Material Selection Gallery

Custom Materials

Not seeing what you are looking for? We can source it! Submit your quote request using "Other" in the material drop-down, write in your request, and our expert team will be happy to review the project!

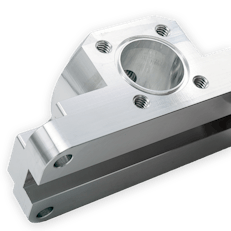

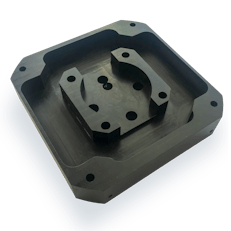

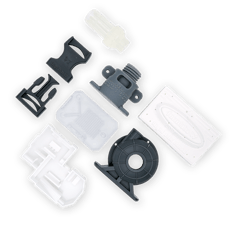

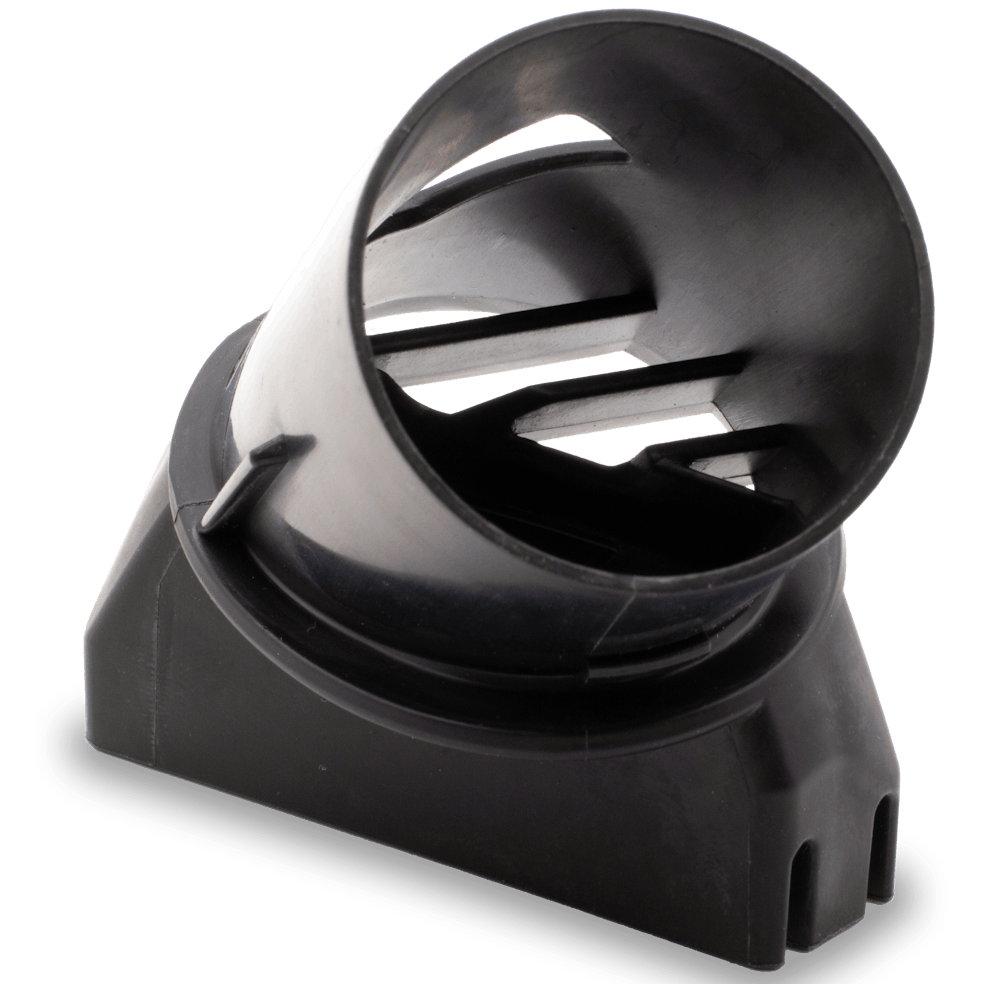

CNC Machined Plastics

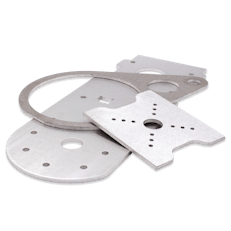

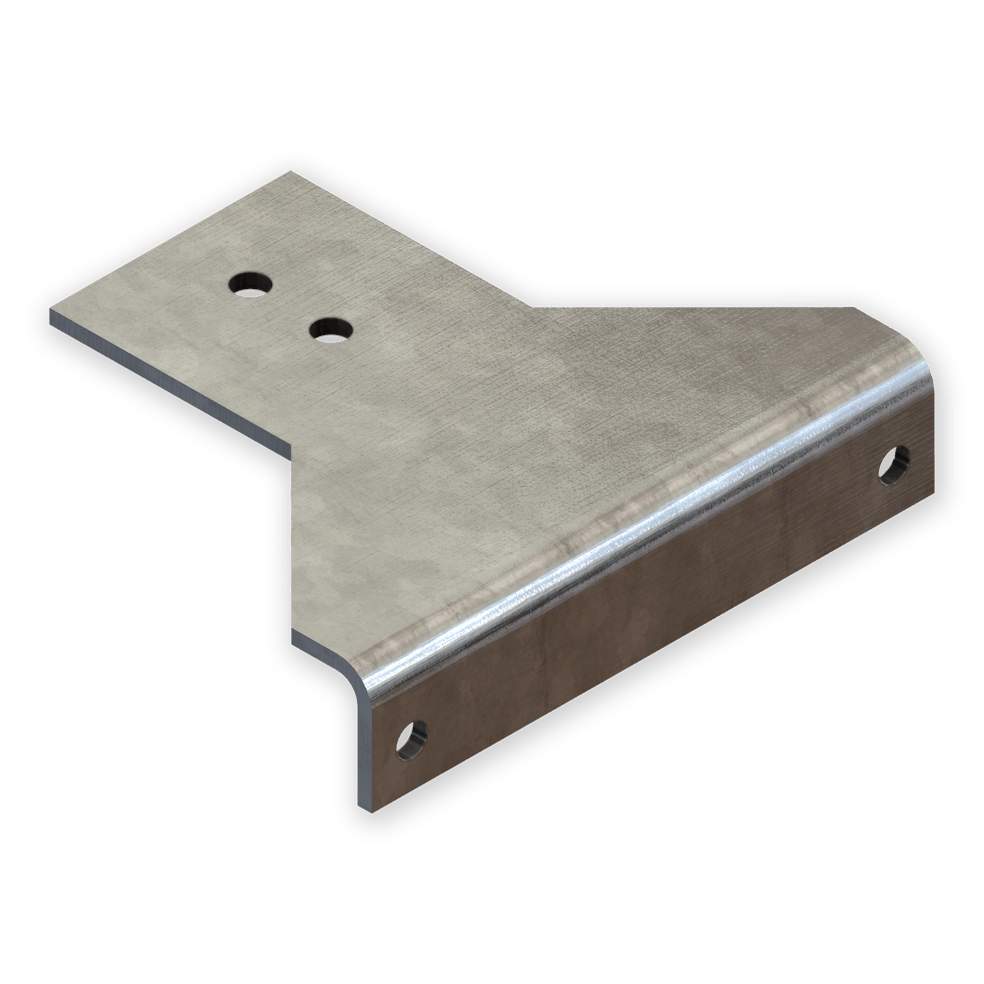

Sheet Metal Materials

- Aluminum Sheet Metal Materials

- Brass Sheet Metal Materials

- Bronze Sheet Metal Materials

- Copper Sheet Metal Materials

- Stainless Steel Sheet Metal Materials

- Steel Sheet Metal Materials

- Titanium Sheet Metal Materials

3D Printed Metals

DMLS / DMLM Metal 3D Printing

Binder Jet Metal 3D Printing

- X1 Metal 420i (Stainless Steel Infiltrated with Bronze)

- X1 Metal 316i (Stainless Steel Infiltrated with Bronze)

- 316L (single alloy)

- 3D Printed Single Alloy 17-4PH Stainless Steel (View spec sheet)

- 3D Printed Single Alloy 304L Stainless Steel, 97% dense (View spec sheet)

- 3D Printed Single Alloy M2 Tool Steel (View spec sheet)

- 3D Printed Single Alloy Inconel 718, 99.2% dense (View spec sheet)

- 3D Printed Tungsten-Bronze metal composite, 97% dense (View spec sheet)

Urethane Casting Materials

Rigid Polyurethane (Black, Natural, Color-Match)

