Rapid Machining Services by Xometry

High quality rapid machined prototypes and production parts in days | AS9100D | ISO 9001:2015 | ISO 13485 | IATF 16949:2016 | ITAR Registered

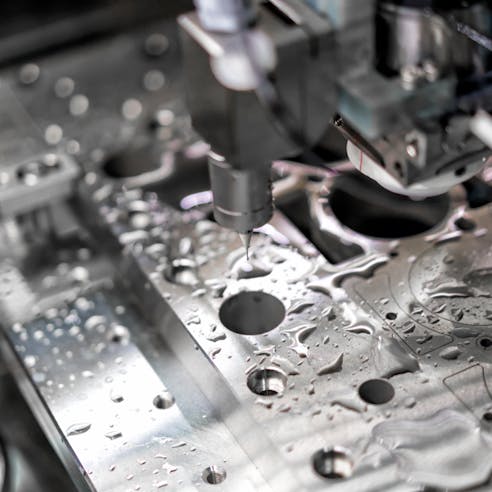

Xometry offers high-quality rapid machining services to manufacture precision parts with a quick turnaround time. Rapid machining uses advanced CNC (computer numerical control) machines to enable the quick production of custom components. The manufacturing process is designed to be efficient and prioritize speed of delivery to provide on-demand manufacturing. However, due to the capabilities of the machines and the quality processes, each component is still made with high precision. Rapid machining services allow fast prototyping as well as other quick turnaround requests for high-quality parts.

Rapid Machining Process

A rapid machining project will follow a defined process to ensure the production of a high-quality component. The project begins with CAD design. Our team of experts works together to optimize the CAD design to allow faster and cheaper machining. Once the CAD design has been optimized for machining, we select the best material for the purpose. This is primarily a function of the component’s intended application and the cost but is also influenced by factors such as the component’s geometry. For rapid machining, materials that are easily machinable are prioritized. This could be a range of plastics or metals, which cover an incredibly wide band of costs and properties.

Before getting started on manufacturing the part, the CNC programming takes place. Each step that the CNC machine will perform is provided, with details such as the tool to use, the geometry of the tool movement, the feeds and speeds, and the tool offset. This critical task of CNC programming is made easier and quicker with CAM (computer-aided manufacturing) software. For rapid machining, specific use of high-speed roughing approaches and high-torque machines are employed. With the CNC programming complete, the machining of the selected material begins. Finishing processes are then done to ensure a high-quality final product and carry out further machining, grinding, boring, or polishing for high-precision tolerances.

Materials and Manufacturing Capabilities for Rapid Machining

Rapid machining is incredibly versatile and has multiple material and manufacturing capabilities. The materials that can be used range from plastics to various ferrous and non-ferrous metals. A common material is aluminum, as it is relatively lightweight, corrosion-resistant, and easy to machine. Another common family of materials is alloy steels. These are different grades of steel with other alloying elements added to promote certain properties such as: high tensile strength, improved corrosion resistance, and better machinability. These alloy steel components are used in a wide variety of industries, including: aerospace, automotive, and sporting goods. Another popular metal for machining is brass. Its corrosion resistance makes it ideal for components in valves and other plumbing applications.

Xometry utilizes advanced CNC machines with multi-axis capabilities. Our high-quality equipment is capable of producing complex parts with high precision and tight tolerances. CAM software enables the programming of the machine to be highly efficient, with optimized tool paths. Advanced techniques enabled by the software are also employed—measuring tool loads and deviations to produce parts more consistently and with better finishes and precision.

Advantages of Rapid Machining

Rapid machining services provide a number of key advantages, including:

- Time-Saving

- Cost Effective

- Design Validation

- Reduced Lead Times

- Flexibility

Time-Saving

Rapid machining is designed to be efficient, from receiving the 3D model of the component to completion of the machined and finished item. The approach to material selection aims to reduce the time required to produce the part.

Cost Effective

For limited runs of custom parts, rapid machining is cost-effective. Using CNC machines generally reduces labor costs for machining parts. Also, compared to other rapid manufacturing processes such as selective laser sintering (additive manufacturing), the cost for a mechanically strong item via machining is significantly lower.

Design Validation

Using a precise, machined component reveals the efficacy/accuracy of the design, often in the final intended material. This allows for practical product testing in the desired application, resulting in clear and accurate feedback on the design of the part. Any design changes can be rapidly translated into an updated version and manufactured for the next iteration of testing.

