PLA 3D Printing Service

Get instant online quotes on PLA 3D printed parts. Free shipping on all US orders. ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified.

Xometry offers the highest quality PLA 3D printing service for both prototyping and end-use applications. Polylactic acid, or PLA is one of the oldest thermoplastics made from chains of lactic acid and/or lactide monomer units. It is recyclable, easily worked, and aesthetically pleasing, making it one of the most common plastics in industry. PLA is an ideal thermoplastic for fused deposition modeling (FDM) 3D printing as it extrudes well, has good intra-layer bonding, and is tolerant to a broad range of temperatures. Xometry’s online 3D printing service offers PLA parts that can be used for rapid prototyping, aesthetic applications, as well as production parts for a variety of industries. If interested in Xometry’s online 3D printing service, upload a CAD file of your part to our Instant Quoting Engine and Xometry will provide instant quotes for all of our 3D printing services and manufacturing processes.

What is PLA?

Polylactic acid, or PLA for short, is a thermoplastic polyester built from the lactic acid and cyclic di-ester lactide monomer units. These units come from fermenting plant materials like cassava, sugar cane, corn, or beets, where these building blocks are then polymerized using either metallic catalysis and/or through condensation reactions (i.e. the monomers bond together, releasing water in the process).

PLA is a chiral molecule, meaning that its molecule comes in two reflected forms or enantiomers (think about how your hands are reflections of one another, but still have all the same features). A mixture of both types of PLA is known as racemic PLA which has different properties than the so-called “pure” PLA (of either its D or L enantiomers, known as PDLA or PLLA respectively). These differences depend on production method and intended application, but generally they change the thermoplastic’s crystalline nature where racemic mixtures are more amorphous and pure versions are highly crystalline.

PLA readily undergoes hydrolysis, thermal degradation, and photodegradation at temperatures above 60 °C (140 °F) making it easier to degrade and recycle than other plastics. Combined with its renewable starting materials, PLA is overall a much more environmentally friendly material. In recycling, PLA is denoted by the “7” SPI resin identification code.

For more information, see our guide on PLA 3D Printing Filament.

Characteristics of PLA

Generally speaking, PLA is a safe, workable, and highly aesthetic plastic that is ideal for 3D printing beginners and experts alike. Below is a table that contains the material properties of PLA for additive manufacturing. Note that this table is generalized and specific 3D printing PLA grades will typically have their own unique properties.

| Material Property | Value (unit) |

|---|---|

Material Property Heat Deflection Temperature (HDT) | Value (unit) 126 °F (52 °C) |

Material Property Density | Value (unit) 1.24 g/cm³ |

Material Property Tensile Strength | Value (unit) 50 MPa |

Material Property Flexural Strength | Value (unit) 80 MPa |

Material Property Impact Strength (Unnotched) IZOD | Value (unit) 96.1 J/m |

Material Property Shrink Rate | Value (unit) 0.37-0.41% (0.0037-0.0041 in/in) |

Here are the recommended printer settings for PLA as well as the specifications and capabilities of Xometry’s FDM 3D Printing Service:

| Printer Settings | Value |

|---|---|

Printer Settings Extruder temperature | Value 200 °C |

Printer Settings Bed temperature | Value Between 50-70 °C |

Printer Settings Nozzle Temperature | Value Between 50-70 °C |

Printer Settings Print speed | Value 30-90 mm/s |

Printer Settings Extruder fan speed | Value 100% |

Printer Settings Retraction speed | Value Between 30-80 mm/s |

Printer Settings Retraction distance | Value

|

Printer Settings Flow of filament | Value Reduce in 5% increments |

Printer Settings Layer height | Value 0.2 mm for standard speed and quality |

Printer Settings Print Bed | Value Level |

Printer Settings Bed material | Value Best with glass, aluminum, and BuildTak |

| Tolerance Note | Description |

|---|---|

Tolerance Note General Tolerance | Description +/- a single build layer thickness for the first inch and +/- .002” for every inch thereafter. |

