Custom Online Acrylic Molding Service by Xometry

Get custom acrylic molded production parts in as few as five business days. We provide expert engineering reviews. Dozens of materials and finishes are available. ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified.

Xometry offers world-class injection molding services that include both on-demand prototypes and production molding. We can process a wide range of materials including acrylic and can achieve polished surface finishes for optical applications. Xometry is ISO 9001:2015 certified, which means that your products will meet internationally recognized quality standards. In addition, we offer fast turnaround times due to our extensive range of manufacturing partners.

Acrylic Material Properties

Table 1 below lists some common material properties of standard acrylic:

Chemical Formula | (C5O2H8)n | PMMA - Poly(methyl methacrylate) |

Transmittance (%) | 90.3 | Measure of acrylic's ability to transmit light. |

UV Transmittance (%) | 77.4 | Measure of how much UV radiation acrylic lets through. |

Density (g/cm3) | 1 | Defines the compactness of the molecules within the acrylic. |

Vicat Softening Point (°C) | 101 | The point at which acrylic begins to lose its structural integrity. I.e., it defines the resistance to deformation at elevated temperatures. |

Ultimate Tensile Strength (MPa) | 179 | Defines the point at which acrylic will fail when loaded in pure tension. |

Elongation at Break (%) | 10.10 | The increase in length at the point of tensile failure. |

Flexural Modulus (GPa) | 2.88 | A measure of the stiffness of acrylic, i.e., its resistance to bending. |

Flexural Yield Strength (MPa) | 103 | The stress at which acrylic will experience permanent deformation when exposed to bending loads. |

Izod Impact (Notched) (J/cm) | 0.303 | The impact strength of acrylic. To be used as a comparative value. |

Hardness (Rockwell R) | 69 | The hardness of acrylic is measured on the Rockwell R scale for comparative purposes. |

Max Service Temperature (Air) (°C) | 86.8 | The maximum recommended operating temperature of acrylic in the air is to prevent failures. |

Melting Temperature (°C) | 227 | The temperature at which acrylic transfers into a molten or liquid state. |

Table Credit: https://matweb.com/

Advantages of Acrylic Molding

Acrylic has excellent optical properties and is weather-resistant, lightweight, and shatter-resistant. This is why it is often used as a glass substitute. Acrylic can also be more easily processed into various shapes using injection molding, which is not practical with glass. For more information see below:

- Shatter Resistance

- Exceptional Optical Clarity

- First-Rate Weatherability and Resistance to Sunlight

- Excellent Processability

- Quality Light Transmission

- Rigid, With Good Impact Resistance

- Multi-Color

- Lightweight

Shatter Resistance

Shatter resistance refers to a material's resistance to sudden, catastrophic, brittle fracture. Acrylic is an excellent alternative to glass in this regard as it is more durable and has significantly higher shatter resistance. In addition, it does not create shards with dangerously sharp edges when broken. This makes acrylic a good option where safety is a concern.

Exceptional Optical Clarity

Optical clarity refers to how well a material allows light to pass through it. A higher value relates to higher light transmissibility. Acrylic has a transmittance value of 90.3% which means that it only blocks 9.7% of light. This makes it an excellent alternative to glass, which has a comparable transmittance rate of up to 90%.

First-Rate Weatherability and Resistance to Sunlight

Acrylic is highly resistant to the effects of weather and sunlight. Unlike most plastics, which have poor UV resistance, acrylic is relatively unaffected by UV radiation. This means it can be used as a replacement for glass and other transparent plastics like transparent PVC, which tends to turn yellow when exposed to UV radiation.

Excellent Processability

Unlike glass, acrylic can be easily formed using techniques like injection molding and can be formed into a wide variety of shapes without having to undergo significant post-processing. This means it can be molded into complex components that can be used for scientific analytics equipment.

Quality Light Transmission

A material can be considered a quality light transmitter if the light does not scatter excessively when passing through. The molecular structure of acrylic consists of randomly distributed macromolecules as well as having very few impurities. This reduces the amount of scattering and distortion created when light passes through it compared to materials with a more regular crystalline structure.

Rigid, With Good Impact Resistance

Acrylic has high flexural strength as well as high impact strength. This means it can withstand impact loads that would shatter materials like glass. Its high impact resistance also means it can be thinner than glass but have similar or better strength.

