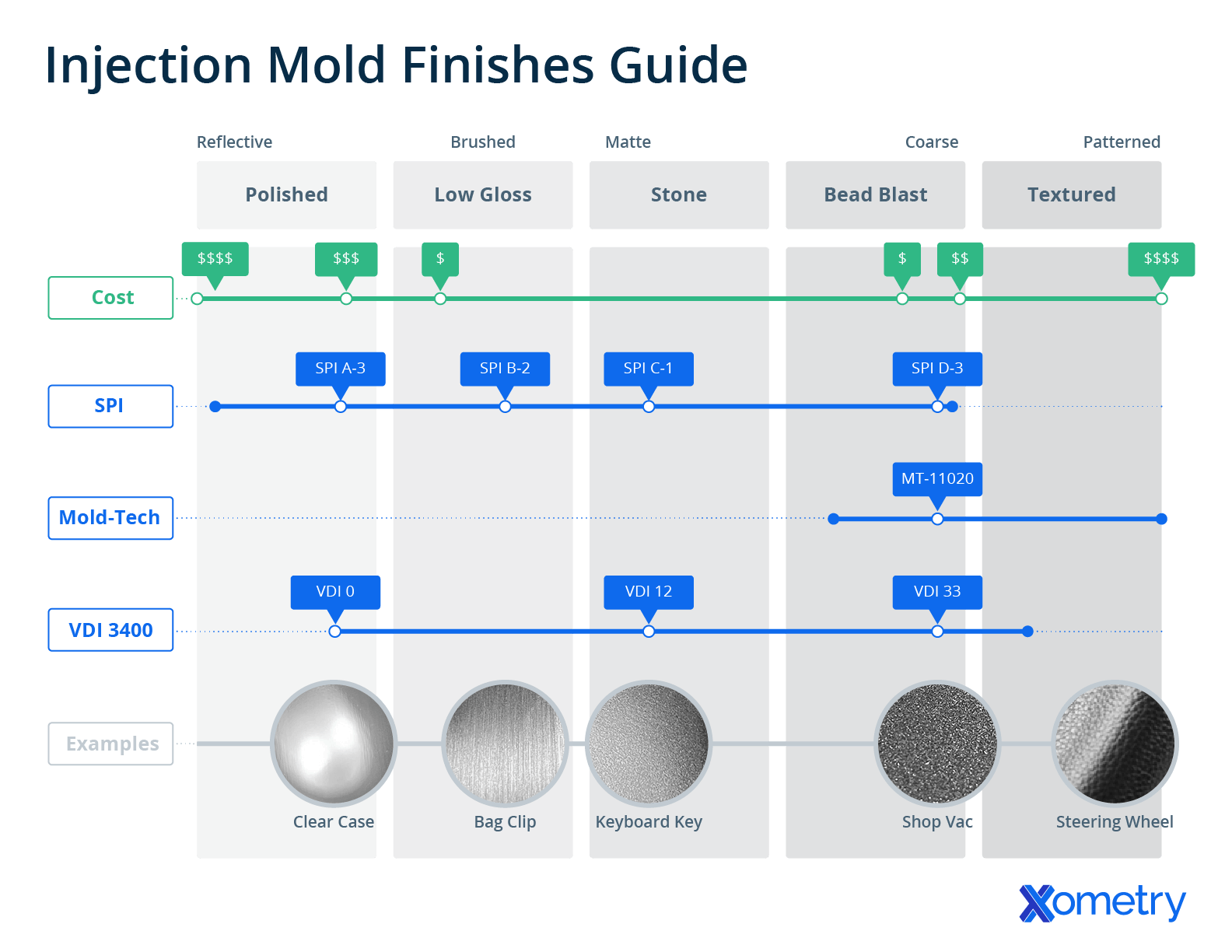

A common question we hear at Xometry is, "What do your molded parts look like?" The answer is: however you want it! Xometry has access to a diverse marketplace of molding suppliers and all standard mold finishing options. Our mold finishes include SPI, MoldTech, VDI (EDM), and others. Mold finishes can range from glossy to matte to even patterned. Finishes applied to the surface of the mold cavity transfer to the surface of the molded part. For example, a mold surface that is polished to be reflective will make a reflective (or transparent) part. Mold finishes are different from finishes for CNC machined, or 3D printed parts, where each component is treated individually. Adding a finish or texture can change the tool's price depending on the process required, but it does not alter the price of the individual parts.

