Rare-Earth Metals: Definition, Properties, Use, and Types

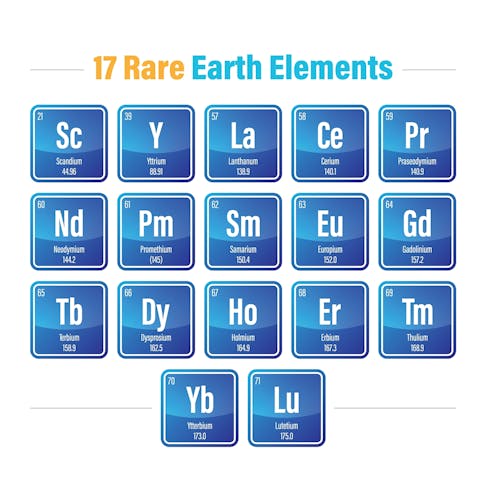

Rare-earth metals, also referred to as rare-earth elements (REEs), are a group of seventeen naturally occurring chemical elements. Most are found on the periodic table’s F block. They possess unique properties that make them valuable in various technological applications. Rare-earth metals exhibit high magnetic strength, luminescence, and catalytic properties.

The most common types of rare-earth metals include lanthanum, cerium, and neodymium. These elements are crucial components in electronics, renewable energy technologies, and automotive catalysts. Despite their name, rare-earth metals are not rare in terms of overall abundance but are often dispersed and difficult to extract economically.

What Is Rare-Earth Metal?

Rare-earth metals, or rare-earth elements (REEs), are a group of seventeen chemical elements. They exhibit high magnetic strength, luminescence, and catalytic properties. Despite the name, rare-earth metals are not rare in terms of abundance but are often dispersed and difficult to extract from raw ores.

What Are the Different Properties of Rare-Earth Metals?

The properties of rare-earth metals are discussed below:

1. High Magnetic Susceptibility

Rare-earth metals exhibit high magnetic susceptibility — they can be easily magnetized when exposed to an external magnetic field. This property is crucial for MRI machines and magnetic storage devices.

2. Catalysis

Their electron configurations make rare earths into powerful chemical catalysts. They’re thus vital in petroleum refining and environmental cleanup processes. The specific electronic configurations and atomic structures differentiate each rare-earth element from the others.

3. Strong Coordination Complex Formation

Coordination complex formation refers to an element’s propensity to form stable complexes with ligands. This property is crucial in catalysts and magnetic materials. It enhances the metals’ effectiveness in chemical reactions and material applications. However, excessive coordination can hinder solubility and lead to environmental concerns. Understanding the nuances of coordination chemistry will help you optimize rare-earth metal utilization while mitigating potential drawbacks.

4. Unique Optical Properties

Some rare-earth metals display unique optical properties, including fluorescence and phosphorescence. These properties are vital in applications such as lighting, display technologies, and medical imaging.

Fluorescence is the immediate emission of light upon excitation, while phosphorescence is a delayed emission after excitation. Luminescence is the overarching term for both fluorescence and phosphorescence phenomena. Rare earths are thus useful in energy-efficient lighting and medical diagnostics, but there are also environmental concerns due to mining and processing challenges.

5. Crucial for Magnets, Electronics, Lasers, and Phosphors

Rare-earth metals enable the production of powerful magnets used in motors, generators, and MRI machines. In electronics, they enhance performance and efficiency, contributing to the miniaturization of devices. In lasers, rare-earth metals enable precise light emission, essential for medical procedures and telecommunications.

They are also essential in phosphors, which produce vibrant colors in display screens and lighting systems. Each property offers unique advantages. But again, the extraction, processing, and environmental impact of rare earths demand careful management.

6. High Melting Points for High-Temperature Applications

Rare-earth metals possess high melting points, making them suitable for high-temperature applications in aerospace and metallurgy industries. This property ensures stability and durability under extreme conditions. Each rare-earth metal has a specific melting point, allowing for tailored usage. While high melting points are advantageous for heat-resistant materials, it also means their production is very energy-intensive.

What Are the Uses of Rare-Earth Metals?

Rare-earth metals are used in various industries, including electronics, renewable energy, and automotive sectors. They are essential to high-performance magnets used in electric vehicle motors and wind turbines. Additionally, rare-earth metals are crucial parts of efficient lighting systems, such as LED and fluorescent lights. The electronics industry relies on rare-earth metals for components in smartphones, computers, and other devices.

Which Industries Uses Rare-Earth Metals?

The electronics industry extensively uses rare-earth metals. They are crucial components in the production of smartphones, computers, and other electronic devices. They enable miniaturization, enhance performance, and improve energy efficiency in electronic gadgets.

