Xometry Product Release Notes

At Xometry, we're continuously growing and developing our platform to provide the most robust custom manufacturing experience available. See what’s new with Xometry’s products and services, all in one simple-to-navigate space.

July 2025

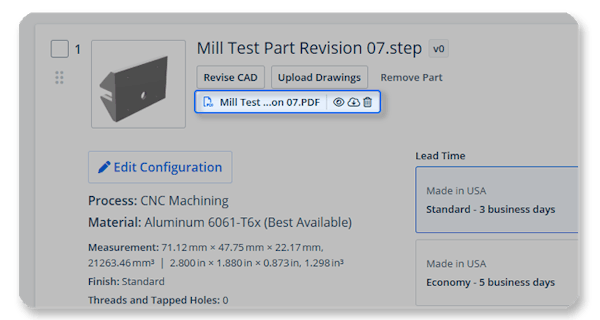

July 3rd, 2025 - Built-In PDF Viewer

A new feature is now available in our Instant Xometry Instant Quoting Engine®: a built-in PDF viewer that helps streamline your workflows! From the Quote Summary and Part Configuration pages, users can select attached PDF files to view them either in a small window or on a full screen, eliminating the need to download and view the files separately. Clicking the 'eye' symbol next to the document name will open it.

In addition, users can download or delete attached files using the corresponding buttons. Viewing drawings within the quoting experience helps streamline the quoting workflow and improves the overall experience.

June 2025

June 16th, 2025 - Updates and Additions to FDM Materials

Our menu for FDM materials has been reworked and re-categorized to make finding and choosing materials easier. Materials are now grouped by their intended use and performance characteristics: General Purpose, High Performance, Specialty, and Other.

We have also added two new material options: ABS and ASA. These generic materials are available on our global manufacturing network and provide significantly reduced pricing compared to Stratasys-branded materials. To prevent confusion, Stratasys materials have been renamed accordingly. Stratasys ABS-M30 and ASA are desirable for customers who need the most repeatability, traceability, and domestic production.

May 2025

May 15th, 2025 - New Formlabs SLA Materials

We’re happy to announce the launch of Formlabs SLA resins on Xometry’s Instant Quoting Engine®! Formlabs is a key innovator in stereolithography (SLA) 3D printing, offering a versatile portfolio of low-cost engineered materials with professional results that meet various engineering and design needs. From general prototyping to demanding functional applications, their materials empower users to create high-resolution parts with specific mechanical, thermal, and visual properties.

We launched eight key Formlabs SLA resins and plan to expand this offering further in the near future. These materials run on the Form 4 and 4L platforms to achieve consistent and repeatable results.

Materials Added:

- Formlabs Grey Resin V5

- Formlabs White Resin V5

- Formlabs Clear Resin V5

- Formlabs Tough 1500 V2

- Formlabs Tough 2000

- Formlabs Rigid 10K

- Formlabs High Temp

- Formlabs ESD

Click here to learn more about these materials.

April 2025

April 11th, 2025 - Reforcast Ship Dates Live

At Xometry, we know how crucial timely shipping is, and we usually hit the mark. But unexpected delays can happen with custom manufacturing. When they do, clear communication is key. That’s why we’ve improved how we keep you informed. If an order becomes delayed, your updated estimated ship date will now appear directly on the Orders page of the Xometry platform; look for the dates marked by a "⚠️" icon. You’ll also get an automatic email update, so you’re never left guessing.

Behind the scenes, a dedicated Xometry case manager will still be working to minimize disruptions and get your order back on track. And if you have questions, you can reach out just like always by phone or email.

April 4th, 2025 - CNC Material Explorer

Our material explorer, initially launched for sheet cutting materials, is also now available for CNC machined materials! The Material Explorer can be found under the material drop-down on the Part Configuration page during quoting. It enables users to search, filter, and view materials with an accompanying image and description, view various material properties, and navigate to articles describing the material in depth. Finding and feeling confident about picking the right material for your project has never been easier.

March 2025

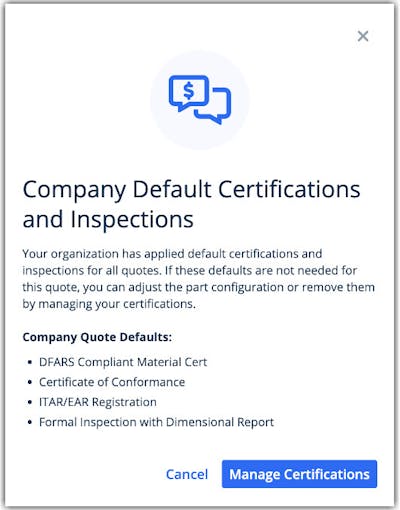

March 12th, 2025 - Teamspace Quote Presets

A new feature has been added to Xometry Teamspace; introducing quote presets! Found within the team settings page, this feature enables admins to set inspection and certification presets for quotes generated in their team.

This is especially useful for teams that adhere to company or project-specific inspection and certification requirements. Setting a quote preset will ensure team quotes have the correct requirements applied by default, resulting in fewer purchasing discrepancies and post-order corrections.

We have plans to continue expanding this feature, enabling a broader range of presets to be specified in the future, so stay tuned!

February 2025

February 13th, 2025 - International Economy for Sheet Cutting

We are excited to announce that you can now choose International Economy for your Sheet Cutting orders! Previously arranging international production and pricing for sheet cutting required manual intervention by the Xometry quoting team. Now, you have more automatic quoting options for your flat sheet-cut parts, allowing you to choose the perfect balance between cost and leadtime to fit your schedule and budget.

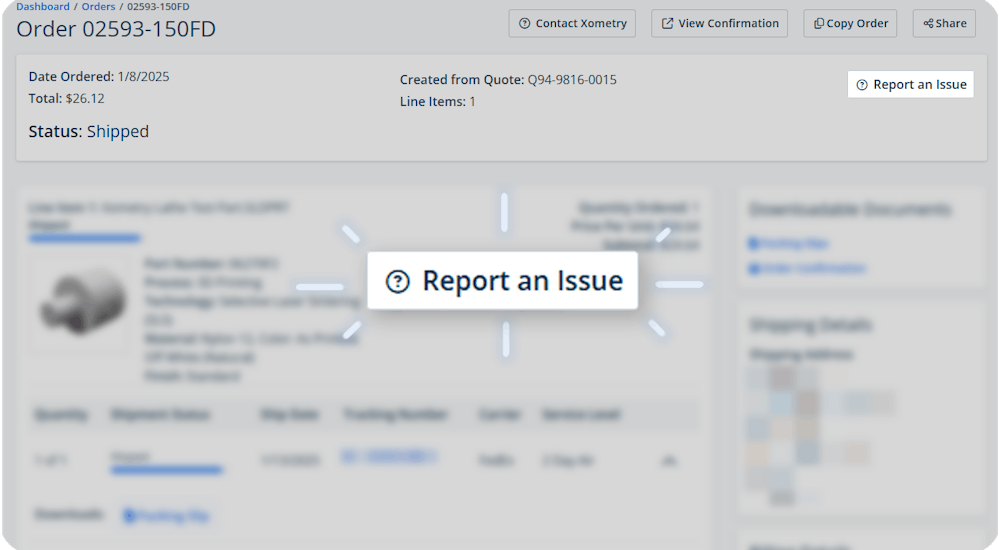

February 3rd, 2025 - Intergrated RMA Intake Form

Reporting issues with your orders is now more streamlined and easier than ever. Instead of calling or emailing, you can now submit return requests directly from your Order Summary page by clicking the 'Report An Issue' button. This will bring you to the new RMA Intake Form which ensures we have all the details needed to process your request quickly and accurately.

