Custom Plastic Injection Molding Service

Auto quote estimates for custom plastic molded prototypes and production runs | Virtually endless material and finishing options | Expert engineering reviews and project management included with every order

Injection Molding with Xometry

Injection molding is the most cost-effective method for producing consistent, high-quality plastic parts at scale. It offers the highest variety of materials, colors, and finishing options compared to other manufacturing methods.

Xometry's custom injection molding service provides on-demand prototype and production solutions. Through our vast supplier network, we find the right partner to mold your parts without design compromises and at the right price. Our team offers expert consultation and project management, with deep experience in every industry, including medical injection molding, liquid silicone rubber molding, domestic and China injection molding, as well as ITAR injection molding for sensitive projects.

Xometry turns the complex nature of injection molding into a simple process. To get started, simply upload your 3D CAD file to the Xometry Instant Quoting Engine®. Most projects qualify for an auto-quoted estimate, allowing you to budget and plan your project accordingly without waiting for responses. Once you're ready, submit your request for review, and our team will work with you closely at every step!

Injection Molding Services Capabilities

| Capability | Details |

|---|---|

Capability Lead Time | Details As fast as 5 business days; 3 weeks is typical for most projects |

Capability Production Options | Details Domestic and international |

Capability Materials | Details Most plastics, including custom sourcing and matching; see materials list below |

Capability Machines & Tooling | Details Single, multi-cavity, and family molds; 50 to 3,700+ ton presses; automated side actions or hand-loaded cores |

Capability Inspection and Certification Options | Details ISO 9001, AS9100, ISO 13485, IATF 16949 UL, ITAR, and ISO 7 and 8 Medical Clean Rooms; FAI and PAPP available |

Capability Tool Ownership | Details Customer-owned with mold maintenance |

Capability Mold Cavity Tolerances | Details +/- 0.005" when machining the mold and an additional +/- 0.002" per inch when calculating for shrink rate |

Capability Part to Part Repeatability | Details +/- 0.004" or less |

Capability Critical Feature Tolerances | Details Tighter tolerances can be requested and may increase the cost of tooling because of additional sampling and grooming. Xometry will mill to a steel-safe condition on critical features. |

Capability Mold Classes | Details Steel and aluminum tooling with production grades range from Class 105 (prototype) to Class 101 (extremely high production) molds |

This table depicts the general tolerances for Xometry’s plastic injection molding service and accounts for adequate draft, radii, and coring for manufacturability. Learn more about our injection molding manufacturing standards.

Plan Your Budget and Timeline With an Auto-Quoted Estimate

How Custom Plastic Injection Molding Works

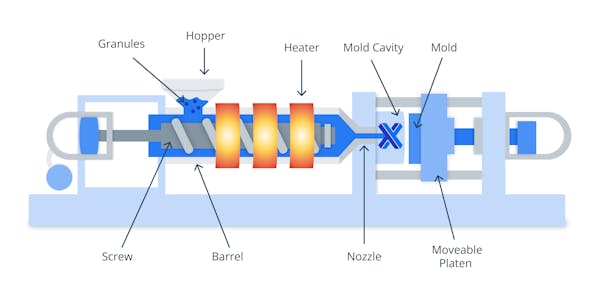

The plastic injection molding process requires an injection molding machine, raw plastic material, and a machined mold. The raw plastic material is first melted in the injection unit and is then injected into the mold—most often machined from steel or aluminum—where it cools and solidifies into the final plastic part.

At Xometry, we first review your plastic injection molding online quote and parts for manufacturability, then consult with you to ensure your specifications, lead time, and price fit your project needs. We use your 3D CAD to CNC machine a high-quality injection mold. Once the molded parts are created, Xometry sends samples (T1) for approval. Once the mold is refined and approved, Xometry begins production. We use this process to mold everything from the smallest medical insert up to large automotive, aerospace, and defense parts.

