Tips For Designing Custom Parts With SLS 3D Printing

Selective laser sintering (SLS) is one of the most popular processes that Xometry customers use. Learn more about how it works and the general tolerance and wall thicknesses that work best for SLS.

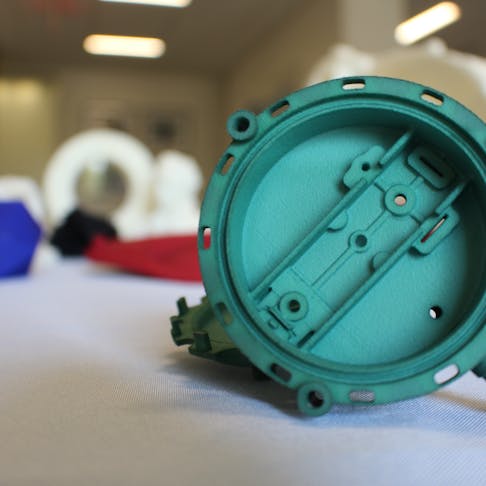

Selective laser sintering (SLS) is one of the most common processes chosen by our engineers for the 3D printing of rapid prototype and low volume production parts. SLS works by utilizing a high-powered laser to fuse cross sections of nylon particles together in a powder bed, repeating this process over and over to create a complete part.

When designing parts to be 3D printed using SLS, there are a number of important factors to consider in order to avoid help avoid build failures of your parts. In this post we’ll briefly examine some of the pitfalls to try and avoid when designing parts for SLS 3D printing.

General Tolerances

When it comes to general tolerances of SLS 3D printing, the most important thing to remember is that larger parts with thicker geometries and uneven wall thicknesses are much more liable to experience shrinkage and warping throughout the print process. Because of this, a maximum build volume of 13” X 13” X 20” is preferred.

We also recommend a 0.006” (0.15mm) offset to small gaps and holes in your part, and a 0.005” surface offset on mating surfaces (male and female) to increase chances of success.

Wall Thickness

Dealing with thin walls is one of the most frustrating aspects of designing custom parts for 3D printing, in any material. When walls are designed too thin, your part will often be too fragile to even print, let alone safely removing any support structures that have been included.

If you are planning on using SLS, the engineers at Xometry recommend 0.028” (0.7mm) wall thickness on any part with over 0.040” (1mm). If your part design has walls that are any thinner than 0.020” (.5mm), this can cause problems, as they will often deviate and over-thicken due to excessive heat from the laser. As a rule of thumb, the larger your part is, the thicker the walls will need to be, but there is usually no need for a part to have walls over 0.200” (5.0mm).

In general, we recommend following similar wall design rules as you would use for injection molding in order to achieve more uniform and consistent results for your parts.