The primary benefits of the intake form includes:

- Simplified submission – No more wondering where to go when an issue arises.

- Complete & consistent information – The structured form ensures we receive all necessary details upfront.

- Faster resolutions – Fewer back-and-forth emails mean quicker processing times.

- Support for attachments – Easily upload photos or relevant files for a smoother review process.

- Email Confirmations – Receive an email confirmation as soon as your request is submitted.

We plan to continue expanding and improving the RMA process in the future to make the process as smooth as possible; stay tuned!

January 2025

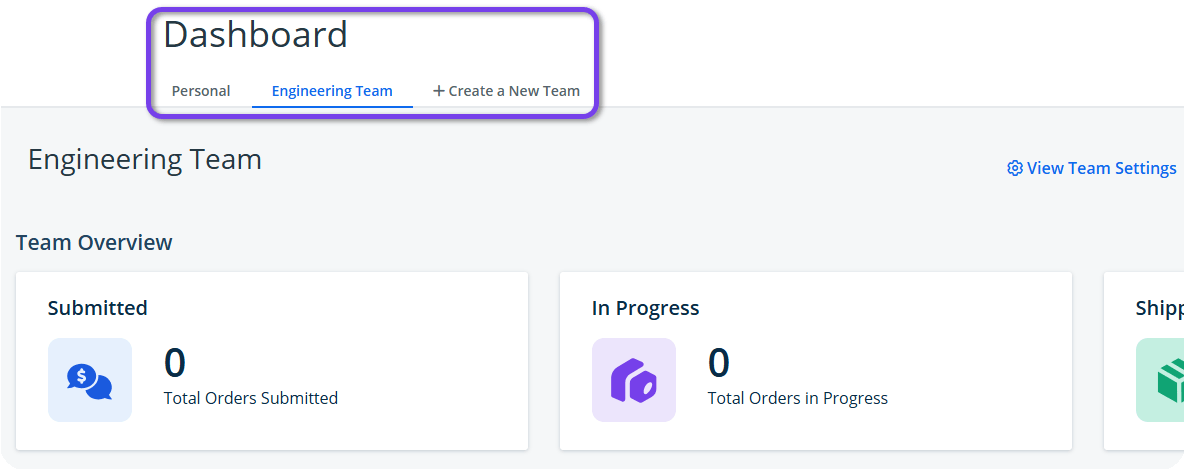

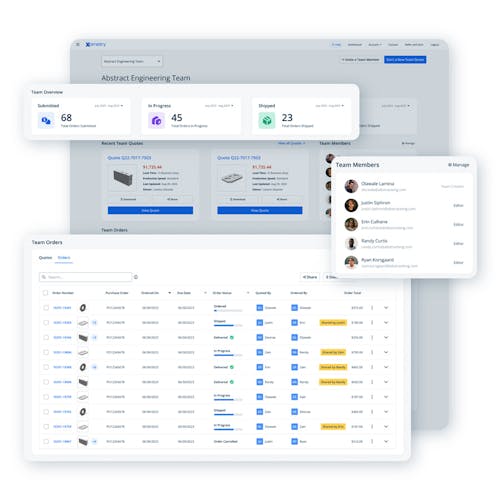

January 17th, 2025 - Teamspace Navigational Tabs

Switching between personal and team dashboards with Xometry Teamspace just got easier! Previously, users would use a dropdown selector to navigate between their dashboards. While functional, it was less intuitive than we aimed for. We removed the dropdown altogether and replaced it with navigational tabs which display personal and teamspace dashboards, allowing users to easily move between them with a single click.

In addition to the tab layout, we also made team creation easier to access thanks to the "Create a New Team" button at the top of each dashboard. This is just the first update to Teamspace we have planned for this year, keep your eyes open for further improvements!

Details:

- Removed dashboard dropdown selector menu.

- Added dashboard navigational tabs.

- Added "Create a New Team" button to dashboards.

December 2024

December 16th, 2024 - PolyShot SLS Finish

December 5th, 2024 - 🔎 Explore Materials Feature

Our Explore Materials tool is available for the Sheet Cutting process. This tool can be accessed when configuring your quote and changing materials. Click🔎Explore Materials to sort, filter, and select a material that fits your project needs.

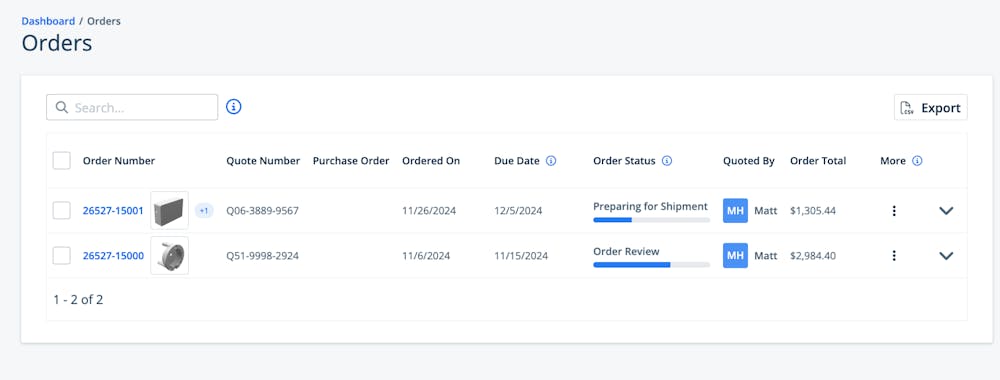

December 2nd, 2024 - In-Depth Order Statuses

Our customer post-order experience just got a big upgrade thanks to a slew of new and detailed order statuses. Previously, when checking the status of an order, users would be presented with a few statuses that broadly described the status of their order. While these statues were helpful as an overview, users voiced that they were not as in-depth as they would like.

With this update, we are addressing the feedback by expanding the number of statuses we can display to customers from 4 to 21.

Xometry customers will see the new statuses on their Personal Dashboard, Teamspace Dashboard, and Order Details Pages. Our helpdesk article explains each status in detail.

November 2024

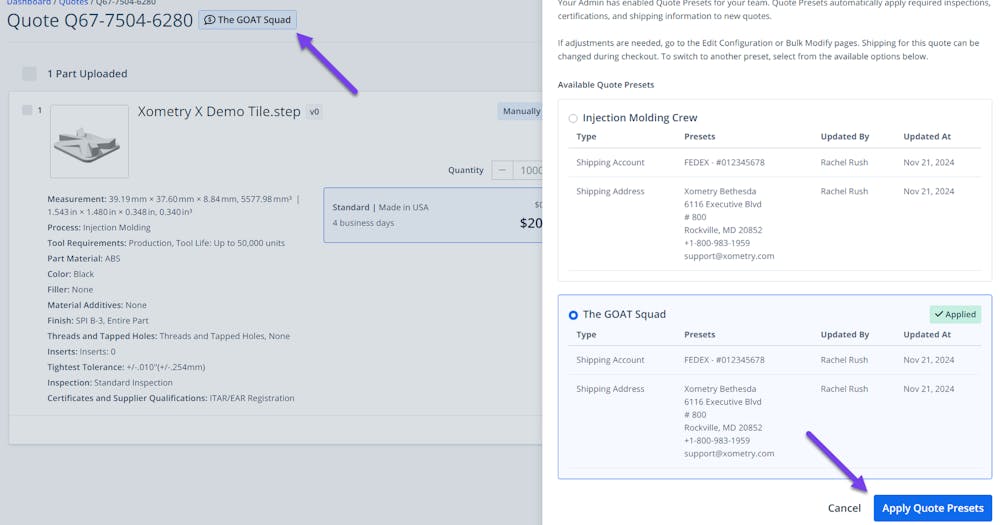

November 25th, 2024 - Teamspace Shipping Presets

We are happy to announce the launch of our newest Teamspace feature: Shipping Presets. Team Admins can now set shipping addresses, and shipping account presets for the rest of their team. When a team member checks out a new shared quote, the shipping address and shipping account will default to the team's preset.