Injection Molding Materials

Rigid Plastic Materials

Xometry offers a vast array of rigid plastic materials, including:

- ABS (acrylonitrile butadiene styrene)

High-strength general-purpose engineering plastic, used for many commercial products. - ASA (acrylonitrile styrene acrylate)

A material very similar to ABS with higher resistance to fading and better suited for outdoor use. - CA (cellulose acetate)

Typically used in eyeglasses and film, CA is a flexible clear material that can be used in food contact. - HDPE (high-density polyethylene)

Excellent strength-to-weight ratio and chemical resistance. It is often used for fuel tanks, connector insulators, and food containers. HDPE is also used in outdoor equipment like playgrounds. - LCP (liquid crystal polymer)

LCP has mechanics even at elevated temperatures as well as low dielectric constants. This material provides exceptional features for micromolding and thin walled components. LCP is popular for electrical connectors and interconnects as well as medical devices. - LDPE (low-density polyethylene)

A flexible and tough material with lower density versus HDPE. LDPE does not react to acids, bases, or alcohols. Useful for trays, snap lids, and general-purpose containers. - PA 6 (polyamide 6, nylon 6)

Offers increased mechanical strength, rigidity, good stability under heat, and/or chemical resistance. - PA 6/6 (polyamide 6/6, nylon 6/6)

Offers increased mechanical strength, rigidity, good stability under heat, and/or chemical resistance. - PARA (polyarylamide)

Often combined with infills such as glass or mineral fibers, PARA creates rigid parts with low creep and a slower rate of water absorption than nylon (PA). PARA is excellent for structural components in handheld and medical electronics. - PBT (polybutylene terephthalate, Valox)

A common electronic insulator with a polyester base. Highly used in automotive as a longer-wear alternative to nylon. - PBT-PET (polybutylene terephthalate-polyethylene terephthalate)

A compounded blend of PBT and PET. - PC (polycarbonate)

A clear or colored, lightweight, glass-like plastic that is heavily used across multiple industries. PC is impact resistant, holds great feature detail, and can be used for safety equipment, lenses, electronic devices, and much more. - PC-ABS (polycarbonate-acrylonitrile butadiene styrene)

The best of both PC and ABS. Higher-strength engineering thermoplastic with slightly more flexibility than standard polycarbonate. - PC-PBT (polycarbonate-polybutylene terephthalate, Xenoy)

A tough and rigid material resistant to lubricants, solvents, and cleaning agents. Very common in electronic enclosures. - PC-PET (polycarbonate-polyethylene terephthalate)

A blend of PC and PET provides tough and chemically resistant results and can be used as an alternate to PC-ABS. It endures harsh solvents and cleaners, making it excellent for sports equipment and healthcare applications. - PCT (polycyclohexylenedimethylene terephthalate)

A thermoplastic polyester that typically outperforms PET due to lower moisture absorption and better environmental stability. PCT is often used for connectors and switches. - PE (polyethylene)

One of the most common plastics used in the world, PE has high ductility, abrasion resistance, and chemical resistance. PE is often described by its molecular weight, such as UHMW PE (ultra-high molecular weight), LDPE (low density), or HDPE (high density). PE is used in packaging, tubing, films, bottles, and more. - PEEK (polyether ether ketone)

Offering excellent tensile strength that surpasses most plastics, PEEK is often used as a lightweight substitute for metal parts in high-temperature, high-stress applications. PEEK resists chemicals, wear, and moisture. - PEI (polyetherimide, Ultem)

Known best for its extremely high heat and flame resistance, PEI is used for many medical applications and is more affordable than PEEK. - PE-PP (polyethylene-polypropylene)

A resin blend of the polyolefin’s polypropylene and polyethylene. - PE-PS (polyethylene-polystyrene)

A resin blend of the polyethylene and polystyrene. - PES (polyethersulfone)

A rigid, transparent plastic that is chemically inert, biocompatible, and sterilizable. PES is suitable for food-contact devices such as coffee machine components as well as aerospace and automotive where chemical exposure is high. - PET (polyethylene terephthalate, Rynite)