Reduced Lead Times

Rapid machining focuses on reducing the lead time from the 3D model to delivery. Each step in the process is automated where possible, including key quality checks and human interfaces where it matters. The CNC machines we use are also specifically designed for high material removal rates and are highly automated for efficiency and speed. These factors combine to deliver a lead time for a manufactured component counted in days rather than weeks.

Flexibility

CNC machining is incredibly flexible, it can handle a wide variety of materials and can use many different tools with multi-axis machining to manufacture complex geometries. This means that rapid machining can be used for a vast range of part designs and applications.

Ready to get started on your rapid machining quote?

Disadvantages of Rapid Machining

Rapid machining fulfills a specific purpose in the manufacture of bespoke components with a short lead time. Therefore, there are some limitations and constraints on what is possible with rapid machining, including:

- Large Quantity Costs

- Lead Time for Complex Designs

- Material Limitations

Large Quantity Costs

Rapid machining is optimized around small unit numbers. The CNC machines and tools employed to manufacture rapidly will be relatively more expensive than standard machining equipment. This means that the cost per part will be higher with rapid machining. This has a limited impact on a few custom parts in the design development phase. But for a production run of a large quantity of identical parts, rapid machining is simply not cost-effective compared to more standard CNC machining processes.

Lead Time for Complex Designs

Complex designs may extend the lead time significantly. The design may need significant effort to make it compatible with good practices for CNC machining, or else have challenging features that need to be adjusted to make fabrication by machining possible. For the fabrication, complex designs may need more tool changes and setup changes. Also, smaller tools with lower material removal rates may be required. These considerations add time to the delivery.

Material Limitations

Rapid machining may not be able to process some materials. In routine manufacturing, the toughest metal grades may be difficult to machine, such that an experienced operator may need to manually machine the material with low feeds and speeds. Such materials are not well-suited to rapid machining. Material selection prioritizes materials that are easy to machine, allowing high material removal rates and a high level of automation.

Rapid Machining Industries

The versatility, precision, and speed of rapid machining make its application valuable to a range of industries. These industries are listed below:

- Aerospace

- Automotive

- Medical

- Electronics

- Consumer Goods

Aerospace

The aerospace industry uses non-standard parts that are developed for a specific purpose and set of uncommon conditions. This leads to the need for many custom components, which also need to comply with the highest quality standards. Exotic materials are commonly used in the aerospace industry. Rapid machining is capable of providing complex parts with a reduced lead time and from a variety of materials.

Automotive

Product development in the automotive sector requires the design of new parts regularly. Time is key in model update cycles, and rapid machining assists in accelerating the process to the final design. This can be relevant in various sectors of automotive manufacturing, including interiors and items like mirrors and steering apparatus.

Medical

Rapid machining is a great match with the medical industry as it is well suited to making small volumes of highly precise components with a quick turnaround. It also works with biocompatible materials such as plastic PEEK (polyetheretherketone) or titanium. This makes rapid machining the ideal solution to create implants and other devices according to unique patient needs.

Electronics

There are few industries globally that develop at the pace of the electronics industry. Advances in technology drive the development of new devices constantly. These devices require machined parts such as cases, heat sinks, and connectors. Rapid machining allows the development process of these devices to progress through multiple design iterations, arriving at an optimized design before mass manufacture.

Consumer Goods

The consumer goods industry is incredibly broad but includes many different complex items such as watches, spectacles, sports equipment, and appliances. These items need machined components, often optimized for high quality but at the lowest cost to manufacture. This may need several iterations on individual parts to make them stronger but with less material. Rapid machining allows these iterations to be carried out on a wide variety of different parts, whether cases, bodies, hinges, or screws (for example).

Applications of Rapid Machining

Rapid machining has various applications, including:

- Prototyping

- Tooling

- End-Use Parts

- Low-Volume Production

Prototyping

When developing a new product, there will inevitably be some iterations to the design. Manufacturing a prototype is a valuable approach to finalizing the design, as the prototype can be tested. This helps to identify and rectify any flaws before mass production.

Tooling

Rapid machining can be used to manufacture tools and molds for parts production, enabling rapid tooling. This is another way that rapid machining supports prototyping. Even if the prototype cannot be machined, the tool or mold to fabricate the prototype can be made via rapid machining. An example is a die for injection molding.