When a preset is applied, the team name will be displayed in the upper left of the quote summary screen, next to the quote id number. Clicking the team name will open a right-side panel, which lets users select other team shipping presets if the quote happens to be shared among multiple teams.

November 19th, 2024 - Menu Update to CNC Aluminum 6061

In this update, we've reworked the Aluminum 6061 material option under our CNC machining process in the quoting menu. Previously, the material was described as "Aluminum 6061-T6". Now, we've broken out and expanded the options with the introduction of:

- Aluminum 6061-T6x (Best Available)

- Aluminum 6061-T651, Plate

- Aluminum 6061-T6/T6511, Bar/Rod

This change was made to provide customers with more granularity in one of our most popular materials and to reduce friction and confusion for our suppliers. Our "T6x (Best Available)" option is great for customers who are flexible and okay with any of the 6061-T6 tempers. When this option is chosen, our suppliers will choose the best alloy and stock shape suitable for manufacturing your part. The other new menu options allow engineers to specify exact tempers and mill forms to fit specific project requirements.

To learn more about picking between aluminum 6061-T6 alloys, check out our FAQ article.

November 4th, 2024 - International 3DP Printing Options

Continuing the trend of expanding our order options for additive manufacturing processes, we are pleased to announce that we now offer international economy pricing and lead times for select additive processes and materials! Our international economy options offer the lowest prices with the tradeoff of longer lead times. These options are available for the following process and material combinations at this time:

- FDM ASA

- FDM ULTEM 9085

- MJF Nylon 12

- SLS Nylon 12

October 2024

October 25th, 2024 - 1 Day MJF Expedited Lead Times

At Xometry, we aim to offer our customers industry-leading lead times. We are excited to announce a new expedited lead time option for our HP Multi-Jet Fusion (MJF) 3D printing process, bringing you lead times as fast as only 1 business day! This option is available for MJF Nylon 12 quotes with the standard finish selected.

If you're looking for other fast-turn 3D printing options, we offer one-day expedited lead times for SLS Nylon 12, a great alternative to MJF if you are interested in white parts.

October 1st, 2024 - Bulk Modify for Inspection Options

The Xometry product team has started work on building out the new and often requested "bulk modify" feature. The first phase of this has now been released for all users! When you select more than one line item on your quote, you will be presented with a "Bulk Modify" button. Clicking this button will lead you to the bulk modification page, which currently allows you to change inspection and certification options on multiple line items at a time.

Take note that line items are grouped by shared process in the upper left of the bulk modify screen, so you may need to apply your selections a few times depending on how many manufacturing processes are included in your quote. This is because inspection options may differ between certain processes. As mentioned, this is the first phase of this project and we look forward to expanding on this feature in the future!

Details:

- Added "Bulk Modify" button to quoting summary page when more than one line item are selected.

- Added bulk modification page.

- Added functionality for applying inspection and certification requirements across multiple line items sharing the same process.

September 2024

September 3rd, 2024 - Instant Quoting for Tube Bending and Cutting

We are excited to announce that Xometry has developed AI-driven auto quoting for our laser tube cutting and tube bending services! We enhanced our Xometry Instant Quoting Engine® with advanced geometric detection capabilities, allowing it to analyze 3D models and provide real-time pricing and lead times for these processes. This is in addition to our instant pricing for CNC machining, sheet metal, sheet cutting, 3D printing, and more.

We are the first digital marketplace to offer instant pricing and lead times for tube bending and laser tube cutting services. Utilizing the diversity of our manufacturing marketplace, we have launched our capabilities with an extensive selection of tube stock and geometries. See our updated Standard Tube Sizes page for details on the types of profiles and materials we support.

August 2024

August 16th, 2024 - Multi-factor Authentication

This update enhances account security by giving users the ability to activate multi-factor authentication (MFA) to their account. MFA helps protect your account by ensuring that even if someone has your password, they still cannot log in without access to your email. This helps keep your personal and business data secure.

You can activate MFA by logging in and visiting your Account Settings page. From there, scroll down to the "Security" section, and activate the toggle for "Email MFA".

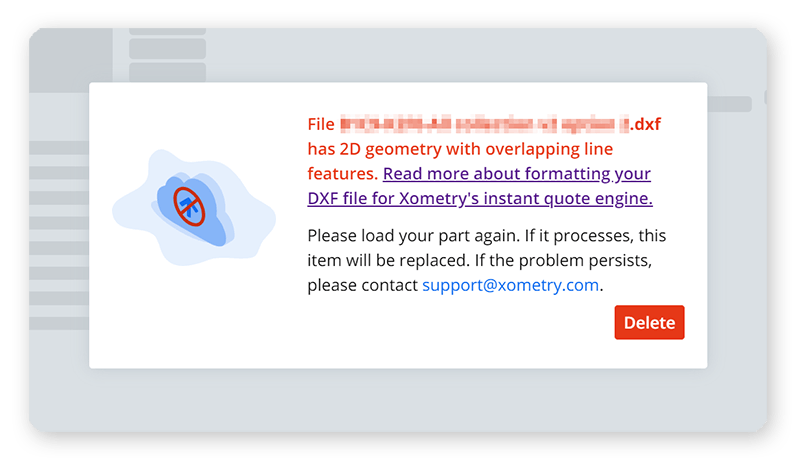

August 5th, 2024 - Improved DXF Error Messages

In this update, our UX team made improvements to the error messages that are related to 2D DXF file uploads that fail to process. Previously, the error message displayed would be generic, despite what the underlying cause was. Now, the error messages are more specific and better identify issues.

These more specific messages will help users identify areas of their files that may need to be corrected to ensure a clean file for quoting and manufacturing. If you work with DXF design files, we recommend reading our article which covers the best practices for preparing your DXF files.

July 2024

July 15th, 2024 - PDF Quote Tax and Shipping Updates

All Xometry customers can benefit from this update. If you don't know, you can generate PDF copies of your online quotes by clicking the "PDF Download" button on the upper right of the quote summary screen. Previously, tax and shipping information would only be displayed during checkout. Now, this information will be calculated and populated on the PDF quote by using the default address on the account. This generates a complete and total price.

This update may sound simple, but importantly, it improves quality of life, helps establish proper pricing expectations earlier in the buying process, and helps avoid pricing discrepancies for buyers and purchasers when submitting purchase orders.

Details:

- Added tax and shipping to downloadable PDF quotes

- Added PDF download button to checkout page

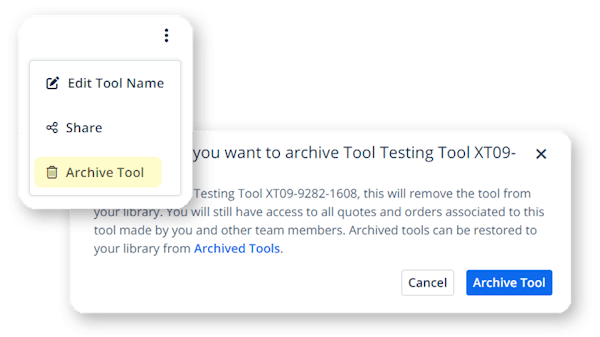

July 1st, 2024 - Archive Tools Function

We have been continuing to refine the experience and functionality for tooling line items. Users now have the ability to archive tools and hide them from their tool library by clicking the 3-dot menu next to a tool. They still have access to quotes and orders made by themselves or team members which are associated with the archived tool. Archived tools can be viewed on the new Archived Tools page, accessible through their Tool Library page. If desired, archived tools can also be restored from this page.

