Video: How Will It Grow? Part 2

In this Part 2 installment of 'How Will It Grow', our Director of Applications Engineering Greg Paulsen explores key design considerations for Metal 3D Printing. Watch our new video to learn what to expect from your next DMLS project!

With Direct Metal Laser Sintering (DMLS), there are important design considerations to keep in mind to take your metal 3D Printing to the next level.

In Part 2 of our latest video, Director of Applications Engineering Greg Paulsen walks through support structures and build orientations and how they impact your part's features and surface finish.

How can you instantly optimize your metal 3D printed parts? Watch and find out!

To learn more about support structures and unsupported features, read on!

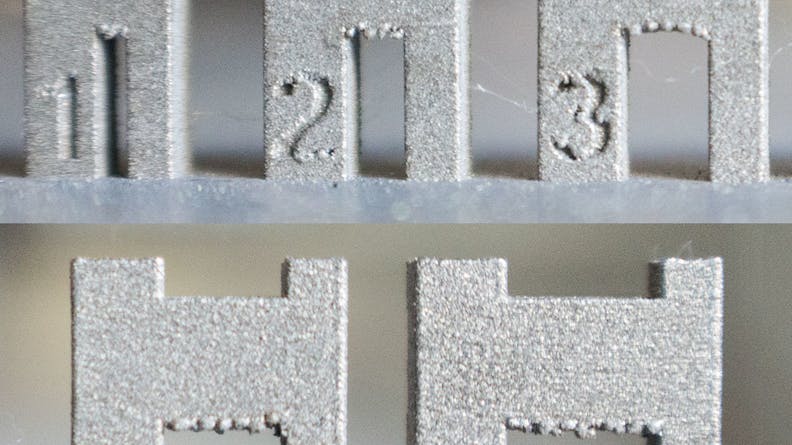

Overhang Test Angles for Natural-Grown Features

Natural-Grown Features

The key to optimizing a DMLS design and reducing its costs is to determine how a majority of it can be grown naturally without support structures. When optimizing your file for DMLS production, you will want to have an idea of the intended build orientation. Any horizontal overhangs greater than .5mm will typically require support structures, or those unsupported features could jeopardize the build. The best feature to incorporate throughout the part is the 45 degree angle where possible. This can greatly reduce the need for support structures and reduce risk during build.

Consider 45 degrees to be the Golden Rule of unsupported overhangs. Smaller angles are possible, but typically yield slightly rougher surface finishes. Build angles of less than 30 degrees are considered very risky, and have a high chance of build failure.

Unsupported Bridges in DMLS Sample Parts

Unsupported Bridges and Holes

Horizontal bridges can be grown unsupported as well. Towards the center of the bridge, you'll typically see a rougher surface finish and a more rounded surface on the horizontal portion. We recommend 2mm as the cutoff for unsupported bridges. As you can see, longer bridges are possible, but they can become problematic when subject to the stresses on larger parts.

Holes can also be naturally grown. As the size of the hole increases, the chance of it becoming egg shaped increases due to less support at the very top of the hole. Vertical holes tend to build nicely, but horizontal holes greater than 9mm diameter will require support structures to catch the overhanging layers as it closes out the top of the hole.

O-Ring Grooves

O-Ring Grooves

Each O-Ring Groove will have an area which tends to have rougher finish than the rest of the groove. Typically the down facing surface of the groove will be rougher than the other surfaces. O-Ring Grooves are possible to build, but likely require secondary machining to achieve a consistent surface finish for proper seal. The unique angle of grooves means that they will require support structures for build, or the entire part will need to be oriented in a way to minimize or eliminate the need for supports in the groove.