- ABS-like, FR

- General Purpose Shore 78D

- Glass-Filled Nylon-like Shore 85D

- Polypropylene-like Shore D65-D75

- Polycarbonate-like Shore 84D

Rigid Clear Polyurethane (Colorless)

- Rigid Clear Shore D 80

Rubber-like Polyurethane (Black, Natural, Color-Match)

- Rubber-like Shore A 25-35, ranging to Shore A 85-95

Clear Rubber-like Polyurethane (Colorless)

- Clear Rubber-like Shore A 40-50, ranging to Shore A 85-95

Cast Silicone Materials

- Shore A 10 (TC-5005 or equiv.), ranging to Shore A 50-60 (Smooth‑Sil™ 960 or equiv.)

Learn more on our urethane and silicone casting page.

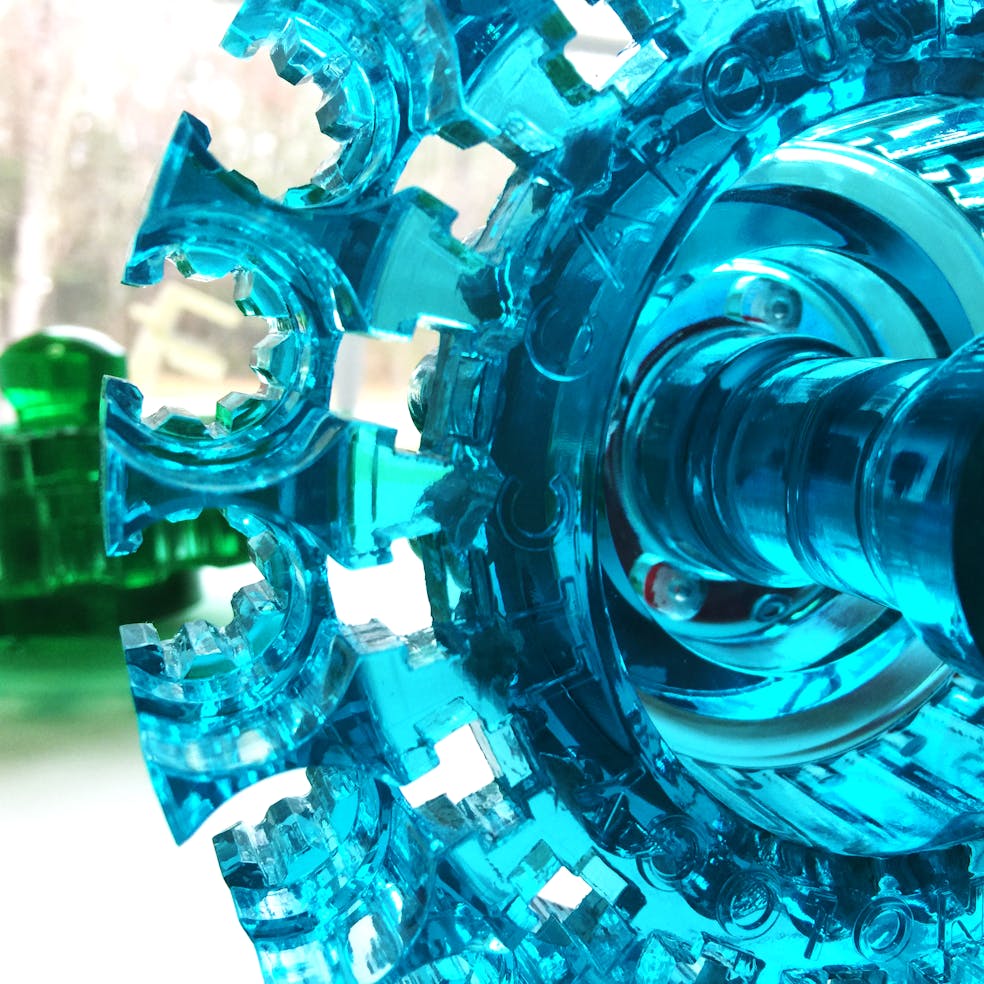

Injection Molding Plastics and Elastomers

Rigid plastic materials

- ABS (acrylonitrile butadiene styrene)

- ASA (acrylonitrile styrene acrylate)

- CA (cellulose acetate)

- HDPE (high-density polyethylene)

- LCP (liquid crystal polymer)

- LDPE (low-density polyethylene)

- PA 6 (polyamide 6, nylon 6)