Details:

- Added "Archive Tool" option to 3-dot menu for tooling line items

- Added 3-dot menu to Tool Library page to access archived tools

- Created "Archived Tools" page for archived items

- Added option to restore archived tools

June 2024

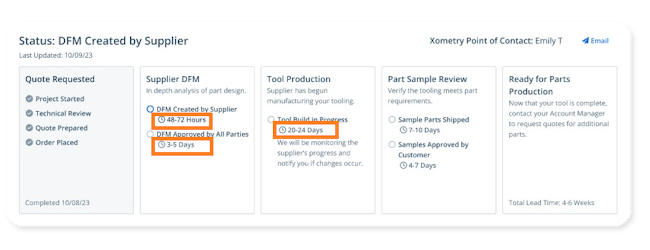

June 10th, 2024 - Tool Details Task Lead Times

The tool details page just got better! Users can now see lead times for essential tasks, such as DFM review, tool production, and more, within the tooling workflow on the Tool Details page. Xometry project managers provide these lead times, which can be updated if necessary. Customers will benefit from the enhanced transparency this update delivers, allowing them to be more knowledgeable and plan their project timelines accordingly.

In addition to task lead times, we've also improved the tool-sharing experience! You can now share tools with individuals, as well as teams created with Teamspace. Just click the "Share" button in the upper-right of the tool details page to share the tool with others.

Details:

- Added ability for Xometry staff to designate lead times for specific tasks on the Tool Details tooling workflow

- Expanded sharing functionality of tools to individual users

June 3rd, 2024 - Savable Third-Party Shipping Accounts

Users who have been granted access to third-party shipping by staff can now save shipping accounts to their accounts. This can be done either on their Account Settings page or during checkout. Supported carriers include FedEx, UPS, DHL, and USPS. This change provides a convenient and efficient way of using third-party shipping accounts, improving the user experience.

Note: If you don't currently have access to third-party shipping accounts but would like to, please contact our support staff at support@xometry.com and request that your account be approved to use one.

Details:

- "Shipping Accounts" section was added to the Account Settings page

- Added an "Add Shipping Account" button to the Account Settings and Checkout pages for approved users

- Added a "contact us" prompt to the Account Settings page for users without third-party shipping access

- Added a drop-down menu to toggle between Xometry and user shipping account options on the checkout page

May 2024

May 17th, 2024 - New Sheet Metal Tolerance Selections

Specifying tolerances for Sheet Metal parts in the Xometry Instant Quoting Engine® just got better! Configuring tolerances for sheet metal parts is now simpler and more versatile. This change helps clarify our standards and gives customers the ability to request tolerance bands greater than ± 0.010".

Details:

- Added "tighter tolerances" checkbox to tolerance selection for sheet metal parts

- Added clarification language under tolerance "Locations" for sheet metal parts

- Added Tighter than ± 0.010" as a selectable tolerance band option for sheet metal parts

- Added manual quotation trigger for sheet metal parts requiring tolerances greater than ± 0.010"

May 10th, 2024 - New Recent Quoting Activity Log

The Xometry Instant Quoting Engine® has a new feature: the Recent Activity Log! This simple but effective addition helps establish greater traceability for quoting activity. Clicking the new "Recent Activity Log" button in the upper right of a quote will open a sidebar that lists a time-stamped history of changes made to the quote. The activity log helps users track and understand changes to their quote, whether made by themselves, a team member, or Xometry staff.

Details:

- Added "Recent Activity Log" button to the Xometry Instant Quoting Engine®

- Added customer visible timestamp tracking for quote changes

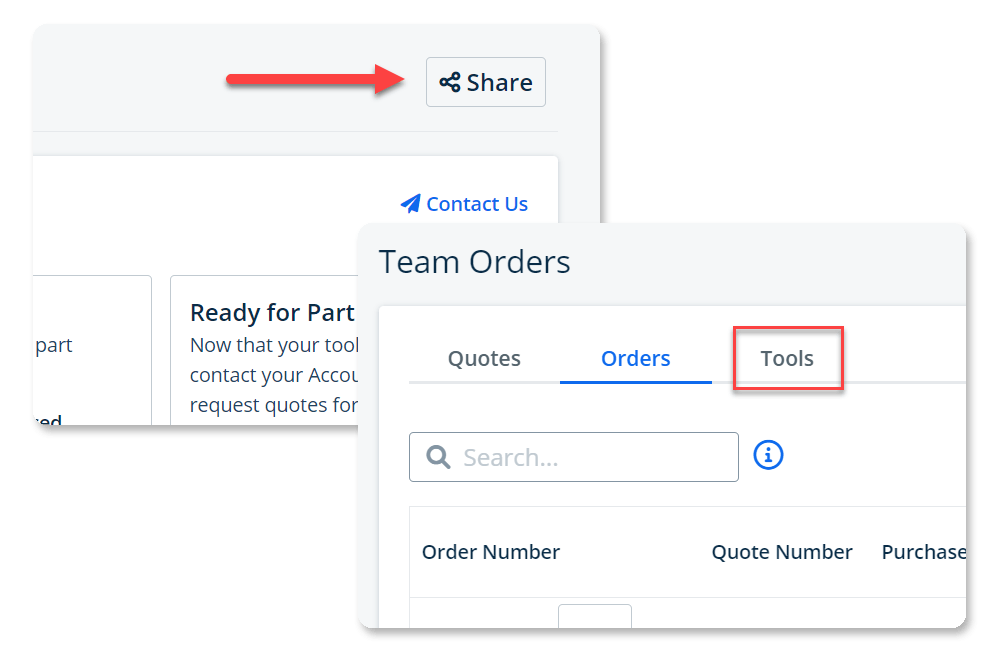

May 6th, 2024 - Teamspace Tool Sharing

Sharing tools with teams is now possible, thanks to some new updates. Tools can be shared by going to their respective tool detail page and then clicking the "Share" button in the upper right. In addition to this, shared tools are now accessible via Teamspace dashboards by clicking the "Tools" tab. When sharing a tool, all quotes and orders associated with that tool will also be automatically shared with the team.

Details:

- Added a sharing function to Tool Detail page

- Added shared Tools table to Teamspace team dashboards

May 1st, 2024 - Bulk Quote & Order Sharing

Users can now select multiple quotes or orders to share from their personal quote and order tables. While not explicitly related to Teamspace, we wanted to provide users with another method of easily populating their team dashboard with multiple quotes or orders. Instead of a user importing all of their past quotes and orders to a team dashboard, this feature lets users select specific quotes and orders to share en masse.

Details:

- Added check boxes to user Quote and Order history pages

- Added "Share" button to user Quote and Order history pages

April 2024

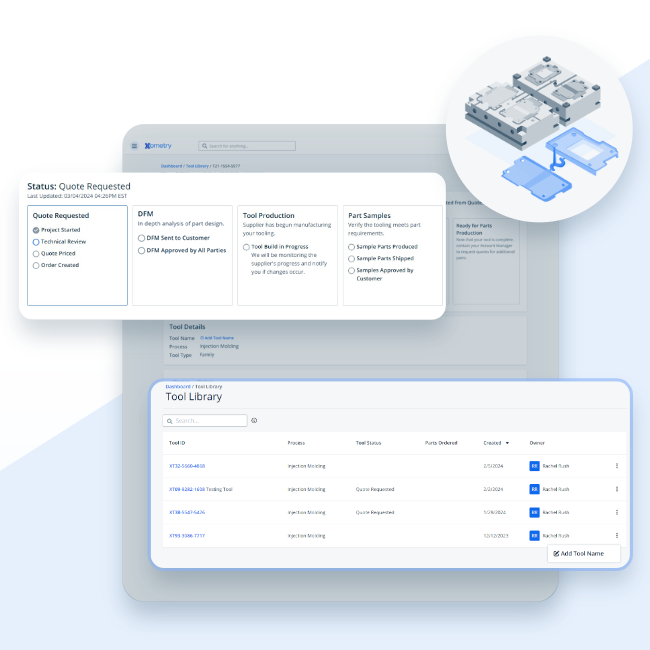

April 9th, 2024 - Tool Library & Tool Detail Pages Added

Our product team has been working hard to create two new pages to give customers unprecedented visibility into their tooled process orders. Introducing the "Tool Library" and "Tool Detail" pages.