Additionally, rare-earth metals are vital parts of renewable energy technologies such as wind turbines, solar panels, and electric vehicle batteries. Their magnetic and catalytic properties contribute to the efficiency and sustainability of these energy systems.

What Are the Different Classifications of Rare-Earth Metals?

Rare-earth metals are typically classified into two main groups: light rare-earth elements (LREEs) and heavy rare-earth elements (HREEs). LREEs include elements with atomic numbers from 57 to 64, while HREEs encompass those with atomic numbers from 65 to 71.

This classification indicates the properties and behavior of each element. LREEs are more abundant and common in everyday applications, while HREEs are rarer and find specialized uses in advanced technologies.

What Are the Different Types of Rare-Earth Metals?

The types of rare-earth metals are listed and discussed below:

1. Gadolinium

Gadolinium is a rare-earth metal with a high melting point and excellent neutron capture ability. It is commonly used in magnetic resonance imaging (MRI) machines as a contrast agent. Unfortunately, it can also be toxic. Gadolinium's neutron capture ability differentiates it from the rest and its cost is moderate.

2. Yttrium

Yttrium stabilizes other elements and is used in phosphors for color television tubes, energy-efficient light bulbs, and lasers. It is one of the rarer lanthanide elements, but the stabilizing effects it has on materials makes it important. It can be had for moderate prices.

3. Neodymium

Neodymium is valued as a strong permanent magnet. However, on its own it is vulnerable to corrosion. Spinning hard disk drives use neodymium. It is sold for moderate prices.

4. Scandium

Scandium is known for its low density and high melting point, making it suitable for aerospace components and sports equipment. The downside is that it’s expensive to produce. Scandium's low density, high melting point, and high cost set it apart from most others.

5. Lanthanum

Lanthanum has a high refractive index and is used in camera lenses, petroleum refining, and rechargeable batteries for hybrid vehicles. Outside of those realms, though, it has few commercial applications. Lanthanum's differentiation lies in its refractive index, and its cost is moderate.

6. Erbium

Erbium amplifies light signals and is crucial in fiber optic communication systems, telecommunications, and laser applications. It’s thus an important element, but it’s expensive to procure.

7. Cerium

Cerium is widely used in catalytic converters to reduce harmful emissions. Cerium oxide is also good for polishing glass, but that’s one of the few non-catalysis uses for the element. Its cost on the market is moderate.

8. Ytterbium

Ytterbium acts as a radiation source in nuclear medicine, lasers, and industrial processes. It absorbs and emits light in predictable wavelengths, but the commercial uses for the element are limited, so its value on the market is moderate.

9. Lutetium

Lutetium is used in cancer treatment and as a catalyst in chemical reactions due to its stable isotopes and predictable radiation. Lu-176 is the only unstable isotope, but its half-life is measured in billions of years, making it good for dating meteorites. Though more common than silver in the Earth’s crust, it is still expensive.

10. Europium

Europium forms the red phosphors for television screens and LED bulbs. This fluorescence is its main commercial value, so it sells for moderate prices.

11. Holmium

Holmium is employed in nuclear control rods, lasers, and medical devices for its ability to absorb neutrons and emit radiation. This expensive element has few other commercial uses.

12. Thulium

Thulium is used in portable X-ray devices, lasers, and high-temperature superconductors due to its magnetic and electrical properties. Like many rare earths, it’s only employed in specialized fields. Thulium is typically expensive.

13. Samarium

Samarium is utilized in headphone and speaker magnets, as well as in nuclear reactors for its neutron-absorbing properties. Its going price is moderate.

14. Praseodymium

Praseodymium is crucial for creating powerful magnets for electric vehicle motors, wind turbines, and audio speakers. Though increasingly important, the supply is relatively limited and the prices are in the moderate range for rare earths.

15. Terbium

Terbium is vital for the green phosphors in color display screens and energy-efficient lighting. It’s thus found in many televisions and fluorescent lamps. However, these phosphorescent properties have few other commercial uses. Terbium sells for moderate prices.

16. Dysprosium

Dysprosium improves the magnetic properties and efficiency of electric vehicle motors and wind turbines. The element is in short supply, but current prices are still moderate.

17. Promethium

Promethium has no stable isotopes, so it’s exceedingly rare in nature. The radiation from Pm-147 gets employed in atomic clocks and high-precision thickness-measuring equipment. It can also go into phosphorescent paint. Most must be synthesized from uranium or neodymium, so it is expensive.

How To Choose Which Type of Rare-Earth Metals to Use

The following process will help you decided which rare-earth metal you need;

- Identify the specific properties required for your application, such as magnetic strength, luminescence, or catalytic activity.

- Evaluate the availability and cost of the rare-earth metals that can serve your purposes.

- Consider the environmental impact and sustainability of your chosen rare-earth metals.

- Assess its compatibility with other materials in your system or product.