- PA 6/6 (polyamide 6/6, nylon 6/6)

- PARA (polyarylamide)

- PBT (polybutylene terephthalate, Valox)

- PBT-PET (polybutylene terephthalate-polyethylene terephthalate)

- PC (polycarbonate)

- PC-ABS (polycarbonate-acrylonitrile butadiene styrene)

- PC-PBT (polycarbonate-polybutylene terephthalate, Xenoy)

- PC-PET (polycarbonate-polyethylene terephthalate)

- PCT (polycyclohexylenedimethylene terephthalate)

- PE (polyethylene

- PEEK (polyether ether ketone)

- PEI (polyetherimide, Ultem)

- PE-PP (polyethylene-polypropylene)

- PE-PS (polyethylene-polystyrene)

- PES (polyethersulfone)

- PET (polyethylene terephthalate, Rynite)

- PLA (polylactic acid)

- PMMA (polymethyl methacrylate, acrylic)

- POM (acetal polyoxymethylene, Delrin)

- PP (polypropylene)

- PPA (polyphthalamide)

- PPS (polyphenylene sulfide, Ryton)

- PS (polystyrene)

- PS-PPE (polystyrene-polyphenyl ethers, Noryl)

- PSU (polysulfone, Udel)

- PVC (polyvinyl chloride (Shore D)

- PVDF (polyvinylidene fluoride, Kynar)

- SAN (styrene acrylonitrile)

- TPO (thermoplastic polyolefin)

- TPU (thermoplastic polyurethane (Shore D))

Elastomer/Rubber molded materials

- EPDM (ethylene propylene diene monomer rubber (Viton))

- PEBA (polyether block amide)

- PVC (polyvinyl chloride (Shore A))

- TPE (thermoplastic elastomer)

- TPU (thermoplastic polyurethane (Shore A))

- TPV (thermoplastics elastomer, vulcanized rubber (Santoprene))

- LSR (liquid silicone rubber)

See more details on injection molding materials.