You can now easily access all your tooling line items across related quotes and orders in one space. Use the search bar to find a specific tool or give them a custom name for ease of management. Clicking on a "Tool ID" number will open its Tool Detail page, giving you a wealth of information and transparency into your project. Get a detailed status update of where your tooling quote or order is in the process, easily find your best point of contact, and use the page to track important milestones and T1 sample ship dates. Learn more about how it works by clicking here.

Details:

- Added "Tool Library" to user account navigation menus

- Added ability to search for quoted and ordered tooling line items

- Added the ability to add name tools

- Added "Tool Detail" view when clicking into a tool from the library

- Added milestone progress tracker for tool production

- Added point of contact field

- Tooling line items can now be designated as "Single Part" or "Family Tool"

- Parts associated with a tool will now be listed under the detail view with a corresponding quantity matching production quantities across related orders

March 2024

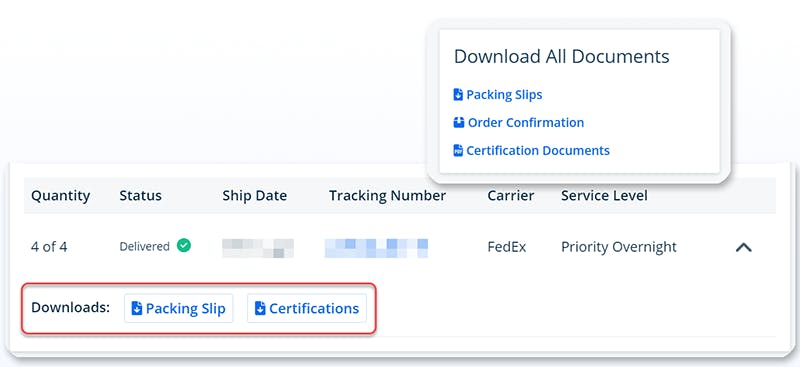

March 1, 2024 - Documentation Download on Order Details Page

Users can now access and download order-related documentation via the order detail page. This allows users to more easily manage their orders effectively by having easy access to the documents they need, including packing slips, order confirmation, certifications, and inspection reports. Documents can be downloaded via the new "Download All Documents" panel to the right of the page, or by expanding line items and downloading the corresponding items. Previously these documents had to be manually requested and fulfilled by Xometry's staff, which was time-consuming.

Details:

- Added document download panel to right side of Order Detail pages

- Added "Downloads" and corresponding document download buttons to expandable line item details

- Added download options for certifications, inspection reports, packing slips and more

February 2024

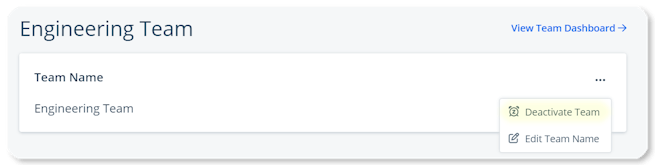

February 23, 2024 - Teamspace Activity Log & Team Deactivation

Teamspace Users can now deactivate teams that are no longer required directly from Team Settings. This feature allows Users to streamline their workspace by removing clutter without permanently losing any data. Users can also stay more informed with the new activity log in Team Settings. This log provides visibility into team dynamics, showing when members join or leave and tracking invite receptions.

Details:

- Added "Deactivate Team" option to the 3-dot menu on the Team Settings page.

- Added confirmation prompt for team deactivation.

- Added "Event Log" tab under the team member management section on the Team Settings page.

February 5, 2024 - Repeat Part Toggle Added to Quoting Interface

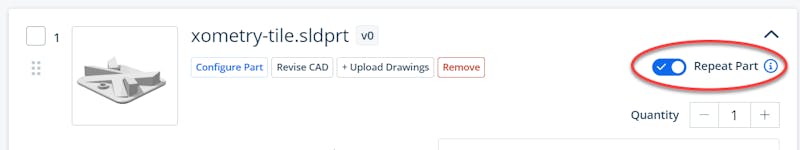

As you configure your quote within the Xometry Instant Quoting Engine®, you can now tag line items as repeat work. This is done by simply activating the "Repeat Part" toggle to the upper right of the line item panel on the quote summary screen, as shown below:

This is a simple and effective way of communicating to Xometry that you have ordered the part before. Be sure to have this toggle selected for repeat work, as it will trickle down into our backend systems and increase the efficiency of processing your repeat order. Additionally, it can be helpful to provide us with related quotes, order numbers, or purchase orders in the notes section. This toggle will be automatically selected when creating a quote via the "Copy Order" function or when our system identifies a part as previously ordered.

To learn more about setting up repeat work and orders, check out our FAQ article.

January 2024

January 12, 2024 - Teamspace Notifications & New Functionalities

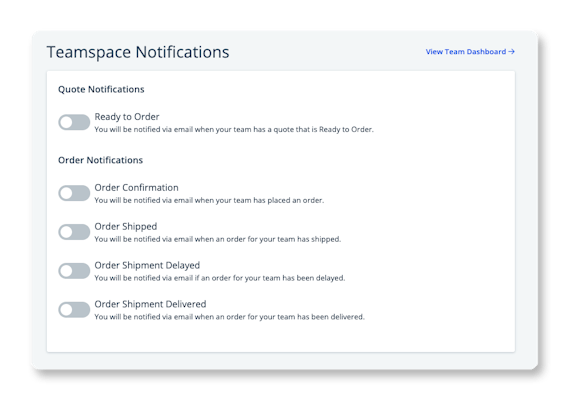

Our product team has been working on implementing additional improvements and functionality to the Xometry Teamspace experience. The first batch of these updates has arrived with the new email notification settings that can be found on your "Team Settings" page.

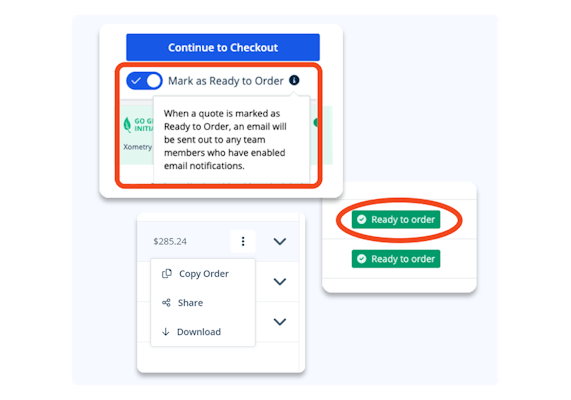

A "Mark as Ready to Order" toggle has also been added to the quoting screen interface that marks quotes accordingly in the team's quotes table. This feature streamlines the ordering process, ensuring timely and efficient procurement by clearly signaling when quotes are finalized and ready for purchase and providing users with more visibility into their project development.

Finally, users can now download a document package for orders by clicking on the three-dot menu on the team orders table, and then selecting "Download". Documents will include items such as packing lists and invoices.