- Research the performance and reliability of each rare-earth metal in similar applications.

- Consult experts or suppliers to gather insights and recommendations.

- Conduct thorough testing to validate whether the metal meets your needs.

- Continuously monitor and adapt your choice based on technological advancements, market trends, and regulatory changes in the rare-earth metal industry.

What Types of Rare-Earth Metals Are Used in Electronics?

Neodymium and cerium are the most common rare-earth metals found in electronics. Neodymium is essential for manufacturing strong magnets used in devices such as hard disk drives, headphones, and electric motors.

Cerium is utilized in capacitors and sensors. Its catalytic properties make many electronic systems more efficient. These metals are favored for their unique properties that contribute to the performance and functionality of electronic devices.

What Types of Rare-Earth Metals Are Used in Renewable Energy?

In renewable energy applications, neodymium, dysprosium, and terbium are frequently employed. Neodymium goes into the powerful magnets used in wind turbines and electric vehicle motors. Dysprosium can be added to those magnets to improve their high-temperature performance, ensuring reliable operation in hot conditions.

Terbium colors the green phosphors for energy-efficient lighting. These rare-earth metals play vital roles in advancing renewable energy technologies, highlighting their importance in the transition to cleaner and more sustainable energy sources.

Are Rare-Earth Metals Generally More Abundant in the Earth’s Crust Compared to Precious Metals?

Yes, compared to precious metals, rare-earth metals are more common in Earth's crust. Unlike precious metals like gold, silver, and platinum, rare-earth metals are dispersed across the Earth's crust and present in greater amounts. Despite the name, rare-earth metals are quite abundant.

However, they are often dispersed and mixed with other elements, making them challenging and costly to extract in large quantities. In contrast, precious metals are typically found in concentrated deposits, which has historically made them economically attractive.

What Is the Advantage of Using Rare-Earth Metals?

The unique properties of rare earths make them indispensable in various high-tech applications. Rare-earth metals exhibit exceptional magnetic, luminescent, and catalytic properties that are crucial for manufacturing electronics, renewable energy technologies, and catalysts for chemical processes.

For example, neodymium is essential for producing the powerful magnets used in electric vehicle motors, while cerium goes into catalytic converters that reduce harmful emissions from vehicles. Additionally, rare-earth metals contribute to advancements in telecommunications, healthcare, and environmental protection.

What Is the Disadvantage of Using Rare Earth Metals?

The disadvantage of using rare-earth metals primarily stems from their challenging extraction process and environmental impact. Mining and processing them can cause significant environmental degradation, including habitat destruction, water pollution, and soil contamination. Additionally, rare-earth metals are usually found in low concentrations and dispersed forms, so it takes a lot of raw ore and energy to refine small amounts. The waste products from the refining process are often toxic.

Furthermore, geopolitical factors play a role in supply chain vulnerabilities and price volatility. A few countries dominate the extraction market. These challenges underscore the need for sustainable mining practices and diversification of rare-earth metal sources.

What Are the Key Differences in the Production Processes of Rare-Earth Metals and Ferrous Metals?

The extraction methods, refining processes, and environmental impacts of rare-earth metals differ significantly from those of ferrous metals.

Rare-earth metals are typically extracted through complex mining operations involving multiple stages of processing, including: crushing, grinding, magnetic separation, and chemical treatment to separate and concentrate the desired elements from the ore. Ores often go through solvent extraction, precipitation, and electrolysis to isolate high-purity metals. It follows that rare-earth metal extraction can generate large volumes of waste that may pollute water sources and harm natural habitats.

In contrast, ferrous metals, such as iron and steel, are mined and refined through more straightforward processes. Iron ore is commonly mined using open-pit or underground mining methods and then processed through crushing, grinding, and magnetic separation to produce iron concentrate.

The iron concentrate is further refined through smelting or direct reduction processes to obtain molten iron, which is then cast or forged as needed. While the production of ferrous metals also generates waste and emissions, modern technologies and practices are far less environmentally hazardous than those for rare earths.

What Is the Difference Between Lanthanides Metals and Rare-Earth Metals?

Lanthanide metals are a subset of rare-earth metals, encompassing the elements with atomic numbers from 57 to 71 in the periodic table. All fifteen lanthanides are considered rare earths, but the latter term also encompasses scandium and yttrium, which sit higher on the periodic table.

Another distinction is in their properties and applications. Lanthanides exhibit similar chemical and physical properties, such as high magnetic strength, luminescence, and catalytic activity, which make them valuable in various technological applications. As a slightly wider classification, rare-earth metals have a slightly broader reach into electronics, renewable energy technologies, catalysts, and other high-tech industries.

Summary

This article presented rare earth metals, explained them, and discussed their various properties and uses. To learn more about rare earth metals, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.