Polycarbonate Laser Cutting by Xometry

Xometry offers the highest quality polycarbonate laser cutting services and can assist in the production of parts with intricate and complex geometries and excellent surface finishes.

Polycarbonate laser cutting requires careful execution under specific conditions in order to be successful. Cutting quality and results depend heavily on your choice of laser. A CO2 laser is the recommended choice for the common industrial plastic known as polycarbonate. Laser-cut sheets of polycarbonate get used in signage and displays; the technology allows you to create intricate shapes, letters, and logos. Another significant application lies in prototyping and product development. A polycarbonate laser cutting service can enable you to bring your ideas to life quickly in the form of accurate prototypes for testing and validation.

At Xometry, we strive to deliver exceptional polycarbonate laser cutting services, providing our customers with high-quality solutions for their polycarbonate cutting needs. You can expect exceptional results thanks to our commitment to precision and efficiency.

What Is Polycarbonate Laser Cutting?

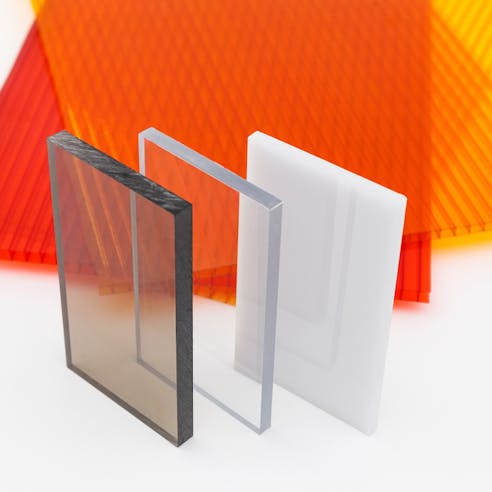

Polycarbonate laser cutting utilizes laser technology to precisely cut and shape polycarbonate sheets or workpieces. Polycarbonate, often referred to as PC, is a transparent thermoplastic material with useful physical properties such as: impact resistance, transparency, and heat resistance.

During the laser cutting process, a high-powered laser beam is directed onto the polycarbonate material, causing localized heating and melting. The laser beam follows a predetermined path guided by computer-controlled software, allowing for intricate and precise cuts to be made on the polycarbonate sheet.

Laser Processes for Polycarbonate

Polycarbonate can accept a few different laser processes:

- Laser Cutting

- Laser Engraving

Laser Cutting

Laser cutting is the process of using a laser beam to cut through the polycarbonate material, creating precise and clean edges. It is commonly used to produce intricate shapes, patterns, and components. Many types are available, but CO2 laser cutters are the most suitable for cutting PC. Examples of applications for laser-cut polycarbonate include: transparent windows for greenhouses, safety windows, optical components, lenses, and diffusers used in lighting fixtures or optical instruments.

Laser Engraving

When a laser engraves polycarbonate, it removes a small portion of the material's surface to create recessed or raised designs. This is usually done using a fiber laser cutter. The material is typically engraved for decorative or other aesthetic purposes. Examples of applications for laser-engraved polycarbonate include: custom nameplates, signs, plaques with engraved text, logos, graphics, engraved keychains, custom-designed phone cases, and decorative panels used in architectural or interior design applications.

Advantages of Laser Cutting Polycarbonate

Lasers offer several advantages over traditional polycarbonate cutting methods. Here are some key advantages:

- High Precision

- Clean Edges

- Versatility

- No Physical Contact

- Efficiency and Speed

- Flexibility in Design Changes

High Precision

Lasers cut with exceptional precision and accuracy. The laser beam is controlled by computer software that directs intricate and detailed cuts with tight tolerances. This precision is particularly apparent when working with complex shapes, fine details, or small parts.

Clean Edges

Laser cutting produces clean and smooth edges on polycarbonate. The laser beam’s intense heat melts and vaporizes polymer material, leaving behind nothing but a clean, precise edge. This process is accurate enough to eliminate the need for additional finishing processes — a fact that’s doubly valuable when both aesthetics and tight tolerances are important.

Versatility

Laser cutting is a versatile process that can handle different sizes of polycarbonate sheets. It allows for the cutting of intricate shapes, curves, and angles, giving you lots of design flexibility.

No Physical Contact

Laser cutting is a non-contact process, which means there is no direct physical contact between the cutting tool and the material. This eliminates the risk of friction-induced material deformation, warping, or other damage. It also minimizes the chances of contamination or scratching on the polycarbonate surface. As a bonus, the tool (the laser cutting head) does not need to be serviced or replaced nearly as often as physical cutting tools.

Efficiency and Speed

Laser cutting is a speedy and highly efficient process. Lasers can cut through polycarbonate material swiftly, improving your production times and productivity. The automated nature of laser cutting further enhances efficiency by reducing manual labor and setup time.

Flexibility in Design Changes

Laser cutting offers flexibility when it comes to design changes. Since the cutting path is controlled by software, modifications to the design can easily be implemented without the need for complex tooling or additional setups. This makes it ideal for prototyping or projects with frequent design iterations.

Disadvantages of Laser Cutting Polycarbonate

Laser cutting polycarbonate does have a few disadvantages associated with it:

- Sensitive to Scratches

- Thermal Expansion

- Yellow Discoloration

- Burrs and Imperfections

- Thickness Limitations

- Calibration and Speed Considerations

Sensitive to Scratches

Polycarbonate is more susceptible to scratching than glass or similar plastics. This can affect the visual clarity and overall aesthetics of the cut parts.

Thermal Expansion

Polycarbonate has a relatively high coefficient of thermal expansion. It expands and contracts significantly with temperature changes. Lasers are hot, so they can induce localized heating in the material and potentially cause it to expand unevenly. This can result in dimensional changes, warping, or distortion in the cut pieces.

Yellow Discoloration

Laser cutting can cause polycarbonate to yellow along newly-cut edges. This is due to the buildup of melted decomposition products created by the laser's heat, resulting in an aesthetically imperfect finish.

Burrs and Imperfections

The melted polycarbonate can harden and leave burrs or imperfections along the cut edges, which may require additional post-processing or smoothing to achieve the desired finish.

Thickness Limitations

Only polycarbonate sheets of appropriate thickness can accept laser cutting. The cut depth is limited, making it less suitable for very thick polycarbonate sheets. Ideally, the polycarbonate sheets being cut or engraved should not be thicker than 3 mm.

Calibration and Speed Considerations

Proper calibration and cutting speed are crucial for achieving clean and precise cuts when laser cutting polycarbonate sheets. Finding the optimal balance may require some experimentation.

In need of custom polycarbonate laser cutting services?

Applications of Laser Cutting Polycarbonate

Laser-cut polycarbonate is valuable in various industries and applications, including:

- Anti-Ballistic Panels

- Safety Glasses

- Automotive Parts

- Room Dividers

- Electronics

- Building Applications

Anti-Ballistic Panels

Laser-cut polycarbonate sheets find their way into anti-ballistic panels used in bulletproof barriers or shields. Bulletproof polycarbonate sheets are specifically engineered to withstand the impact of bullets without fracturing or breaking. They are common components of bulletproof police shields, security installations, banking facilities, and jewelry stores. Though the sheets resist bullet impacts, they can be cut into any shape using laser power, and they don’t lose strength or ballistic resilience in the process.

Safety Glasses

Laser cutting is employed to shape polycarbonate safety glasses with precise dimensions and contours. The laser creates clean and smooth edges, ensuring a comfortable fit for the wearer and maintaining the optical clarity of the material.

Automotive Parts

Laser-cut polycarbonate is used to create various automotive components like interior panels, light covers, and displays. Automotive manufacturers appreciate the process because it efficiently shapes parts to precise dimensions for seamless assembly, even if they come in precise and intricate shapes.

Room Dividers

Polycarbonate sheets can be laser cut to form room dividers with intricate patterns or customized designs. The clean cuts turn into visually appealing dividers that provide both transparency and privacy.

Electronics

Laser-cutting is applied in the manufacture of electronic components, including display screens, light guides, and protective covers. The resulting parts are both precise and accurate, ensuring the proper fit of components and maintaining the optical properties of the material.

Building Applications

Laser-cut polycarbonate sheets are used in building applications such as architectural panels, skylights, glazing, and decorative elements. Laser cutting allows for the creation of complex shapes, patterns, and textures, enhancing the aesthetic appeal of buildings while maintaining the material's transparency and durability.

Alternatives to Laser Cutting Polycarbonate

There are several alternatives to laser cutting when it comes to working with polycarbonate. Some of the common options include:

- Waterjet Cutting

- Abrasive Waterjet Cutting

- CNC Routing

- Saw Cutting

- Waterjet Cutting: Waterjet cutting uses a high-pressure stream of water to cut material. Water-only waterjet cutting is effective for cutting polycarbonate sheets up to 0.032 inches thick and can produce precise and clean cuts.

- Abrasive Waterjet Cutting: Abrasive waterjet cutting slices polycarbonate using a high-pressure jet of water that contains abrasive powder in suspension. The waterjet stream, accelerated by the high-pressure pump, depends primarily on the abrasive particles to erode the polycarbonate and create the desired cuts. Abrasive waterjet cutting offers several advantages, including the ability to cut through polycarbonate sheets up to 12 inches thick.

- CNC Routing: Computer numerical control (CNC) routing uses automated cutting machines with rotating cutting tools to precisely cut and shape polycarbonate sheets. It is suitable for intricate designs, straight cuts, and curved edges.

- Saw Cutting: A fine-toothed saw or a circular saw can be used to cut polycarbonate sheets. It is a manual process that accommodates straight cuts and simple shapes.

Why Choose Xometry for Polycarbonate Laser Cutting Services?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get started with our easy-to-use platform and let our experts take care of managing the project from locating the right manufacturing partner to delivery logistics.

Vetted Network

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.