Details:

- Added "Teamspace Notifications" options to the "Team Settings" page giving users email notification toggles for:

- When quotes are marked "Ready to Order"

- When team members have placed an order

- When an order shared with the team has been shipped

- When an order shared with the team experiences a delay

- When an order shared with the team has been delivered

- Added "Mark as Ready to Order" toggle under the checkout button on the quoting screen

- Added visual indicator for "Ready to Order" quotes on the team Quotes table

- Added "Download" option under the three-dot (...) menu on the team Orders table allowing users to download a document package related to the selected order

December 2023

December 5, 2023 - Quote History Table UX/UI Improvements

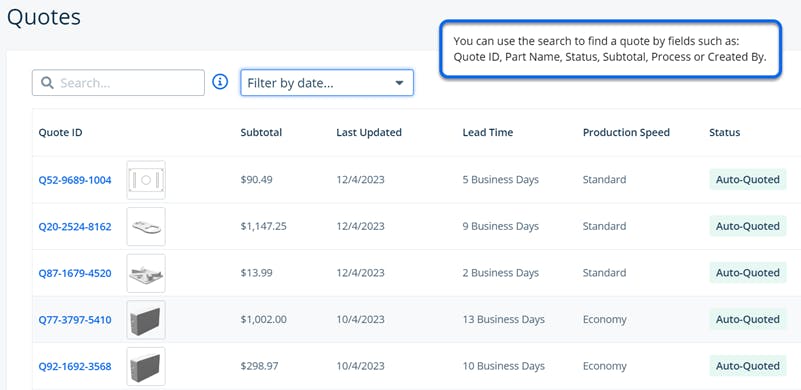

The user interface of the quotes history table has been updated for better and more consistent functionality between pages. We wanted to give users a consistent experience between their Order History and their Quote History. Prior to this launch, the styling and capabilities of the two differed. The capabilities have been enhanced to match what can be found in the Xometry Teamspace experience. This includes search functionality for Quote ID, Part Name, Status, Subtotal, Process, and Quote Creator.

Details:

- Updated the user interface of the quote history page to match the Order history page

- Added search functionality (Quote ID, Part Names, Processes, Quote Creator, etc.)

- Added "Filter by date" functionality to filter results by date range

November 2023

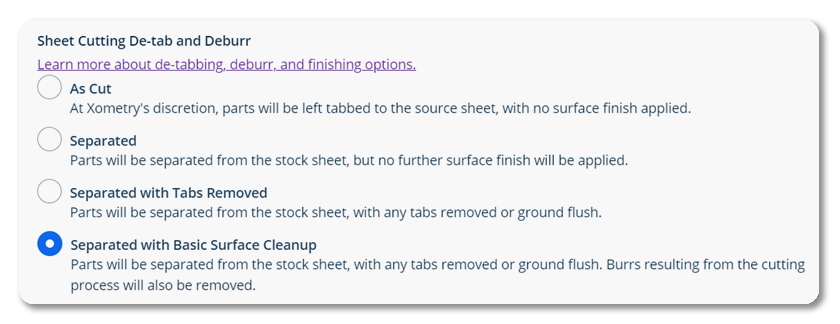

November 17, 2023 - New Sheet Cutting De-tab & Deburring Options

The way you can receive your Sheet Cut parts has been expanded with three new options! Regarding sheet parts, Xometry set a quality standard involving removing vestigial tabs, deburring, and surface cleanup by default. While many customers appreciated the effort, it did result in more work being done, which led to higher pricing compared to not doing those steps. Now, customers have several new part processing options to choose from, allowing them to cut costs on their sheet-cut parts.

These additional choices allow customers to precisely control the level of processing their cut sheet parts receive, from leaving the parts tabbed to the source sheet to the same level of cleanup Xometry has maintained. You can learn more about each option in detail in our FAQ article.

Details:

- Added a "De-tab and Deburr" section to the part configuration page in the Xometry Instant Quoting Engine®

- Added "As Cut," "Separated," "Separated with Tabs Removed," and "Separated with Basic Surface Cleanup" to the sheet cutting menu

- Added logic for when post-processing finishes (e.g., Anodize) are applied, the selection is locked and defaulted to "Separated with Basic Surface Cleanup"

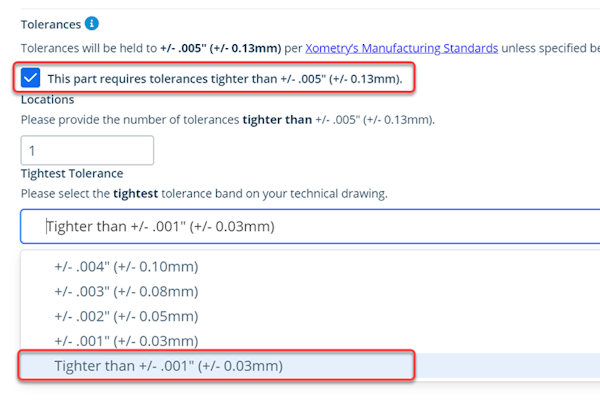

November 10, 2023 - Tighter CNC Tolerance Selection and Menu

We've made some adjustments to how CNC tolerances are applied within the Xometry Instant Quoting Engine. This update helps remove ambiguity, clarifies our standards, and introduces a new choice for customers looking for tolerances tighter than +/- 0.001".

Details:

- Added "tighter tolerances" checkbox to CNC tolerance section within the quoting menu

- Added clarification language under "Locations"

- Added Tighter than +/- 0.001" as a selectable tolerance band option

- Added manual quotation trigger for parts requiring greater than +/- 0.001" tolerances

October 2023

October 26, 2023 - Domestic AS9100 Orders are Now Auto-Quotable

Aerospace engineers can now receive instant pricing for USA-made, AS9100-certified parts. Upload your CAD file, configure your part, and select "AS9100 Certified" from the "Certificates and Supplier Qualifications" options. This builds upon our update in September, which added AS9100 to the menu; however, now pricing updates in real-time instead of requiring manual intervention.

Details:

- Selecting "AS9100 Certified" no longer triggers the manual-quotation workflow.

- Updated pricing logic for AS9100 Certified orders to enable automatic quoting.

October 24, 2023 - Launch of Xometry Teamspace

We are proud to add a new product to Xometry's offerings: Teamspace! We've learned that customers yearned for more collaboration tools within our platform, and Teamspace is here to answer that call. Teamspace is a collaborative workspace within your Xometry account that gives you and your team members quick and easy access to quotes, order placement, part statuses, tracking information, and more.

Use Teamspace to share quote and order details, execute team orders, check line item statuses on open orders, find shipment tracking numbers, and more! Best of all, this update is free to use; all you need to do is log in to your Xometry account to get started. Visit our Teamspace page to learn more.

September 2023

September 14, 2023 - Additional RFQ Options Added to Homepage

The quoting experience from the Xometry website homepage has been updated. In addition to quickly starting an instant quote from the homepage, visitors can now start RFQs for "High-Volume Production" and "Full Product Lifecycle" projects. The new tab interface of the quoting module allows easy access to these quoting options.

September 14, 2023 - "AS9100 Certified" Added to Selectable Certifications

Calling out orders that require AS9100 certification is now easier than ever before. Users can now find "AS9100 Certified" as an option under the "Certificates and Supplier Qualifications" section when configuring and quoting their parts. At this time, a manual quotation will be required to finalize quotes requiring AS9100 certification.

Details:

- Gave users the ability to select "AS9100 Certified" when configuring a quote.

- Added trigger for manual quotation required when "AS9100 Certified" is selected.

September 13, 2023 - Update to Website Navigation Bar

Our web development team added a new element to the navigation menu for a better user experience. Now, when visiting Xometry's website, visitors will have a "Sign In" button in the upper right corner of the page. When a user is signed into the website, a drop-down menu with their account name will be displayed instead.