Also abbreviated PETE, this is a clear, strong, and lightweight PE resin heavily used in food packaging, soda bottles, jars, and more. The material is food-safe. PET is recyclable with a resin code of 1. - PLA (polylactic acid)

A biodegradable and renewable plastic. PLA has a relatively low glass transition temperature and is common in short-use applications. - PMMA (polymethyl methacrylate, acrylic)

A clear glass-like plastic. Good wear and tear properties. Great for outdoor use. - POM (acetal polyoxymethylene, Delrin)

Good moisture resistance, high wear-resistance, and low friction. - PP (polypropylene)

Polypropylene has excellent electrical properties and little or no moisture absorption. It carries light loads for a long period in varying temperatures. It can be molded into parts requiring chemical or corrosion resistance. - PPA (polyphthalamide)

A subset of nylons (polyamide) that typically exhibit a higher melting point and lower moisture absorption. PPA is typically used in automotive and industrial applications because it can withstand harsh chemicals. PPA is good for fuel and fluid manifolds and headlight housings. - PPS (polyphenylene sulfide, Ryton)

A high-performance thermoplastic with extreme resistance to solvents. - PS (polystyrene): A clear, hard, and brittle material widely used for food packaging, clamshell containers, and even disposable cutlery.

- PS-PPE (polystyrene-polyphenyl ethers, Noryl)

Exhibiting high heat and flame resistance, PPE-PS has high stiffness and tensile strength even at elevated temperatures. - PSU (polysulfone, Udel)

A rigid, stiff, and transparent plastic which is a higher-performance alternative to polycarbonate. - PVC (polyvinyl chloride (Shore D))

A rigid, general-use plastic that is common in plumbing, non-food packaging, and trimming. - PVDF (polyvinylidene fluoride, Kynar)

A chemically inert, high-temperature material. Due to its low friction, PVDF is used in plumbing parts, bearings, chemical handling, electrical wire insulation, and tubing. - SAN (styrene acrylonitrile)

A polystyrene that is heat resistant and transparent. Due to its relationship with polystyrene, SAN is low cost and has enhanced clarity and shine. SAN is common in household goods, door handles, and kitchenware. - TPO (thermoplastic polyolefin)

A flexible plastic with good chemical resistance but lower temperature resistance compared to PP. - TPU (thermoplastic polyurethane (Shore D))

A tough, highly abrasion-resistant resin that bridges the gap between rubbers and plastics. TPUs can be formulated to be rigid or elastomeric. TPU exhibits a high flex before break and is ideal for wheels and door panels.

If you do not see the material stock you are looking for, please choose “Other" under the material drop-down on your quote page and submit for an expert engineering review once you have specified features, tolerances, inspection needs, and quantities required.

Elastomer and Rubber Molded Materials

Elastomeric parts can be manufactured through injection molding, transfer molding, or compression molding. When getting a quote through Xometry, our team can help you decide the best method based on the part geometry, estimated annual volume, and the type of material required.

- EPDM (ethylene propylene diene monomer rubber (Viton))

One of the highest performing rubber elastomers with high heat resistance, chemical resistance, and moisture sealing properties. EPDM is commonly found in automotive seals, gaskets, O-rings, and electrical insulators. - PEBA (polyether block amide)

A soft, flexible, plastic or elastomer used for medical devices such as catheters. PEBA foams are used for padding, shoe insoles, and sports equipment. PEBA is resistant to moisture and UV exposure. - PVC (polyvinyl chloride (Shore A))

A soft rubber-like, general use elastomer, that is common in outdoor products, protective films, and mats. Shore A rubber-like PVC requires plasticizers to improve its flexibility from its typical rigid state. PVC is flame retardant due to self-extinguishing properties. - TPE (thermoplastic elastomer)

A broad class of elastomers that behave like a thermoset with high flex and elasticity but process like a thermoplastic through molding. TPE is an umbrella term for many unique elastomer classes. - TPU (thermoplastic polyurethane (Shore A))