The most common finishes used include those from the Society of the Plastics Industry (SPI), which are a set of standard mold finishes starting from heavily polished (SPI A) to semi-gloss (SPI B) to fine and coarse matte (SPI C and SPI D). Where polished textures can increase a parts' cosmetic reflection or transparency on transparent polymers, matte finishes can help provide more subdued tones and even help prevent fingerprints on handled products (e.g., your laptop's frame and keyboard).

Injection molded finishes guide: SPI, Mold-Tech, and VDI 3400

Get your Free Xometry Injection Molding Finishes Card

Society of Plastics Industry (SPI) Mold Finishes

| SPI Finish | Description | Typical Applications | Surface Roughness (Ra µm) |

|---|---|---|---|

SPI Finish SPI A-1 | Description Grade #3, 6000 Grit Diamond Buff | Typical Applications High polish or transparent parts, optically clear | Surface Roughness (Ra µm) 0.012 - 0.025 |

SPI Finish SPI A-2 | Description Grade #6, 3000 Grit Diamond Buff | Typical Applications High polish or transparent parts | Surface Roughness (Ra µm) 0.025 - 0.050 |

SPI Finish SPI A-3 | Description Grade #15, 1200 Grit Diamond Buff | Typical Applications High-to-medium polish parts, non-optical lenses | Surface Roughness (Ra µm) 0.050 - 0.100 |

SPI Finish SPI B-1 | Description 600 Grit Paper | Typical Applications Medium polish parts | Surface Roughness (Ra µm) 0.05 - 0.10 |

SPI Finish SPI B-2 | Description 400 Grit Paper | Typical Applications Medium polish parts | Surface Roughness (Ra µm) 0.10 - 0.15 |

SPI Finish SPI B-3 | Description 320 Grit Paper | Typical Applications Medium - low polish parts | Surface Roughness (Ra µm) 0.28 - 0.32 |

SPI Finish SPI C-1 | Description 600 Stone | Typical Applications Low polish parts | Surface Roughness (Ra µm) 0.35 - 0.40 |

SPI Finish SPI C-2 | Description 400 Stone | Typical Applications Low polish parts | Surface Roughness (Ra µm) 0.45 - 0.55 |

SPI Finish SPI C-3 | Description 320 Stone | Typical Applications Low polish parts | Surface Roughness (Ra µm) 0.63 - 0.70 |

SPI Finish SPI D-1 | Description Dry Blast Glass Bead | Typical Applications Satin finish | Surface Roughness (Ra µm) 0.80 - 1.00 |

SPI Finish SPI D-2 | Description Dry Blast #240 Oxide | Typical Applications Dull finish | Surface Roughness (Ra µm) 1.00 - 2.80 |

SPI Finish SPI D-3 | Description Dry Blast #24 Oxide | Typical Applications Dull finish | Surface Roughness (Ra µm) 3.20 - 18.00 |

Mold-Tech Textured Finishes

Standex Engraving Mold-Tech is a standardized mold texturing option typically used for commercial or saleable goods. Mold-Tech is serialized in four series, A through D. Most commonly the Mold-Tech Series A finishes are used on products as it has a range of fine to coarse matte finishes that do not require laser, masked chemical etching, or other engineered texturing processes. Mold-Tech finishes are categorized by their serial number and texture depth. A more aggressive draft angle is needed with Mold-Tech because mold texturing has more coarse features than SPI finishes, it is recommended to add 1.5° of draft for every 0.001" of texture depth.

