Acrylic CNC Services

Get instant quotes on machined acrylic parts with our Online CNC Machining Service. Make quick-turn prototypes and production parts in days with free standard shipping on all US orders. ISO 9001:2015, ISO 13485, and AS9100D certified. ITAR registered.

About Acrylic CNC Machining

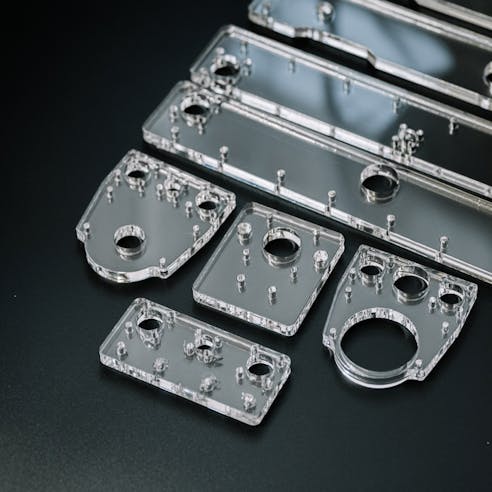

Acrylic is a thermoplastic known for its optical clarity, strength, and UV stability, making it a popular substitute for glass in many applications. It is lightweight, impact-resistant, and unlike other clear plastics, it does not discolor with prolonged exposure to sunlight. Although it offers excellent strength and stiffness, acrylic is not suitable for high-temperature environments, especially when compared to glass. Due to these properties, machined acrylic is widely used in industries such as automotive and test and measurement.

| Applications | Advantages | Disadvantages | Lead Time | Price | Tolerances |

|---|---|---|---|---|---|

Applications Instrument dials and vehicle lamp covers, light diffusers, transparent enclosures. Can be used as a low-cost and lightweight alternative to glass. | Advantages High impact resistance, optically clear, high UV resistance | Disadvantages Poor scratch and heat resistance, sensitive to certain chemicals (e.g., acetone, alcohol) | Lead Time Starting at 3 days | Price Low ($) | Tolerances Standard ±0.010"; ±0.002" are achievable; sub-±0.002" are available after manual review |

Acrylic

Acrylic is a tough material that has numerous benefits over glass. For one, acrylic can be easily machined whereas glass cannot. This gives you the option of CNC machining in acrylic when the task requires both complex geometry and high levels of optical clarity in the final part. Acrylic’s clarity makes it ideal for inspection windows, chemical testing hardware, and instrumentation covers.

| Tensile Strength, Yield (MPa) | Elongation at Break (%) | Hardness (Shore D) | Heat Deflection Temperature (°C) at 0.45MPa | Melting Point (°C) |

|---|---|---|---|---|

Tensile Strength, Yield (MPa) 65-75 | Elongation at Break (%) ~2-10 | Hardness (Shore D) ~80-90 | Heat Deflection Temperature (°C) at 0.45MPa 105-110 | Melting Point (°C) 85-110 |

Note: For reference only. Values can vary slightly depending on the grade and manufacturing process. For critical applications, refer to specific material data sheets (e.g., from manufacturers like Plexiglas®, Acrylite®, or Lucite®)

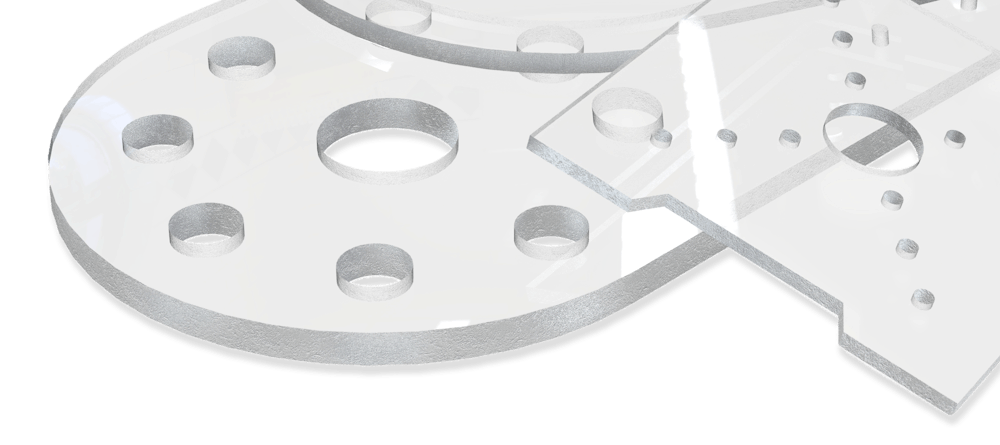

Finishes

Surface finishes are rarely applied to CNC machined acrylic because most would impede the material’s inherent optical properties. In cases where a finish is needed, opt for one that enhances these properties.

Standard (As-Machined): Visible tool marks on any cut face will show as swirls.

Bead Blast: Makes the acrylic a matte frosted appearance and mitigates visible tool marks.

Custom Polishing: Acrylic can be polished for additional clarity through chemical processes or manual progressive wet sanding at additional costs. This can be requested by selecting "Other" on the Xometry Instant Quoting Engine®.

Cost-saving Design Tips

Acrylic is a readily available material, but design within the limits of the material, as described below.

Design to standard sizes: Acrylic is typically supplied in sheets of varying thicknesses and extruded forms such as tubes and solid bars. Designing parts to fit within the dimensions of off-the-shelf sheet and bar stock will keep costs to a minimum. If the required part is too large, consider breaking it into multiple components that can then be glued or fastened together after machining.

Tolerancing: Achieving extra-tight tolerances with plastics like acrylic can be challenging. We recommend only calling out tolerances tighter than +/- 0.005" for critical features to reduce the increased scrap, cost, and lead times associated with tight tolerances.

Find more design tips in our CNC Machining Design Guide.