A tough, highly abrasion-resistant elastomer that bridges the gap between rubbers and plastics. TPUs can be formulated to be rigid or elastomeric. TPU exhibits a high flex before break and is ideal for flexible tires, skateboard wheels, and weatherproof gaskets. - TPV (thermoplastics elastomer, vulcanized rubber (Santoprene))

An excellent elastomer with high versatility due to temperature resistance, compression, and elasticity. - LSR (liquid silicone rubber)

Silicones are versatile rubber materials offering food and biocompatibility, extreme heat resistance, and excellent flexibility. LSR is used for medical devices, automotive, aerospace, and consumer products. Liquid silicone rubber molding is a specialized process different from traditional injection molding.

Several plastic injection molding, liquid silicone molding, and compression molding options are available for an online quote. If you do not see the material stock you are looking for, please choose “Other" under the material drop-down on your quote page and submit for an expert engineering review once you have specified features, tolerances, inspection needs, and quantities required.

Injection Mold Finishes & Post-Processing Options

Standard Finish

Moldmaker's choice of finish. Typically SPI B-2, depending on geometry and drafts. Interior, non-cosmetic faces, are typically as-machined.

SPI Finishes

Range of Society of Plastics Industry (SPI) finishes from Grade 3 diamond / high polish to 320 stone low polish. Finishes include: SPI A-1, SPI A-2, SPI A-3, SPI B-1, SPI B-2, SPI B-3, SPI C-1, SPI C-2, SPI C-3, SPI D-1, SPI D-2, and SPI D-3

MoldTech Finishes (Mold Texturing)

Range of finishes including matte, swirls, lines, and patterns. Our most common texture finishes include: MoldTech MT11010, MoldTech MT11020, and MoldTech MT11030. Other textured finishes can be added by request.

Other Textures - VDI

VDI 3400 Surface Finish (commonly known as VDI surface finish) refers to the mold texture standard set by Verein Deutscher Ingenieure (VDI), the Society of German Engineers. This is mainly processed by EDM machining, producing fine to coarse matte finishes.

As Molded

No secondary polishing or grinding. Part will show tooling marks.

Threaded Inserts

We can install most commonly used standard inserts in UNF and metric sizes.

Pad Printing

Transfer a 2D image onto a 3D part. All images are subject to review.

Laser Engraving

Engrave part numbers, logos, and more onto your parts.

Assembly

Xometry can assemble and label injection molded parts. Discuss your needs with your Xometry representative.

An Overview of Injection Molded Surface Finishes

Applications and Advantages of a Plastic Injection Molding Service

Low-cost tooling options allow for rapid injection molding, enabling us to produce parts as fast as 5 business days at affordable prices.

Injection molding is an ideal solution for end-use production parts, delivering superior performance over CNC machined or 3D printed equivalents. A vast selection of resins allows parts to be tailored for specific properties and solvent compatibility. The process uses high-precision molds to produce identical parts with tight tolerances and intricate details, scaling from low-volume to mass production quantities of over one million units.

Our molding services are ready to meet your qualification and quality requirements. We offer ISO 9001, AS9100, ISO 13485, IATF 16949, UL, ITAR, and ISO 7 and 8 Medical Clean Room molding.

Why Use Xometry Injection Mold Services?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Vetted Network

We are ISO 9001:2015, ISO 13485, AS9100D, and IATF 16949 certified. Only the top shops that apply to become suppliers make it through our qualification process.

Instant Pricing and Lead Time Estimates

Streamline your budgeting and procurement process with the Xometry Instant Quoting Engine®. Upload your 3D CAD files to receive an auto-quoted estimate for pricing and lead times, allowing you to plan your project without the typical delays of waiting for a manual quote. This powerful tool saves you valuable time by providing the information you need up front. When you’re ready to move forward, our team of experts will thoroughly review your project to confirm and finalize your quote and provide consultation to ensure your project is set up for success.

