic handle. A set of replacement blades costs around $8.

11. Sandpaper

Sandpaper is used to post-process 3D-printed parts. Certain types of filament, such as ABS (acrylonitrile butadiene styrene) and PETG (polyethylene terephthalate glycol), respond well to sanding. This technique can be used to achieve a very smooth surface finish. Typically, you can start with a coarse sandpaper to do the initial sanding, and then use higher grits and wet/dry sandpaper to achieve smooth surfaces. Figure 11 shows an example of a sandpaper set:

Sandpaper.

Image Credit: https://www.amazon.com/24PCS-Variety-Sandpaper-Assorted-Sanding/dp/B07R64PZ8N

Sandpaper is relatively cheap, with a set of sandpaper sheets from 120 grit to 3,000 grit costing as little as $5. Sandpaper sheets can be reused, although (with certain filaments) they may be prone to clogging, and would then need to be replaced.

12. Air Filtration System

Air filtration systems are an extremely important part of protective equipment. These become necessary when printing with certain materials that give off harmful fumes when heated, such as ABS. Air filtration systems should ideally have both an activated carbon filter, as well as a MERV (minimum efficiency reporting value) or HEPA (high-efficiency particulate air) filter, to filter out particulates and VOCs (volatile organic compounds). Figure 12 shows an example of a precision air purifier:

Air filtration system.

Image Credit: https://www.amazon.com/LEVOIT-Purifiers-Bedroom-Allergies-Core300S-P/dp/B08L73QL1V?th=1

These filter systems can cost upwards of $80 for an air purifier with replaceable HEPA and carbon filters. These filters will need to be replaced periodically according to manufacturers’ instructions.

13. Nozzles

Nozzles are used in FDM (Fusion Deposition Modeling) printers to direct the extruded filament. Nozzles come in various diameters for different filament or output sizes, as well as different materials and styles. It is always wise to keep a few spare nozzles lying around in case the nozzle currently in use clogs up. Different styles of nozzle or materials can also be used to achieve better performance, although these nozzles usually come at a higher price point. Figure 13 shows an example of 3D printer nozzles:

3D printer nozzles.

Image Credit: https://www.amazon.com/Printer-Nozzle-0-4mm-Extruder-Brass/dp/B07CB7VYB2

3D printing nozzles can range anywhere from $15 for 30 nozzles, to $100+ for a single nozzle, depending on the manufacturer, style of nozzle, and materials used.

14. Filament Storage

Filament storage is a key component of 3D printing that is often overlooked. 3D printing filament should be kept as dry as possible. Certain filaments, such as PETG and nylon are especially hygroscopic and absorb moisture readily. Therefore, filament should be stored in an environment that is as moisture-free as possible. Figure 14 shows an example of a filament storage solution:

Filament storage system.

Image Credit: https://www.amazon.com/IINCOOY-Printer-Filament-Filaments-Moisture-Resistant/dp/B0C1MJYK74?th=1

Solutions for storing filament include anything from DIY options that use boxes or enclosures with reusable or disposable desiccant, to purpose-built storage containers. Depending on which option you choose, filament storage can cost upwards of $20 per spool.

15. Cable Organizers

3D printers have a range of cables that are used to power and control the various components of the printer. Cable organizers can help keep the printing space organized, and ensure that cables do not get in the way of a print. There are various options available to hide cables or attach them to structural components of the printer, ensuring that they do not obstruct the printer during operation. Figure 15 shows an example of a cable organizer:

Cable management system.

Image Credit: https://www.amazon.com/Fanoshon-Computer-Management-Organizer-Protector/dp/B09P7ZX3L1?th=1

Cable organizers can range from a few dollars for cable ties, to upwards of $10 for cable organization sleeves or systems.

16. Hex Key Wrench Set

3D printers inevitably contain some hex nuts or threaded inserts to join components together. A hex key wrench set is an invaluable tool for assembling, upgrading, or maintaining a 3D printer. Hex key wrench sets can be obtained for $10 and up, depending on the material and amount of wrenches in the set. Figure 16 shows an example of a hex key wrench set:

Hex key wrench set.

Image Credit: https://www.amazon.com/TEKTON-Long-Wrench-13-Piece-25232/dp/B00I5TGX3Q?th=1

17. Adhesive Solutions

Sometimes, a 3D printed part needs to be printed in sections, instead of one cohesive print. In this case, adhesives are needed to attach the sections and ensure a strong bond. Different options for joining 3D prints include: superglue, epoxy, plumber’s cement, acetone, 3D pens, and hot glue guns. Certain adhesive solutions, such as acetone, are only suitable for specific materials, such as ABS. Figure 17 shows an example of a superglue:

Superglue.