FREE Injection Molding Design Guide

Mold-Tech A Finishes

| Mold-Tech Serial Number | Texture Depth (inch) | Application | Minimum Draft |

|---|---|---|---|

Mold-Tech Serial Number MT-11010 | Texture Depth (inch) 0.001" | Application Dull matte finish | Minimum Draft 1.5° |

Mold-Tech Serial Number MT-11020 | Texture Depth (inch) 0.0015" | Application Coarse matte finish | Minimum Draft 2.25° |

Mold-Tech Serial Number MT-11030 | Texture Depth (inch) 0.002" | Application Coarse matte finish | Minimum Draft 3° |

VDI 3400 Surface Finish (known as VDI surface finish) refers to the mold texture standard Verein Deutscher Ingenieure (VDI), the Society of German Engineers. The VDI 3400 surface finish is mainly processed by Electrical Discharge Machining (EDM) when mold machining. VDI is an international standard for mold texturing of matte surfaces. The EDM surface gives a fine-to-coarse grain depending on the selection. VDI is not the same as Mold-Tech, which is applied through various techniques from manual finishing to laser etching to chemical etching with patterns. However, some textures may have near equivalencies, such as SPI D-3, VDI 33, and MT-11020, all looking very similar. In similar aspects, VDI 12 and SPI C-1 are equivalent.

SPI Mold Finishes

VDI (EDM) Mold Texture Values

| VDI Value | Description | Applications | Surface Roughness (Ra µm) |

|---|---|---|---|

VDI Value VDI 12 | Description 600 Stone | Applications Low polish parts | Surface Roughness (Ra µm) 0.40 |

VDI Value VDI 15 | Description 400 Stone | Applications Low polish parts | Surface Roughness (Ra µm) 0.56 |

VDI Value VDI 18 | Description Dry Blast Glass Bead | Applications Satin finish | Surface Roughness (Ra µm) 0.80 |

VDI Value VDI 21 | Description Dry Blast # 240 Oxide | Applications Dull finish | Surface Roughness (Ra µm) 1.12 |

VDI Value VDI 24 | Description Dry Blast # 240 Oxide | Applications Dull finish | Surface Roughness (Ra µm) 1.60 |

VDI Value VDI 27 | Description Dry Blast # 240 Oxide | Applications Dull finish | Surface Roughness (Ra µm) 2.24 |

VDI Value VDI 30 | Description Dry Blast # 24 Oxide | Applications Dull finish | Surface Roughness (Ra µm) 3.15 |

VDI Value VDI 33 | Description Dry Blast # 24 Oxide | Applications Dull finish | Surface Roughness (Ra µm) 4.50 |

VDI Value VDI 36 | Description Dry Blast # 24 Oxide | Applications Dull finish | Surface Roughness (Ra µm) 6.30 |

VDI Value VDI 39 | Description Dry Blast # 24 Oxide | Applications Dull finish | Surface Roughness (Ra µm) 9.00 |

VDI Value VDI 42 | Description Dry Blast # 24 Oxide | Applications Dull finish | Surface Roughness (Ra µm) 12.50 |

VDI Value VDI 45 | Description Dry Blast # 24 Oxide | Applications Dull finish | Surface Roughness (Ra µm) 18.00 |

Unless otherwise specified, an injection molded part will typically have an SPI B-2 default finish to enable better part release from the mold and remove tool marks. Surface finishes can be applied to some or all faces; for example, an opaque molded part can have a custom outer surface. The interior, non-cosmetic surface, can remain default. Multiple finishes and texturing can be applied to a single tool cavity if required. Transparent parts are typically polished on both sides to achieve the highest clarity.

Xometry offers a wide variety of surface finishes and additional mold textures to ensure that your parts meet all of their structural and cosmetic requirements. Learn more about our injection molding service.