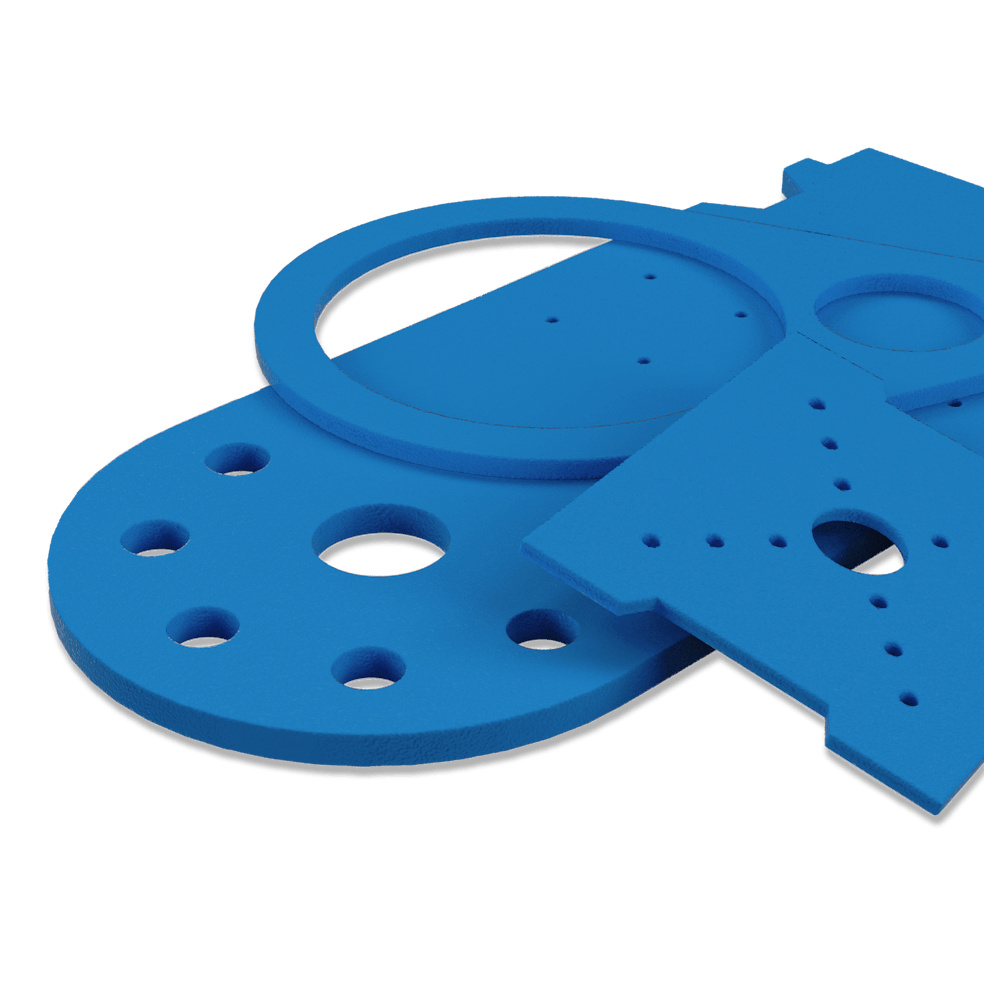

Sheet Cut Foam Materials

- EVA Foam, Black

- EVA Foam, Blue

- Extra Soft PU Foam, Adhesive Backed, Black

- Extra Soft PU Foam, Black

- Flame-Retardant PU Air Filter Pad, Gray

- Flame-Retardant Silicone Foam, Gray

- High Temp Silicone Foam, Adhesive Backed, Red

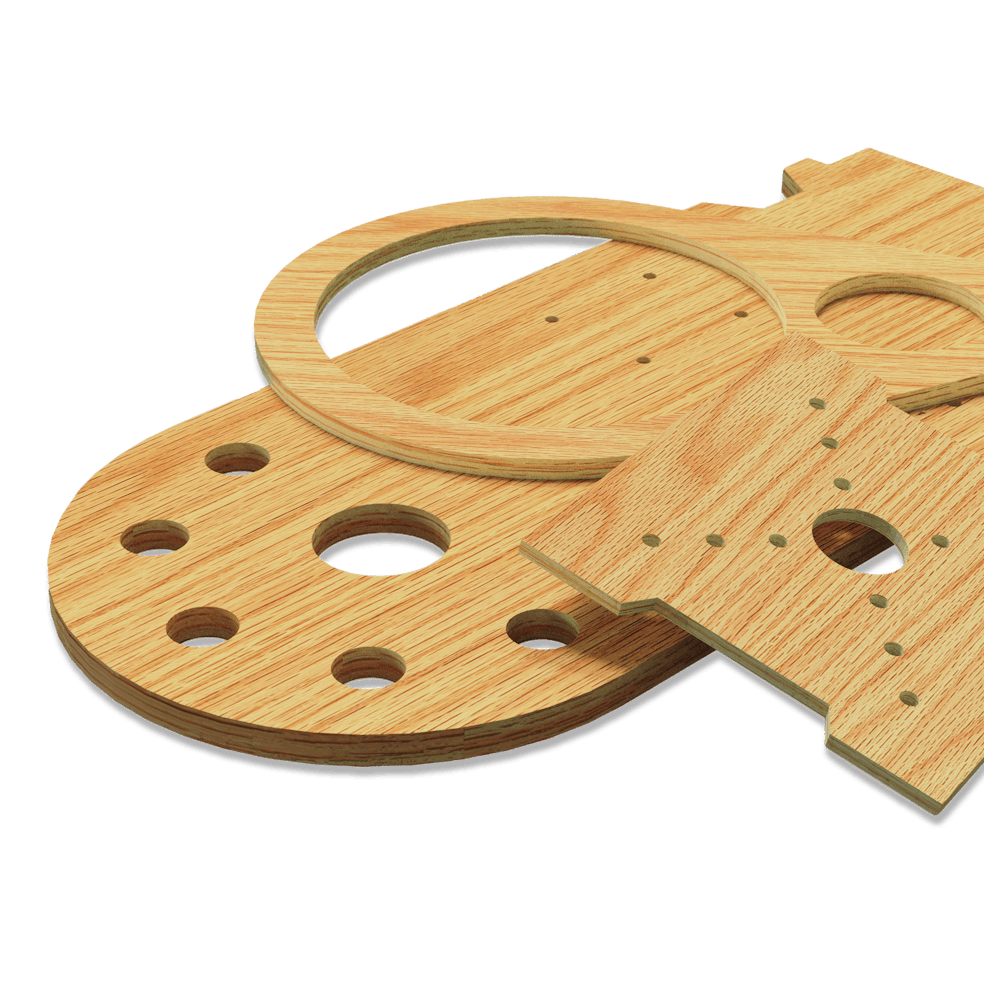

Sheet Cut Wood Materials

- Cherry Hardwood

- Hardboard (Masonite)