Image Credit: https://www.amazon.com/Gorilla-Super-Glue-Gram-Clear/dp/B001IY82FM?th=1

Depending on the type and amount of adhesive solution chosen, it can cost anything from $10 and upwards.

18. Adjustment Tools

“Adjustment tools” is just a name for any tools used to make adjustments to the 3D printer. This may include level gauges, measuring blocks, screwdrivers, or anything else used to calibrate and adjust the 3D printer. Figure 18 shows an example of a setup block set:

Setup block set.

Image Credit: https://www.amazon.com/Blockcision-Setup-Blocks-Woodworking-Tools/dp/B09TMX116R

These tools vary wildly in cost, depending on the type of tool, the manufacturer, and the materials used. It is typically best to purchase these tools as needed, as you will most likely have many of these tools already.

19. Filament Dryer

A filament dryer is a tool used to dry filaments to printable moisture levels. It can be incredibly useful if you live in a humid environment and use hygroscopic filaments, such as PETG or nylon. Moisture in filaments can completely ruin a print and even cause clogs that are severe enough to require a new nozzle. Figure 19 shows an example of a filament dryer:

Filament dryer.

Image Credit: https://www.amazon.com/Creality-Dust-Proof-Moisture-Proof-Filaments-Accessories/dp/B0CGWP81MQ

Filament dryers can cost $50 up to $150+, with certain models able to dry up to four spools at once.

20. Resin Scraper

Resin scrapers are used to clean the print bed of resin. They are designed to be strong enough to remove the resin from the print bed, but soft enough so as not to damage it. They are also used to help remove a 3D print from the print bed. Figure 20 shows an example of a resin scrapers:

Resin scraper.

Image Credit: https://www.amazon.com/Printer-Scraper-Flexible-Photosensitive-Stripping/dp/B0CLVNZC57

Resin scrapers can be 3D printed for a few cents, or purchased for anywhere from $10 and up.

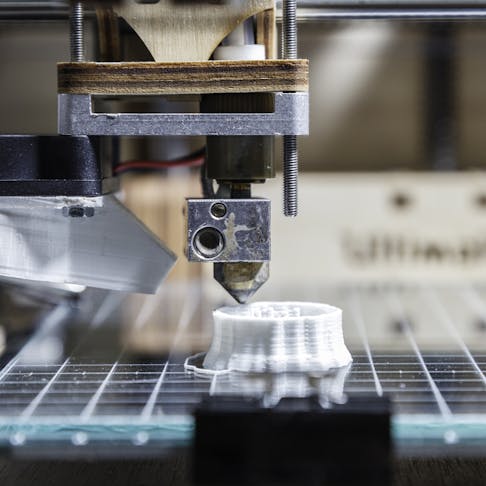

What Is 3D Printing?

3D printing is an additive manufacturing process, in which a material is deposited layer by layer and fused to form a part. FDM, or extrusion printing, is one of the most popular methods of 3D printing, in which plastic filament is melted and extruded onto a print bed. The extruder moves around above the print bed, depositing the melted filament in layers, after which it cools and hardens, forming the part.

To learn more, see our full guide on How 3D Printing Works.

What Is the Use of 3D Printing Tools and Accessories?

3D printing tools and accessories are used in specific applications to fulfill certain needs. For most of these tools, there are workarounds and alternatives, but the tools listed are proven to produce excellent results for their specific needs. For example, tweezers aren’t strictly needed to remove internal supports from a print. However, there isn’t a good alternative that provides the required precision and strength to remove hard-to-reach internal supports safely.

What Is the Importance of Having All the 3D Printing Tools and Accessories?

Each of the 3D printing tools and accessories listed above has a particular role in the 3D printing process. Some of these tools are only applicable to certain types of 3D prints, such as pliers which are mainly used to remove supports. While these tools are not strictly necessary, they are all proven to help improve the ultimate quality of a 3D-printed part when used for the correct application.

While there are workarounds for most of the tools listed, having the proper tools goes a long way to improving print quality, saving time, and ensuring an effective workflow.

What Are the Different Materials That Are Used for 3D Printing?

