Direct Metal Laser Sintering (DMLS) 3D Printing Service

Upload your CAD files to get an instant quote on metal prototypes and production parts. Free shipping on all US orders.

High-Quality Metal Parts Without Tooling

Direct metal laser sintering (DMLS) is a metal 3D printing technology used to build metal parts with exceptional mechanical properties and precision. Our Manufacturing Supplier Network gives you massive on-demand production capacity with a wide range of DMLS machines and high-performance materials.

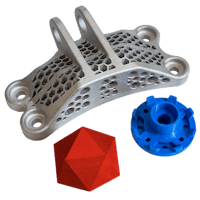

Designers often chose DMLS for its ability to produce all-in-one metal assemblies and highly precise metal parts with complex features like internal supports and lattices. DMLS does not have upfront setup or tooling costs, making it an affordable option for fully dense metal parts with the design freedom of additive manufacturing. With DMLS’s affordability, speed, and superior design freedoms, companies and creators can build metal designs they never thought possible and produce accurate metal components.

Xometry Direct Metal Laser Sintering 3D Printing Service Capabilities

| Feature | Description |

|---|---|

Feature Build Size | Description 10" x 10" x 10" (250 x 250 x 250 mm) |

Feature General Tolerances | Description +/- 0.005” for the first inch is typical, plus +/- 0.002” for every inch thereafter |

Feature Layer Height | Description .0012” - .0016" depending on material |

Feature Surface Roughness | Description 150-400 µin Ra, depending on build orientation and material used for the build |

Feature Infill | Description 100% |

This table depicts the general tolerances for Direct Metal Laser Sintering (DMLS). Stresses during the build and other geometry considerations may cause deviation in tolerances and flatness. Part designs with thicker geometries, flat or broad parts, and parts with uneven wall thicknesses may be prone to significant deviations or warp. Improved tolerances may be possible with a manual quote review, after successful completion of a prototype build, and must be approved on a case-by-case basis. General tolerances apply before secondary finishing or post-processing unless otherwise specified. Please check out Xometry's Manufacturing Standards for more information on tolerances per process.

Need to Compare Printing Processes?

Our quick reference guides let you quickly compare different 3D printing processes!

How a Direct Metal Laser Sintering Machine Works

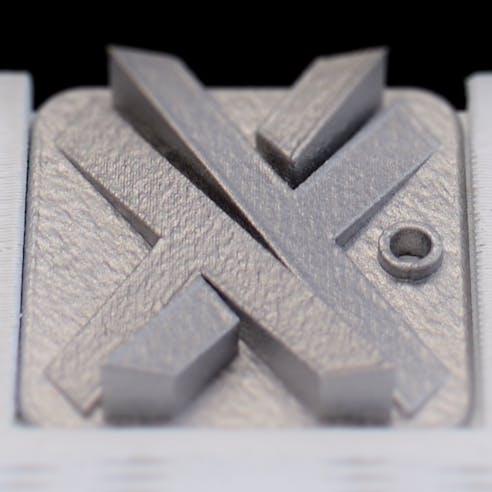

Direct metal laser sintering (DMLS) is an additive metal printing technology that builds metal parts from a CAD file by selectively fusing stainless steel or aluminum powder into thin layers.

Direct metal laser sintering’s layer-by-layer printing allows multiple parts to be combined during the printing process. With traditional manufacturing processes, metal parts are machined or metal casted into several parts and assembled. Printing an all-in-one assembly strengthens the finished part while reducing the weight and cost of production significantly. DMLS techniques can also create parts at a high density. This is ideal for parts under high pressure such as in oil and gas industries.

Direct Metal 3D Printing Materials

| Material Name | Description | Data Sheets |

|---|---|---|

Material Name 3D Printed Aluminum AlSi10Mg | Description Lightweight aluminum alloy. A great alternative to machining complex geometries. | Data Sheets |

Material Name 3D Printed Stainless Steel 17-4 | Description Fully-Dense 17-4 PH stainless steel metal, hardness 40 HRC, heat treatable. | Data Sheets |

Material Name 3D Printed Stainless Steel 316/L | Description Fully-dense 316L stainless steel metal, superb corrosion resistance, meets requirements of ASTM F138. | Data Sheets |

Available Finishes

Standard: In addition to the removal of support structures, the part surface is media blasted to provide a uniform finish.

Custom: Additional DMLS post-processing, such as CNC Machining of features and polishing, are evaluated on a case-by-case basis and can be requested in the quoting tool.

Best Applications for DMLS

Rapid Tooling

Because DMLS parts are strong yet lightweight, they are widely used for rapid tooling, fixtures, and jigs.

Rapid Prototyping

DMLS metal laser printing is typically affordable and fast, and therefore is often used to make proof-of-concept models and fully functional late-stage prototypes.

Production

Cast-quality finish (fully dense) and durable materials make DMLS printing a favorite technology for end-use products.

Ready to get started on your 3D printing quote?

Free shipping available for domestic 3D printing orders ; learn more!

Why Choose Xometry for DMLS 3D Printing?

Endless Options

Choose from thousands of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Vetted Network

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.