- MDF

- Poplar Hardwood

- Red Oak Hardwood

- Uncoated Wood Laminate (Plywood), Birch

Sheet Cut Rubber Materials

- Buna-N Rubber, Adhesive-Backed, Black

- Buna-N Rubber, Black

- Cork and Buna-N Blend, Brown

- EPDM

- High Temp Silicone Rubber, Adhesive-Backed, Red

- High Temp Silicone Rubber, Red

- Paper Fiber and Buna-N Blend, Gray

- PTFE Gasket Material

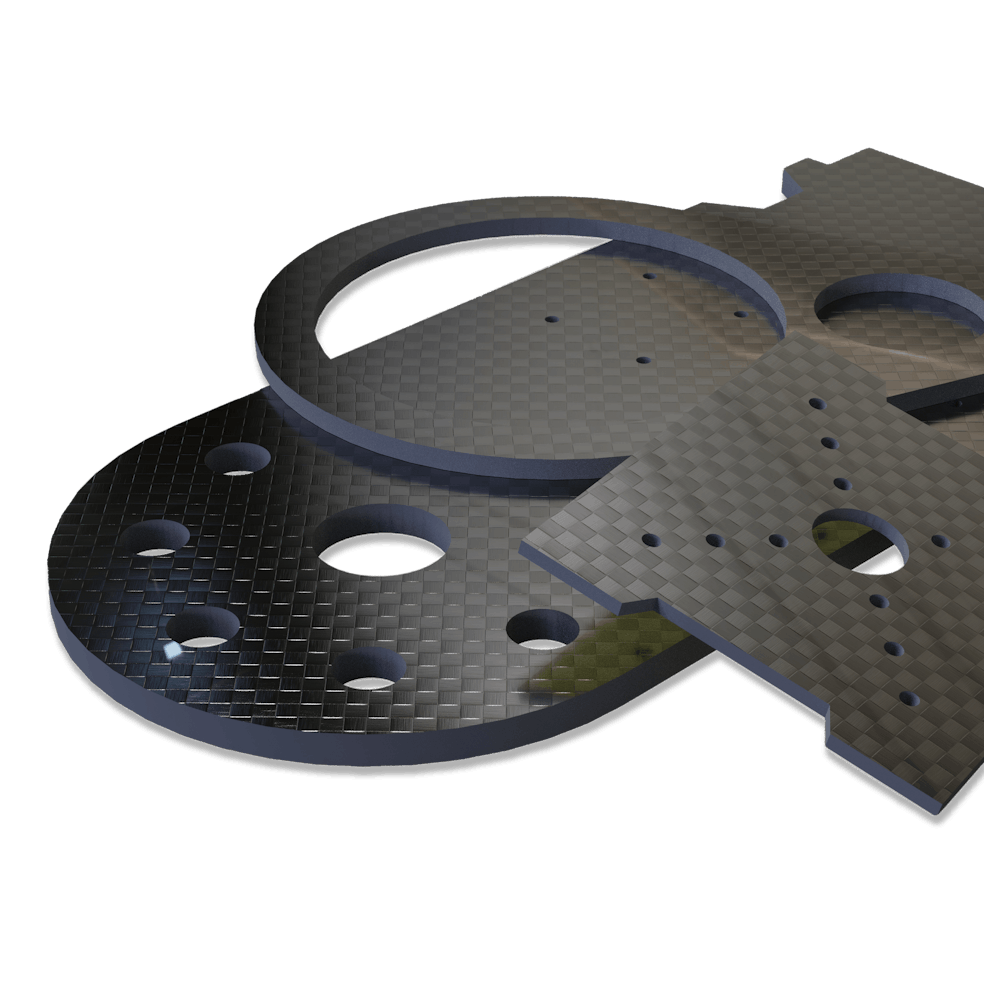

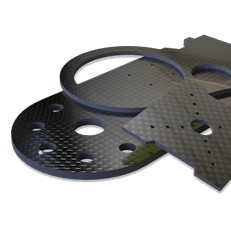

Sheet Cut Composite Materials

- Carbon Fiber

- Garolite G-10 (FR4), Black

- Garolite G-11 (FR5), Green

- Garolite LE (Phenolic), Brown