Logged-in users can use the drop-down menu to navigate to their quotes, orders, Workcenter (for suppliers), account settings, and more. Providing quicker and easier access to these account-specific pages will result in a smoother experience.

Details:

- Gave users the ability to sign in to their accounts from anywhere on www.xometry.com

- Gave signed-in users the ability to navigate directly to the following pages from anywhere on www.xometry.com :

- User dashboard

- Workcenter (supplier only)

- Quotes page

- Orders page

- Parts library page

- Account settings

- Referral page

July 2023

July 6th, 2023 - Enhanced Visibility for Account Defaults

Our product team has launched an initiative to help our corporate users stay informed about account-level quoting defaults. Previously when default certification and inspection options were enabled for a user, visibility was limited. Now these default settings are more visible thanks to UI updates to the Xometry Instant Quoting Engine®.

The defaults typically apply to all quotes created by/on behalf of the accounts’ users. In cases when the quotes don’t need those defaults, customers can benefit from lower prices and faster lead times.

Users can now:

- View their account defaults, including Certifications and Inspections, on their Quote Summary Page.

- Learn more about what settings and why have been applied to their quote.

- Easily customize their quote and discover how defaults impact the cost and timeline of their project.

Note: Account defaults are only visible to users who have had them enabled. If you are interested in company defaults, please get in touch with your account representative.

May 2023

May 25th, 2023 - New 3D Printing Process: Nexa3D LSPc®

We are excited to announce that we are now offering Nexa3D's Lubricant Sublayer Photo-curing (LSPc®) technology in the Xometry Instant Quoting Engine®! This new process addition marks our 9th unique additive manufacturing technology we provide with automatic quoting. Along with LSPc® comes a dozen new photopolymer resins ranging from end-use rigid composites, rubber-like elastomers, and specialty options.

![]()

Check out the new additions by starting a new quote and selecting "Nexa3D Lubricant Sublayer Photo-curing (LSPc)" under our plastic 3D printing menu options, or learn more about the process.

Details:

- Added "Nexa3D Lubricant Sublayer Photo-curing (LSPc)" manufacturing process to plastic 3D printing technologies

- Added sub-categories "Thermoplastic" and "Resin (Photopolymer)"

- Added 12 materials under LSPc:

- General Purpose: xABS3843 , x45, xPRO410

- Translucent / Clear: xMODEL17 Clear

- Engineering Resins: xCE, xESD (Static Dissipative) xPP405, xPEEK147

- Rubber-Like: xFLEX402 (Shore A 73), xFLEX475 (Shore A 44)

- Ceramic-Filled Composite: xCERAMIC3280

May 23th, 2023 - Domestic Economy Lead Time Option

We're giving customers more flexibility with pricing and lead times thanks to a new option to choose from; Domestic Economy. This is a great choice for users who want or need to keep their products produced within the United States but are also looking for the lowest pricing when they can afford some extra time on their project. Now, you can potentially have up to four different lead-time and pricing tiers to choose from, ranging from international production to domestic expedites. Note that available lead-time options vary depending on the chosen manufacturing process.

May 12th, 2023 - Auto-Quote Parts Containing Inserts

We are pleased to announce the release of a new feature for the Xometry Instant Quoting Engine®; auto-quotable parts with embedded inserts! We were excited to implement this highly requested feature, which allows users to get auto-quotes on CNC, sheet metal, and sheet cut parts embedded with standard inserts. Previously multi-body files would be flagged as an assembly which prompts a manual quotation, and the embedded inserts would need to be manually removed before uploading to get instant pricing and lead times.

Now when a user uploads such a file, they will see a prompt and follow a few simple steps that allow them to identify the part (e.g., the main part) in their file to be quoted, unlocking instant quoting once completed. This update also sets the framework that will allow us to further improve the quoting process for assemblies in the future.

Details:

- Implemented new functionality which automatically detects when multi-part files are uploaded

- Added a user prompt that allows users to specify the individual part they would like to quote on multi-part files for an instant quote

- In instances where users want to request a quote for an assembly file, they can dismiss the prompt or select "quote entire assembly" to request a manual quote review of their assembly file

- Implemented interactive 3D viewer for selecting parts within an assembly file, including functions such as "explode" allowing users to find and select specific parts easily

- Added ability for users to name selected parts of an assembly

- This functionality is available for CNC machining, sheet metal, and sheet cutting parts for this initial release

May 5th, 2023 - Additional Sheet Cut Rubber Durometers Added

The Xometry Instant Quoting Engine® now has more selectable durometers for our rubber materials when manufacturing with our sheet-cutting process. This update gives users more hardness options and helps prevent mixups during manufacturing.

Details:

- Buna-N Rubber, Adhesive Backed Additions

- Shore A 50

- Buna-N Rubber Additions

- Shore A 40

- Shore A 50

- High temp Silicone Rubber, Adhesive-Backed Additions

- Shore A 40

- Shore A 50

- Shore A 60

- Shore A 70

- High Temp Silicone Rubber Additions

- Shore A 40

- Shore A 50

- Shore A 60

- Shore A 70

April 2023

April 20th, 2023 - Additional Sheet Cutting Options Added

We've further expanded the Xometry Instant Quoting Engine® with more material options for our sheet-cutting service. This update adds options across various categories, including metal, composite, and rubber materials.

Details:

-Added the following metal sheet-cut materials:

- Aluminum 2024-T3 with Gauges: 0.02", 0.032", 0.04", 0.05", 0.063", 0.071", 0.08", 0.09", 0.1", 0.125", 0.19", 0.25"

- Stainless Steel 301 Annealed, Quarter Hard, and Half Hard, Full Hard with Gauges: 0.02", 0.04", 0.032", 0.05", 0.062"

-Added the following composite sheet-cut materials:

- Garolite G10/FR4, Yellow with Gauges: 0.0625", 0.125", 0.25", 0.375"

-Added the following rubber sheet-cut materials:

- Neoprene, Smooth, Black with Gauges: 0.03125", 0.0625", 0.094", 0.125", 0.188", 0.25", 0.375", 0.5"

- Includes durometers of: 30A, 40A, 50A, 60A, 70A

April 19th, 2023 - Shipping Address Auto Completion

A small but significant change has been made to our checkout experience. When entering a new US shipping address, it will automatically show addresses that match the USPS database. Users can select their address from the matches to autocomplete their shipping address. This change will help prevent wrong addresses from being provided, such as when a typo occurs, which could lead to downstream shipment and delivery issues. Address validation is currently available for US-based addresses only.

April 6th, 2023 - Multiple Price Tiers and Lead Times for Manual Quotes

The Xometry Instant Quoting Engine® provides instant and automatic quoting for a diverse and wide range of manufacturing processes and specifications; however, some projects have special requirements, such as custom materials, finishes, and other needs, which require a manual quotation from our quoting staff. In this update, we've worked to improve the manual quotation experience for our customers. There is now better visibility into manual quote requests. From their quoting dashboard, customers can easily see which quotes were submitted for manual review and which are ready for purchase.

Additionally, we added the ability for customers to choose from multiple pricing and lead time options for manually quoted projects right within the quote summary page. Overall we believe this update will improve the user experience, lead to more efficient transactions and help alleviate some operational and purchasing burdens for all parties regarding manually quoted projects.

Details:

- Updated customer dashboards to allow visibility into requests that have been submitted for manual review

- Added ability to list multiple price and lead time tiers on the quote summary page

- Added ability for customers to select their desired price and lead time option on the quote page

- Added functionality allowing customers to download PDF copies of each manually quoted price tier option

March 2023

March 23, 2023 - Auto-quoting Available for Multiple Finishes

Pricing will now automatically quote for parts with more than one finish applied. This has been a long-requested feature that we are excited to implement! Previously, when multiple finishes were specified, quotes would require manual intervention from Xometry staff to finalize pricing. Now users can do things like call out anodizing and chem-film on the same part, and the quoted pricing will automatically update.