End-Use Parts

Rapid-machining parts are high quality and high precision. There is no inferiority with parts manufactured via this process. So long as the part has been machined from the required material for the end use, it can be put directly into service. Rapid machining of end-use parts can also be applied when an unexpected breakdown has occurred on a critical piece of equipment, and logistics or stock of the necessary part has a longer lead time than simply fabricating it locally.

Low-Volume Production

Rapid machining is cost-effective for a low volume of production parts. An example is if a certain spare part is out of regular production, but there is still an occasional need for the spare. Rather than stopping a large-volume run on other machines to tool up for a small run of the specific spare, running a low-volume production at a rapid machining service supplier is a viable option. Rapid machining can produce the parts to the production specification and tolerances.

Alternative Manufacturing Solutions

Xometry offers various alternative manufacturing options for component fabrication. A few of the most relevant ones are explained below:

- 3D Printing

- CNC Machining

- Injection Molding

- Laser Cutting

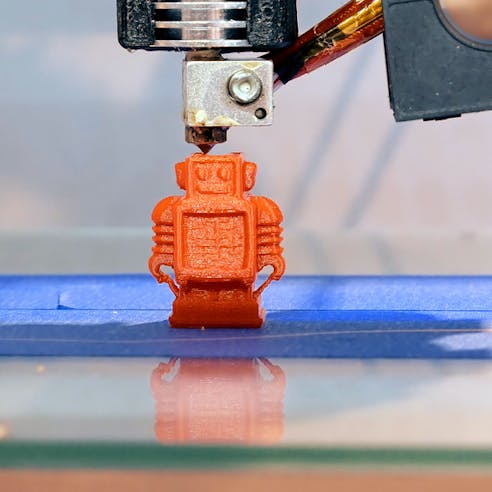

- 3D Printing: 3D printing is a rapidly growing field that already incorporates multiple ways of manufacturing. It is essentially additive manufacturing, in which parts are created by adding material in a controlled manner. (Rapid machining is, of course, an example of subtractive manufacturing, in which material is removed to arrive at the final geometry.) 3D printing methods are the most advanced, accessible, and cost-effective for polymeric materials (plastics), but there are a number of commercialized technologies for 3D printing metals. Selective laser sintering (SLS) is one, in which a laser is directed onto a bed of metal powder in order to sinter a layer of the powder into the main metal body. 3D printing of metals is currently expensive and is limited to small component sizes. But as the technologies mature, it is expected to become more widely used. Complex shapes can be fabricated almost directly from the 3D model of the desired part in a matter of hours or days.

- CNC Machining: CNC machining is very similar to rapid machining but uses standard machines, equipment, and processes that are less focused on speed of delivery. Standard CNC machines are still incredibly versatile and are able to fabricate precise and repeatable parts with a high level of automation. Depending on the complexity of the part, CNC machining may be used for only some of the machining, with manual machining carried out for other aspects.

- Injection Molding: Injection molding is typically used to fabricate plastic parts. Rapid injection molding prioritizes small quantities of parts with a fast turnaround. It is an inexpensive manufacturing method used for many small consumer parts. However, it is limited in the materials that can be used (typically plastics rather than metals) and in the size of the parts that can be made.

- Laser Cutting: Laser cutting is able to produce precise shapes from sheets, usually at a high speed. There is a limitation on the thickness of the sheet that can be used, as the laser has a specific focal point with high optical energy for cutting. Laser cutting is typically carried out in a single dimension. It can be applied to a range of materials, but there are some materials that cannot be laser-cut. These materials could be too reflective, release harmful fumes, or be flammable.

Xometry's Quality Assurance for Rapid Machining

Xometry is committed to quality, even for fast-turnaround parts. Our quality management system is ISO certified, compliant with ISO 9001, ISO 13485, and AS9100D. These certifications ensure that rigorous quality control measures are in place, with traceability of material and processes. Inspections are added at key points of the manufacturing process to ensure the highest-quality outcome. Xometry has dedicated quality assurance laboratories in different locations around the world that can check parts when requested.

Why Choose Xometry for Rapid Machining Services?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get started with our easy-to-use platform and let our experts take care of managing the project from locating the right manufacturing partner to delivery logistics.

Vetted Network

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.