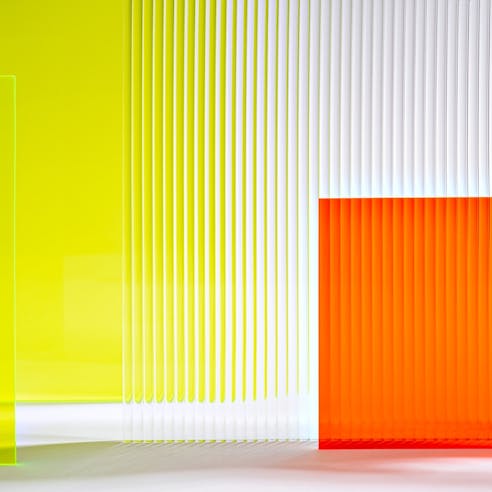

Multi-Color

Despite acrylic's optical clarity, it can also be tinted to be semi-transparent in a range of colors or be completely opaque. This makes it ideal for applications in which aesthetics are important.

Lightweight

Acrylic has a density of 1.17 g/cm3, making it very lightweight when compared to glass which has a density of around 2.5 g/cm3. Coupled with its superior shatter resistance, thinner acrylic sheets can be used to achieve the same strength as glass, further reducing overall weight.

Need custom acrylic molded parts?

Acrylic Injection Molding Applications

Acrylic has a wide range of applications due to its optical clarity, weather resistance, and durability. Listed below are some common applications of acrylic for various components of these products:

- Signs and Sign Holders

- Retail Displays and Shelves

- Lenses

- Medical Testing Equipment

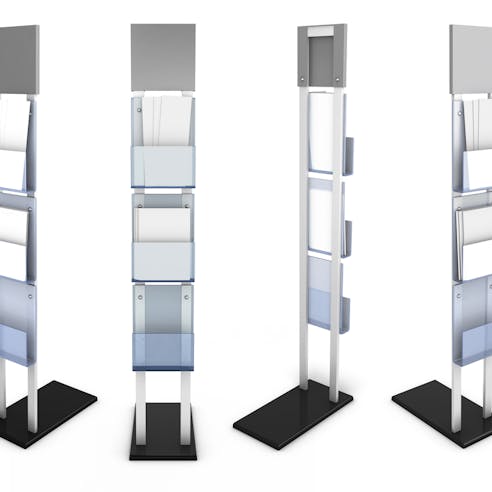

- Brochure Holders

- Skylights

- TV Screens

- Submarine Windows and Aquarium Tanks

Signs and Sign Holders

The optical clarity and availability in multiple colors make acrylic an excellent option for signs and sign holders, especially in outdoor applications where other plastics tend to fade or break down over time. This is due to acrylic's excellent weather and UV resistance.

Retail Displays and Shelves

Retail applications require clear, unobstructed views of a product, as such acrylic is often used for displays and shelves as it is clear and can be used in structural applications due to its durability. It can also be produced in a range of colors to make displays more visually appealing.

Lenses

Due to acrylic's excellent optical characteristics such as quality light transmissibility and optical clarity, it can be used for lenses in applications such as eyeglasses and microscope focal lenses.

Medical Testing Equipment

Many labs perform testing on devices known as a “lab on a chip.” These devices can precisely replicate the behaviors of biological processes with almost no moving parts. They are often produced from clear acrylic, so scientists can study real-time biological phenomena with a microscope.

Brochure Holders

Brochures are specifically designed to catch the attention of potential customers, and if a brochure holder obstructs part of the design, this will negate the effect. In this case, clear acrylic brochure holders are ideal.

Skylights

Skylights are used to direct sunlight into a building to provide natural lighting during the day. They are often domed so that the light can be directed to a larger area in the room. Acrylic is ideal for this application as it can be easily molded into complex shapes and also does not degrade when exposed to sunlight.

TV Screens

TV screens can be easily scratched and damaged, especially if they are used in public areas. In these cases, acrylic screen protectors provide protection against normal wear and tear as well as deliberate damage while allowing light from the screen to pass through with no distortion.

Submarine Windows and Aquarium Tanks

Submarine and aquarium windows need to be able to withstand high pressures, afford excellent clarity, and must be resistant to seawater. Acrylic is often used for this application as it has all the required properties with the added benefit of being shatter-resistant and lightweight. Large hemispherical domes can be produced for submarines to optimize pressure resistance.

Why Choose Xometry for Acrylic Molding?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

We are ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified.