Acrylic Fabrication Services

High quality custom acrylic fabricated production parts in days | AS9100D | ISO 9001:2015 | ISO 13485 | IATF 16949:2016 | ITAR Registered

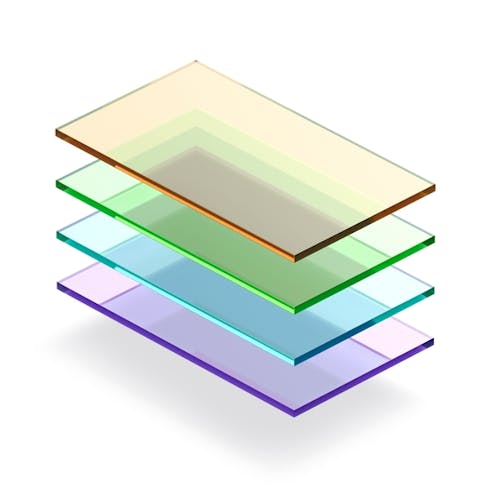

Acrylic is an optically clear, UV-resistant, BPA-free thermoplastic that can be purchased in various grades. It is also known by the trade names Plexiglas® and Perspex®. Acrylic's chemical name is PMMA (poly methyl methacrylate) and it can be manufactured in either cast or extruded variants. Cast acrylic tends to have improved scratch resistance whereas extruded acrylic has improved chemical resistance. Xometry offers a custom acrylic fabrication service that includes but is not limited to precision cutting, CNC machining, laser engraving, and bonding. We ensure rigorous quality control processes are followed through the fabrication process to ensure your parts meet the highest quality standards.

Acrylic Fabrication Process

When embarking on an acrylic fabrication project, it is important to follow a structured approach that begins with the initial design consultation. This includes material selection and DFM (design for manufacturing) analysis to ensure your design can be manufactured as cheaply as possible without compromising quality or functionality. There are two main variants of acrylic namely, cast or extruded. However, many variants can include different additives to further enhance specific properties. Xometry can help you navigate the complex landscape of different materials to find the one most suitable for your application. In some cases, acrylic might not even be the optimal material, which is why it's important to thoroughly vet the material before proceeding. Next, the part can be fabricated. Acrylic can be fabricated using a wide range of techniques, some of the most common of which are listed below:

- CNC Machining: Acrylic can be easily machined, provided tooling is kept sharp. However, it's important to limit any potential stress concentrations due to the brittleness of acrylic. It is also recommended to avoid tapered threads as these introduce significant stress to the material.

- Solvent Bonding: Acrylic can be bonded by making use of solvent-based adhesives. These adhesives will soften the acrylic and weld the different components together. The bonded area should be clamped while the adhesive dries.

- Forming & Bending: Acrylic must be heated just past its softening temperature to form it. Attempting to form without heat will result in the acrylic breaking. Making small bends can be done with a strip heater to evenly heat the bend area. The acrylic must only be heated to the point where it begins to soften. It has a low melting temperature, so care must be taken.

- Cutting: Acrylic can be cut with a range of different tools such as circular saws, jigsaws, plastic scoring blades, band saws, laser cutters, and table saws. High-tooth-count cutting tools must be used to prevent chipping and breaking the acrylic parts.

Various finishing techniques are available with acrylic and can include abrasive or flame polishing, laser engraving, and texturing. Throughout this fabrication and finishing process, it is important to follow rigorous quality control processes to ensure the resulting product meets the highest quality standards.

Advantages of Acrylic Fabrication

Acrylic is used in a large number of applications due to its many advantages, some of which are listed below:

- Versatility

- Clarity

- Durability

- Light Weight

- UV Resistance

- BPA Free

Versatility

Acrylic can be formed into many different shapes using a range of manufacturing methods. This makes it more versatile than glass, which is significantly more difficult to work with as it needs to be worked in its molten form.

Clarity

Acrylic has an optical clarity of between 89 and 92 %. Common grades of glass, on the other hand, can have optical clarity anywhere from 80 to 90 %, making acrylic generally better at transmitting light. Acrylic is often used for lenses in scientific equipment due to its clarity.

Durability

Acrylic is brittle when compared to other plastics, but it is not as brittle as glass. This makes acrylic ideal for windows on heavy equipment or in public spaces as it can withstand higher impact loads. It also does not produce dangerous sharp edges if it does eventually break.

Light Weight

Acrylic has a density of 1.17 g/cm3 which is significantly lighter than glass at a density of between 2.2 to 3.7 g/cm3. Thinner sheets of acrylic can provide better strength than standard-thickness panes of glass. Acrylic is therefore an ideal replacement for glass if low weight is required, as in the aerospace industry.

UV Resistance

Some clear plastics will degrade and become yellow when exposed to UV (ultraviolet) radiation for long periods. Whereas acrylic is resistant to UV radiation, meaning it can be used as a replacement for glass without degrading over time.

BPA Free

Acrylic does not release Bisphenol A (BPA), which is a chemical that has been proven to be harmful to humans. This is why acrylic is an ideal replacement for polycarbonate in applications in which polycarbonate has the potential for unsafely releasing BPA.

Ready to get started on your acrylic fabrication quote?

Disadvantages of Acrylic Fabrication

Acrylic has some limitations that must be considered before selecting it for your project. Some key limitations are listed below:

- Susceptibility to Scratches

- Less Impact Resistance Than Many Plastics

- Limited Resistance to Certain Chemicals

- Poor Thermal Resistance

Susceptibility to Scratches

One major disadvantage of acrylic is how easily it can be scratched because it is soft and has low wear resistance. While acrylic can be an attractive alternative to glass, its poor resistance to scratches means it will lose its optical clarity over time. Whereas, glass is significantly more resistant to scratches. Acrylic can, however, be polished to remove any scratches.

Less Impact Resistance Than Many Plastics

While acrylic can be considered to be tougher than glass, it is not tough when compared to other plastics and is generally considered to be brittle. If light weight and increased toughness are required, then it would be better to use a material like polycarbonate.

Limited Resistance to Certain Chemicals

While acrylic is resistant to alkalis and detergents, it shows poor resistance to esters, ketones, aromatic hydrocarbons, high-concentration acids, and chlorinated hydrocarbons to name a few. As such, its use must be carefully considered when it is to be exposed to harsh chemicals. Glass is resistant to a wide array of chemicals at higher temperatures.

Poor Thermal Resistance

Acrylic has poor thermal resistance in terms of both high and low temperatures. It has a recommended maximum continuous operating temperature of between 65 °C and 95 °C while it starts exhibiting increasing brittle behavior at temperatures as high as 9.5 °C.

Industries Served and Applications of Acrylic Fabrication

Acrylic is a popular material in a range of industries primarily due to its optical clarity, low weight, and resistance to UV radiation. Listed below are some key industries and applications of acrylic:

- Retail

- Advertising

- Healthcare

- Architecture

- Electronics

- Scientific Equipment

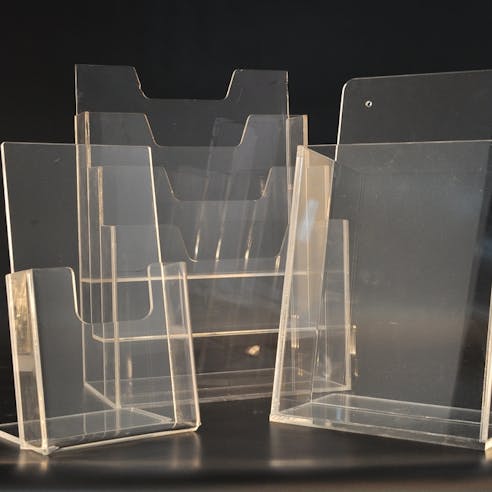

Retail

Acrylic is often used for display cases in retail spaces. This is because of their excellent optical clarity that affords unimpeded views of the products enclosed within. Its low weight and versatility make it easy to move and modify as required.

Advertising

Acrylic is less susceptible to UV radiation than other plastics. This longevity makes it ideal for long-term signage that won’t degrade and discolor over time, keeping advertisements as colorful and crisp as they were originally intended.

Healthcare

Acrylic has a wide range of uses in the medical industry, primarily due to its optical clarity, biocompatibility, and low weight. Typical examples can include incubators, tubing connectors, Petri dishes, and LOCs (Lab on a Chip).

Architecture

Acrylic’s UV resistance, optical clarity, and toughness make it ideal for architectural applications. For example, acrylic sheets can be used for windows, colorful facades, balcony guards, and skylights.

Electronics

Acrylic is the ideal material for clear electronic casings and screen covers. It is also transparent to infrared light making it an ideal guard for infrared transmitters and receivers like those typically used for remote-control applications.

Scientific Equipment

Acrylic is widely used in the manufacture of scientific equipment and apparatus. Its optical clarity, non-reactivity to biological agents, and ease of manufacture make it ideal for complex biological test chips and focusing lenses.

Alternatives to Acrylic Fabrication

While acrylic has many beneficial properties, it might not always be the ideal material for your application. Listed below are some common alternatives:

- Polycarbonate

- PVC

- PETG

- ABS

- PP

Polycarbonate

Polycarbonate is optically clear, however, its clarity is slightly lower than that of acrylic at between 86 % to 92 %. However, polycarbonate is significantly stronger than acrylic and can be used in applications that require enhanced resistance to impact loads.

PVC

PVC (polyvinyl chloride) has improved chemical resistance and higher toughness when compared to acrylic. And while clear PVC is available, some grades will discolor and become opaque when exposed to long-term UV radiation.

PETG

PETG (polyethylene glycol) is cheaper and significantly tougher than acrylic and is better suited to applications that will see rough use. It must also be noted that PETG is available in transparent grades with light transmission comparable to acrylic.

ABS

ABS (acrylonitrile butadiene styrene) is a wear-resistant plastic with excellent toughness and high-temperature resistance. ABS does come in transparent grades, often referred to as MABS (methyl methacrylate acrylonitrile butadiene styrene), with a light transmission of 86 %.

PP

Polypropylene (PP) has high mechanical strength, chemical resistance, and thermal resistance while also being relatively low cost. Polypropylene also has good moisture resistance, making it ideal for food packaging applications. Special grades of transparent polypropylene are also available.

Copyright and Trademark Notices

- Plexiglas® is a registered trademark of Röhm, the company owned by the German inventor of PLEXIGLAS®, Otto Röhm.

- Perspex® is a trademark of Perspex Distribution Ltd

Why Choose Xometry for Acrylic Fabrication Services?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get started with our easy-to-use platform and let our experts take care of managing the project from locating the right manufacturing partner to delivery logistics.

Vetted Network

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.