There is a wide variety of materials that are used for 3D printing, such as:

- PLA: Polylactic acid, commonly known as PLA, is the easiest material to print with when using an FDM 3D printer. PLA is a bioplastic, made from renewable sources, which makes it biodegradable and safe to print with. It produces high-quality prints that are rigid and strong, but do not offer much resistance to temperature, chemicals, or UV radiation. This makes it suitable for prototyping and limited indoor usage.

- PETG: PETG, or polyethylene terephthalate glycol, is another popular plastic filament. Its low melting temperature makes it relatively easy to print with, albeit not as easy as PLA. It has good resistance to heat, UV, and chemicals, and decent strength, making it suitable for production parts. PETG filament is quite hygroscopic, attracting moisture which can completely ruin print quality. Therefore, proper storage and/or drying out of PETG filament is very important to achieve acceptable results.

- ABS: ABS, or acrylonitrile butadiene styrene, is a plastic filament that produces tough, durable parts with high heat and impact resistance. ABS is the material of choice when producing functional plastic parts that are durable enough to withstand real-world conditions. Unfortunately, ABS is one of the trickier filaments with which to achieve good results. It requires high nozzle and bed temperatures, as well as an enclosure to achieve good printing results. Additionally, printing with ABS produces toxic fumes which can lead to health hazards, so proper ventilation and filtration are required.

- Resins: Plastic resins are used in stereolithography, or SLA, printing. This method of printing produces some of the highest accuracy and resolution, as well as surface finish, making it a popular form of 3D printing for professional applications. There are many types of resins with different properties, ranging from draft resins which can print with incredible speed, and polyurethane resins, which produce extremely durable and strong plastic parts for industrial applications.

- Metal: Metal 3D printing has the potential to revolutionize many industries, allowing for complex geometries that are impossible to achieve with traditional manufacturing techniques. Titanium, stainless steel, and aluminum can all be 3D printed, using either FDM or SLM techniques.

How Do the 3D Printing Tools and Accessories Affect the 3D Print Outcome?

3D printing tools and accessories can have a massive effect on the outcome of a 3D-printed part. Certain tools, such as proper cleaning supplies, nozzles, filament dryers, or glue sticks, affect the quality of the print directly. Other tools such as pliers or sandpaper, play a role in the post-processing of a 3D print, ensuring a good surface finish. Using the correct, high-quality tools for the job can mean the difference between a good 3D print, and a poor one.

Do Different Types of 3D Printing Require Different 3D Printing Tools and Accessories?

Yes, different types of 3D printing require different 3D printing tools and accessories. Extrusion printers and resin printers, the two main types of 3D printers, require tools and accessories that are unique to the style of printing they represent. For example, glue sticks are useful for extrusion printing, to improve print-bed adhesion. However, resin printers do not have a comparable print bed, so a glue stick is not needed for resin printing.

To learn more, see our full guide on Types of 3D Printing Processes.

Where Can I Buy 3D Printing Tools and Accessories?

3D printing tools and accessories can be bought from several specialized and general retailers. Amazon has a wide selection of specialized tools available for 3D printing, but many common tools can be bought from retailers such as Target or Walmart. Specialized equipment can be bought online directly from manufacturers such as Ultimaker or Creality, or several specialist 3D printing stores.

How To Choose the Best 3D Printing Tools and Accessories To Buy?

Choosing the best 3D printing tools and accessories to buy can be heavily dependent on your 3D printing setup, budget, and needs. One approach is to try and buy the most basic and versatile tools first, focusing on high-value-for-money options. The more niche tools can be bought as and when you need them. Many 3D printing tools can be bought very cheaply, but it is important to discern when you need to spend more to get high-quality tools. Measuring tools such as calipers are a good example of where you need to spend the money to get a high-quality tool, as low-quality calipers can lead to inaccurate measurements.

Online reviews, forum posts, or word-of-mouth recommendations are all good ways to gauge what 3D printing tools are really necessary, as well as where it is ok to save money, and where it isn’t.

Is It Necessary To Buy All the 3D Printing Tools and Accessories for Beginners?

Beginners don't need to buy all the 3D printing tools and accessories. The best approach would be to buy tools and accessories as they are needed or opt for tools that seem to provide the best value for money. Some of the more-expensive accessories, such as specialized filament storage, can be self-made using several DIY methods found online. This may be a good option for someone starting with 3D printing.

Summary

This article presented essential 3D printing tools, explained each of them, and discussed their various uses and importance. To learn more about 3D printing tools, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including 3D printing tools and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.