Tolerance Note Build Size | Description Up to 24" x 36" x 36" |

Tolerance Note Layer Height, less than 16" | Description 0.008" |

Tolerance Note Layer Height, greater than 16" (up to 36") | Description 0.013" Layers |

Tolerance Note Minimum Wall Thickness | Description 0.047"(less than 16"), 0.060" (greater than 16") |

FDM 3D printed parts can be built up to 24" x 36" x 36". Stratasys Fortus 400/450-series machines will produce parts up to 16" and Stratasys Fortus 900MC or F900 platforms are used for parts larger than 16". Prototyping PLA is built on Prusa MK3S/MK4 or Bambu Lab X1C desktop FFF machines with a build volume of 9.8" x 8.3" x 8.3. General tolerances apply before secondary finishing or post-processing unless otherwise specified. To learn more tips about FDM 3D printing check out our Fused Deposition Modeling (FDM) Design Guide.

Ready to start making custom PLA 3D printed parts?

Advantages of PLA 3D Printing

- Excellent intra-layer bonding - PLA creates strong parts thanks to the enhanced bonding between layers in a print, minimizing anisotropy. This is due to PLA’s lower melting temperature and increased stability throughout its temperature range..

- Reduced warping/curling - PLA 3D printing does not warp or curl as easily as other materials thanks to its low thermal expansion and shrink rate.

- Safe and non-toxic - PLA is built from molecules that are 100% safe for humans, and does not release harmful gasses when burned or melted, making it one of the safest plastics to work with.

- Highly aesthetic - PLA can achieve high gloss and a good transparency, and also dyes well.

- Easily blended with additive materials- PLA readily accepts additives allowing for polymer blends, carbon fiber parts, metal parts, and much more.

- Environmentally friendly - PLA is made using renewable materials (plant matter), is readily recyclable with the right industrial composting set up, making it a fully sustainable form of plastic.

Disadvantages of PLA 3D Printing

- Recycling issues - Though recyclable, PLA must be brought to sufficiently high temperatures to degrade and must be in the right conditions (enzymes, agitation, etc.). Putting PLA in a regular landfill or compost pile slows decomposition to that of other plastics, so only industrial composting setups will degrade PLA. Not only this, but the various additives in certain PLA blends will change how it recycles, and may cause the material to be wholly unrecyclable.

- Low melting temperature - PLA’s low melting temperature prevents it from being used in high-temperature applications.

- High moisture/oxygen permeability - PLA’s high permeability makes it unsuitable for marine applications and other harsh environments that will degrade the plastic.

- Price - PLA (especially unique 3D printing blends with additives) can be more expensive than other plastics. Part cost can also be high if high-volume part production is necessary.

- Relatively weak - in comparison to similar plastics like ABS, PLA is weaker and less durable.

