Using a DXF file for quoting

Xometry's Sheet Cutting Services utilize laser cutting and waterjet cutting to produce affordable flat parts with custom outlines. We accept various file types, including STEP, SLDPRT, IPT, PRT, SAT, and DXF. DXF files are uniquely suited for sheet cutting because they are two-dimensional, top-down representations of the final part.

DXF files are exported from CAD software and even many art and design programs. DXF files are vectored, meaning that a mathematical formula versus pixels defines the lines. Unlike raster images such as photos, vectored DXF files will not lose any resolution regardless of how far you zoom in on the image.

DXF Quick Tips

Remove all duplicate or overlapping lines, curves, points, or other entities.

The file should not contain open curves. Close all open curves so that the 2D sketch can be extruded.

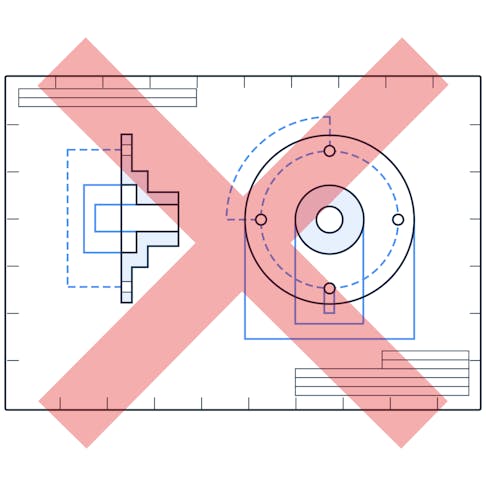

The drawing should have all curves closed and no overlapping or duplicate lines, as shown here.

Remove any title block information, notes, and dimensions.

The file should not contain extra curves or lines preventing the detection of boundaries.

The file should contain only the outline of the part to cut, scaled 1:1, with all curves closed, and no overlapping entities.

DXF Requirements

Cut lines only

The best way to get an instant quote with a DXF is to upload a cut file and not the full drawing. Using a DXF will create a quote for a “flat cut” sheet part without bends. If there are bends in the part, the best way to quote is by using a 3D CAD model (STEP or other format) formed to the final shape.

Scale 1:1

Your drawing should be scaled to the exact size of the final part.

Rules for units

The units will either be in millimeters or inches. If the design was made with a different unit, you must update your units and re-export.

Xometry will choose your units based on the following rules:

- If the maximum length of your DXF is over 48.5 units, Xometry assumes the DXF is in millimeters.

- If the maximum length is less than 1 unit, Xometry will assume the DXF is in inches.

- Otherwise the units in the file are kept.

Put tolerance information in a separate file

If your parts require specific tolerances beyond our default manufacturing standards, tolerance callouts will need to be specified in the instant quote and included in an attached drawing for accurate pricing.

No title blocks

Extra-drawn features can be confused with cut geometry and cause the file processing to fail. As part of the geometry process, multiple layers are merged into a single layer.

All geometry must be in the XY-plane

All drawing features must be oriented in the XY plane. Make sure the file is a 2D (not 3D) DXF file. Remember, instant quotes are supported for our Sheet Cutting process only with DXF files.

No inserts or assembled components

Files cannot contain inserts or multiple assembled components.

Become an Expert in All things Sheet Metal Fab