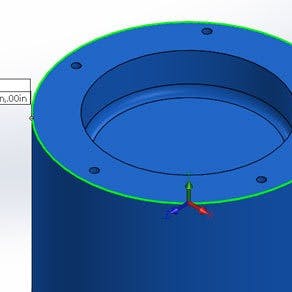

Bronze CNC Machining

Get instant quotes on custom bronze CNC machined parts with our Online CNC Machining Service. Make quick turn prototypes and production parts in days with free standard shipping on all US orders. ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified. ITAR registered.

Bronze CNC Machining

Bronze is made by mixing copper with up to approximately 35% tin and up to 8% lead. The inclusion of lead alloy, which is a soft metal, is what makes it so machinable. Bronze is great for applications such as bearings as well as marine applications on pumps and fittings where corrosion resistance against seawater is required. This material’s mechanical properties don’t quite measure up to many other machinable metals, so it is best used on low-stress components made with CNC machining.

Bronze, brass, and other copper alloys have a range of important electrical, mechanical, and corrosion-resistant properties. Specifically, bronze has excellent machinability, with an index of 100%. It also has low friction properties that make it ideal for parts that undergo continuous frictional contact.

Copper 932

Copper 932 is also known as bearing bronze. This alloy has excellent anti-friction properties, making it ideal for bearings, bushings, wear strips, and other light-duty applications.

| Tensile Strength, Yield (MPa) | Fatigue Strength (MPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm^3) |

|---|---|---|---|---|

Tensile Strength, Yield (MPa) 125 | Fatigue Strength (MPa) 110 | Elongation at Break (%) 20 | Hardness (Brinell) 65 | Density (g/cm^3) 8.93 |

Finishes and Post-Processing Options

Because quality bronze forms only a surface layer of oxidation, it does not corrode the way many other metals do. As such, it does not always have to be coated. Xometry offers a range of surface finishes that work well for bronze. These can include the standard as-milled surface, bead blasting, or chemical coatings to prevent oxidation. To learn more about what surface finish is best for your application, contact us here.

Cost-saving Design Tips

Bronze is a costly material and therefore its use must be optimized as much as possible.

Design for manufacturing: Following design for manufacturing principles is one of the easiest ways to reduce costs in the machining process. Bronze is more forgiving of complex features due to its machinability, but there is a limit and this needs to be understood before manufacturing begins. A Xometry expert can provide insight into what can be achieved with machining bronze.

Tolerancing: Bronze is easy to machine. Do not negate the production savings by over-tolerancing the part. This adds significant extra cost to the machining.