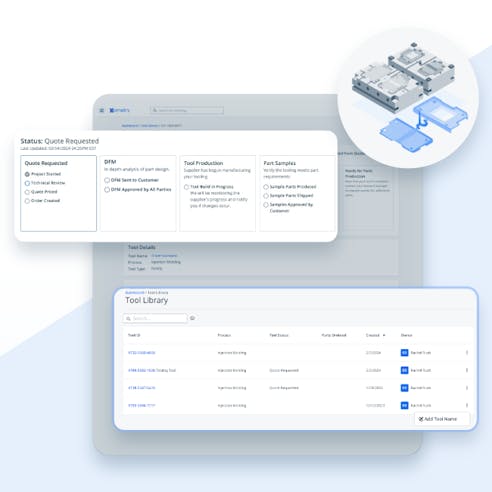

Built-In Tool Management

Xometry's platform has built-in features that make managing tooled projects a breeze, giving customers greater transparency into production. Find all your tooling quotes and orders in one space with your Tool Library. From there, you can explore their Tool Details page, which covers the current status, milestones, tool specifics, and activity related to that tool. You can also easily find and contact the Xometry team member assigned to your project, no matter the project's current phase.

Our Tool Library and Tool Details pages provide multiple benefits, such as:

- Better Management of Tooled Quotes & Orders

- Tool Organization & Categorization

- Detailed Status Updates & Tooling Information

- Easily Connect with Experts

- Project Transparency

Custom Injection Moldings Design Guidelines

| Feature | Tip |

|---|---|

Feature Undercuts | Tip Reduce undercuts, which will increase the complexity and cost of the tool ejection mechanisms, by adding in pass-thru coring. |

Feature Wall Thickness | Tip Prevent wall sink and voids by maintaining an even wall thickness. Thinner walls reduce cycle time and reduce costs. |

Feature Drafts | Tip Ensure parts are designed with a minimum draft angle of 0.5°, or up to 5°, for faces with medium textures. |

Feature Ribs/Gussets | Tip Ribs should be 40-60% the thickness of outer walls and should still maintain draft. |

Feature Bosses | Tip Bosses should be designed at a depth of 30% the wall thickness and with a 30% edge groove. Attach them to side walls or ribs for structural integrity. |

To see these design-for-manufacturing recommendations in detail, view our Injection Molding Design Guide.

Looking for More Design Tips?

Our free injection molding guide will help steer you in the right direction!

Injection Molding FAQs

What industries use injection molding?

Injection molding is used across a wide range of industries including aerospace, medical devices, consumer goods, energy, electronics, automotive, robotics, toys, and more.

What is the difference between molding and printing?

With the molding process, plastic or metal parts are created inside a mold. They are then removed from the mold as fully-formed parts. 3D printing, on the other hand, is an additive manufacturing process, meaning that the part is built layer-by-layer using processes like deposition or sintering.

What is the process after ordering?

After receiving the order, the statement of work is reviewed by one of our manufacturing engineers. A case manager is assigned, and an appropriate manufacturing supplier is identified. A comprehensive DFM/PEG report is created and provided for approval. Upon approval, tooling and mold production is commenced. T1 samples are produced and shipped for approval. Upon approval, the remaining parts are made.

Who owns the tool?

At Xometry, our customers own their injection mold tools! After a run is complete, the tool will remain at our facilities. Tools can be shipped to you upon request; however, you will be responsible for any associated shipping and packaging costs. Our engineers will work with you regarding tool compatibility with your equipment if you're unsure.

Can you run different colors of the same material?

Yes, multiple colors can be run even on the same order! When running multiple colors on the same order, a purge charge will be added.

Additional Xometry Molding Services

Compression Molding Service

Insert Molding Service

Overmolding Service

Metal Injection Molding Service

Liquid Silicone Rubber Molding

Gas Assist Injection Molding

Medical Injection Molding Service

Large Part Injection Molding Service

Xometry Plastic Injection Molding Case Studies

Case Study: Combating COVID-19 with a Contactless, AI-Based Thermal Imaging Device