3D Printing Technologies for PLA

- FDM

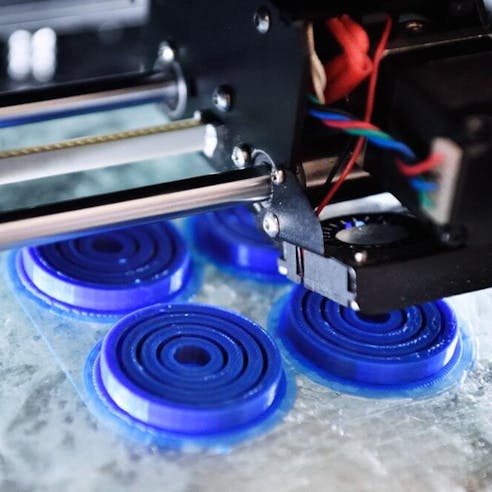

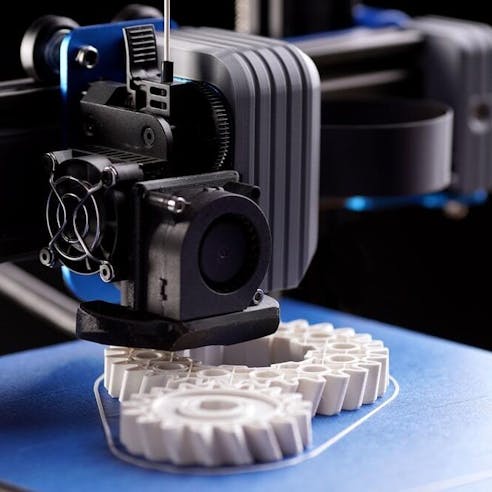

FDM

PLA is one of, if not the best material for 3D printing with fused deposition modeling technology. In FDM 3D printing, PLA filament is fed into a heated extruder head that is controlled by a computer-guided XYZ gantry to print 3D parts in a layer-bylayer process. It is the most common 3D printing technology for both hobby and professional users, and PLA filament is by far the most popular and compatible material for FDM technology thanks to its working characteristics. To learn more, visit our capability page on Xometry’s FDM 3D Printing Service.

Common Uses of PLA 3D Printed Parts

Common uses of PLA include:

- Rapid prototyping - PLA is regularly used to quickly print out prototype parts for product development in as little as a few hours up to just a few days. Its dimensional stability mixed with its aesthetics make it ideal for capturing the idea of a part or product with little to no user input needed.

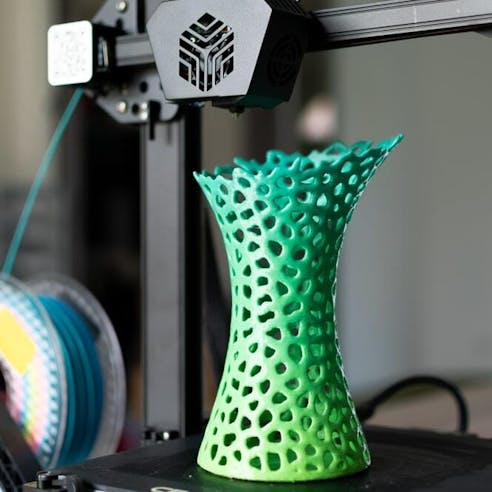

- Decorative/presentation parts - PLA’s high gloss finish and color options make it great for decorations, models, figurines, displays, and presentation parts made with 3D printing.

- Jigs/fixtures - Jigs and fixtures can be difficult to make and are prone to damage. By 3D printing PLA jigs and fixtures, operators have the freedom to iterate on the best fixture device for their fabrication process, and can easily replace damaged prints instead of manually crafting a new one.

- General containers/molds - 3D printed PLA work well for containers and molds for one-off fabrication processes like casting orcuring. Its high gloss finish prevents unwanted surface defects and they can be made into nearly any desired shape, allowing designers to create parts out of other materials quickly and with fewer post-processing steps.

Alternatives to PLA 3D Printing

Suitable alternatives to PLA in Xometry’s FDM online 3D printing service include:

- ABS

- Nylon

- PP

- PC

- PC-ABS

The above materials are beneficial when PLA’s lack of strength, absorption issues, or low melting temperature starts to negatively impact your project.

If 3D printing is not the right process but PLA is the right material, then there are other manufacturing processes at Xometry that can help achieve the right parts.

Plastic Injection Molding

Plastic injection molding can create a large quantity of PLA parts in a short time, and can achieve highly complex geometries with little variation. Using this service with Xometry allows you to own both the tooling and the molded parts, and offers great tolerances without needing to invest in expensive injection molding equipment. To learn more, view our capability page on Xometry’s Custom Plastic Injection Molding Service.

Sheet Cutting

Sheet cutting offers a high volume of unique parts from the same stock piece, and achieves some of the most efficient and precise cuts available. PLA sheets can be engraved, marked, or cut using a variety of sheet cutting techniques such as laser cutting, waterjet cutting, or others. Sheet cutting with Xometry is as easy as sending a CAD file with your designs, and Xometry can also offer finishes, assembly, and more. To learn more, view our capability page on Xometry’s Sheet Cutting Service.

Why Choose Xometry for PLA 3D Printing?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

We are ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified.