TPU 3D Printing Service

Get instant online quotes on TPU parts. Free shipping on all US orders. ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified.

About TPU 3D Printing

Most 3D printed plastic materials take the form of rigid thermoplastics, which limits the potential for prototyping in flexible materials. TPU bridges the gap by allowing for a thermosetting polyurethane to be 3D printed. As is the case with any elastomeric polymer, 3D printing with TPU has excellent resilience, impact resistance, and general toughness.

TPU (thermoplastic polyurethane) for Multi Jet Fusion printing is a thermoset polyurethane exclusive to MJF printers. 3D-printed TPU plastic has excellent flexibility, shock absorption, and elasticity. These properties make this material useful in a range of industries for automotive parts, sports equipment, and medical devices. It is also ideal for complex flexible lattice components.

3D Printed TPU at a Glance

| Common Applications | Advantages | Disadvantages | Typical Lead Time | Price | Minimum Feature Size | Tolerances |

|---|---|---|---|---|---|---|

Common Applications Sports footwear, orthopedic models, cable strain reliefs | Advantages UV resistance, hydrolysis resistance | Disadvantages Sensitive to humidity | Typical Lead Time 5 Days | Price Moderate | Minimum Feature Size 0.020" (0.508 mm) or greater | Tolerances |

Applies to US-based production only.

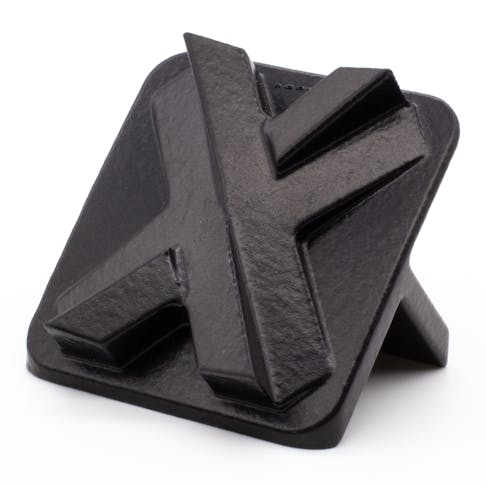

MJF TPU 88A

3D printing in TPU 88A is ideal for applications that require flexibility and resilience. Its elastomeric nature allows parts to deform to a high degree and then return to their original shape. Applications can include soft robot grippers, complex shock-absorbing shoe soles, or flexible bellows.

MJF TPU 88A Properties

| Tensile Strength (MPa) | Elongation at Break (%) | Hardness (Shore A) | Melting Temperature (℃) | Glass Transition (℃) | Data Sheet |

|---|---|---|---|---|---|

Tensile Strength (MPa) 9 | Elongation at Break (%) 220 | Hardness (Shore A) 88 | Melting Temperature (℃) 120-150 | Glass Transition (℃) -48 | Data Sheet |

Applies to US-based production only.

TPU 88A Finishing Options

Parts are removed and de-powdered with a grit-blasting process. MJF parts have a smooth matte surface finish straight off the machine.

Parts are submerged in a heated dye solution to produce a uniform matte black surface finish.

An automated post-processing technology (AMT PostPro3D) is used to achieve a high-quality surface finish. Vapor smoothing brings most surfaces from matte to semi-gloss. Vapor smoothing also seals the surface, enhances mechanical properties, and provides a consistent cosmetic finish for production. Vapor-smoothing can also be performed on non-dyed parts. Click here to learn more about vapor smoothing.

Custom surface finishes like painting can also be requested.