Details:

- Added auto-quoting functionality for parts with multiple finishes

March 16, 2023 - Support for SOLIDWORKS 2023 Files Added

An update was released to our backend geometry analysis which enables us to support SLDPRT files from SOLIDWORKS 2023. Customers who use SOLIDWORKS 2023 can now upload their 2023 files directly to the Xometry Instant Quoting Engine® for an instant quote.

March 10, 2023 - New Bendable Sheet Metal Materials Added

The material menu for our sheet metal fabrication service has been expanded with an array of new options to choose from! The majority of these additions will automatically quote in the Xometry Instant Quoting Engine®, allowing users to quickly get sheet metal quotes in even more materials.

Details:

-Added 16 new auto-quotable options to the sheet metal materials menu

- 1095 Spring Steel

- A653 Galvanized *

- AZ55 Galvalume *

- Aluminum 1100-H14

- Copper 110, H02

- Hot Rolled Steel 1045

- Hot Rolled Steel A569/ASTM A1011

- Nickel Alloy 200

- Nickel Alloy 400

- Stainless Steel 304 #4 brushed

- Stainless Steel 304, #8 mirror polish

- Stainless Steel 316, #4 brushed

- Steel 1018

- Steel A36

- Steel A36, pickled and oiled *

- Steel A366/1008

Materials marked with an asterisk (*) will require manual quoting when combined with a post-process finishing option.

-Added 4 new materials available for manual quoting

- Brass 260

- Titanium (Grade 2)

- Titanium 6AI-4V (Grade 5)

- Inconel 625

March 1, 2023 - Powder Coating Options Added

We have updated how powder coating is specified within the Xometry Instant Quoting Engine®. After users select "Powder Coating" as a finishing option, new drop-down menus will appear, allowing them to customize the exact color and sheen. Please view the entire list of powder-coating finishes we offer in our photo gallery.

Details:

-Added drop-down menu for color selection under the powder coating finish option

-Added drop-down menu for sheen selection under the powder coating finish option

-Added an "Other" color option with a write-in field to specify unlisted paints or colors

February 2023

February 13, 2023 - Additional Sheet Cutting Materials

By popular demand, we have added galvanized steel and additional stainless steel materials to our sheet-cutting materials menu. Previously these options would require a custom manual quote to accommodate, but thanks to this update, they will now all automatically quote, reducing hassle and time for users.

Details:

-Added galvanized steel options for sheet-cutting materials

- A653 Galvanized Steel

- A653 Galvanneal Steel

-Added additional stainless steel sheet-cutting materials

- Stainless Steel 304, #4 Brushed

- Stainless Steel 304, #8 Mirror Polish

- Stainless Steel 316, #4 Brushed

February 6, 2023 - Request A Quote Tool

Built-in “Request A Quote” functionality added:

Users now have the option to upload RFQ packages directly to the Xometry Instant Quoting Engine®. You can securely upload and send a quote request to our team in a few simple steps. Our direct RFQ request is excellent for buyers and procurement leads with large data packages that need to be quoted.

Details:

-Updated customer quoting dashboard UI to accommodate “Request A Quote” functionality

- The file upload section on the user’s dashboard page has been divided into two sections

- Added “Request A Quote” button to the right side of the file upload section

- Clicking “Request A Quote” triggers a new pop-up quoting modal

- Added ability to upload any file type while in the ”Request A Quote” quoting modal

- Added user experience elements to help guide users through the RFQ process

February 3, 2023 - More Options for CNC Plastics and Composites

Additional CNC Plastics and Composites:

We have expanded our selection of plastic and composite materials for CNC machining. Additionally, each now has applicable color options to choose from. This will give customers greater customizability and help reduce ambiguity for suppliers.

Details:

- Added a color drop-down menu for all CNC plastic and composite materials

- Expanded color options for certain CNC plastic and composite materials

- Added new composite material options

- Garolite G10 (FR4)

- Garolite G11 (FR5)

- Acetal (Delrin) has been separated into new variant selections

- Acetal

- Delrin 150

- Delrin 100

- Added new plastic material options

- PEEK (USP Class VI TECAPEEK)

- PEEK GF30

- ULTEM 2300

January 2023

January 31, 2023 - New Order Summary Page

New order summary page:

The order summary page has been revamped for an improved user experience. The changes allow customers to easily check their order history and current order statuses at a glance.

Details:

- UI has been updated to align with the website aesthetic

- Added sort-by function

- Added order status tracker column

- Added ”Next Estimated Ship Date” column

January 26, 2023 - CNC Tool Steels and ULTEM

New CNC materials added:

More auto-quotable CNC materials have been added, allowing customers to quote tool steels and ULTEM 1000 quickly.

Details:

- CNC material options for tool steels have been added to the list of steel options

- Added ”Tool Steel A2”

- Added ”Tool Steel O1”

- ”ULTEM 1000” added to the list of plastic materials for CNC machining

January 24, 2023 - Quick Turn Injection Molding Added

New quick turn injection molding capability:

Our injection molding offering has been expanded with our new Quick Turn Molding service. Customers can take advantage of this service directly within the quoting engine and get injection molded parts more quickly than ever before possible.

Details:

- Menu options added to our injection molding process in the quoting engine

- Added ”Quick-Turn Prototype” to the list of tooling options

- Quick turn molding material and color options added for the ”Quick-Turn Prototype” selection

- ”Light Texture” and ”Heavy Texture” options were added under the ”Quick-Turn Prototype” finishes

January 20, 2023 - New CNC Stainless Steel Options

New stainless steel CNC materials added:

We’ve expanded our auto-quotable stainless steel offerings for CNC machining. We also added a cost-saving option for 300 series stainless steel for customers who do not have specific grade preferences.

Details:

- ”Stainless Steel Any 300-Series” added to the list of stainless steel material options for CNC machining

- Lower cost compared to other 300 series stainless steel options

- Parts with this selection will be made from any 300-series stainless steel (e.g., SS303, SS304, SS316, etc.)

- Added 17-4PH and 15-5PH stainless steel in multiple temper options for CNC machining

- Added ”Stainless Steel 17-4PH H1150”

- Added ”Stainless Steel 17-4PH H900”

- Added ”Stainless Steel 15-5PH H1150”

- Added ”Stainless Steel 15-5PH H900”

January 13, 2023 - PolyJet Updates

Updates to our PolyJet 3D printing service:

To accommodate the latest generation of Stratasys PolyJet 3D printers, we added and implemented some changes to our menu options when quoting for PolyJet. These additions and changes allow customers to easily access full-color 3D printing, new PolyJet materials, and a greater range of customization options for their PolyJet prints.

Details:

- Added new PolyJet material menu options and updated existing naming conventions

- “Rigid Photopolymer” changed to “Opaque Photopolymer, Rigid”

- “Rubber-like Photopolymer” changed to “Photopolymer, Rubber-like”

- “Multi-material” changed to “Multi Material, Digital Overmold”

- Added “Translucent, Clear Photopolymer” as a material option

- Added “Multi-Color, CAD Defined” as a material option, allowing customers to easily quote and order full-color prints with compatible files (e.g., 3MF)

- Added “Digital ABS Plus” as a material option

- Hardness selections for rubber-like material have been simplified (e.g., ”Shore A 45-50” is now ”Shore A 50”)

- Added new material color options

- Cyan, magenta, and yellow are now available color choices for the ”Opaque Photopolymer, Rigid” material

- ”Other” is now available as a color option for rubber-like and rigid materials, allowing customers to define custom colors for these materials