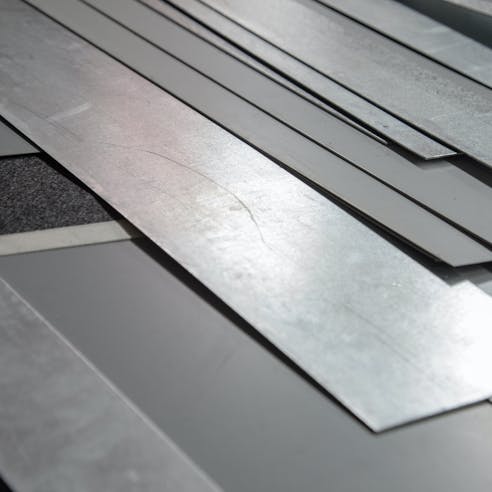

Steel Sheet Metal Fabrication Services

Upload your CAD files to get an instant online steel fabrication quote on custom formed steel sheet metal prototypes and production parts. Lead times as fast as days and free standard shipping on all US orders.

About Steel for Sheet Metal Fabrication

Steel is one of the most widely used manufacturing materials and offers a great balance between cost and functionality since it can easily be bent and welded. Steel typically contains about 1% carbon plus smaller amounts of other elements to improve its mechanical properties. Steel also responds well to heat treatment—a fact that can further improve its mechanical properties.

Steel is found in almost every industry from consumer products to heavy manufacturing. It is a low-cost material with good mechanical properties, excellent formability, and is also compatible with a wide range of surface finishes that can improve its corrosion resistance or enhance its aesthetics.

Steel 1018 (Mild Steel)

Generally referred to as mild steel, 1018 is highly formable, making it the ideal steel grade for steel fabrication parts. It has poor corrosion resistance so it needs some form of additional surface protection if it will be exposed to the elements or corrosive environments.

| Tensile Strength, Yield (MPa) | Shear Modulus (GPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm^3) |

|---|---|---|---|---|

Tensile Strength, Yield (MPa) 370 | Shear Modulus (GPa) 78 | Elongation at Break (%) 15 | Hardness (Brinell) 126 | Density (g/cm^3) 7.87 |

Finishes

Xometry offers a wide range of surface finishes that can be used for steel sheet fabrication applications.

Nickel plating: Carbon steels can be uniformly nickel-plated to improve their corrosion and wear resistance. This process deposits a 0.1 mm layer of nickel on the surface of the part.

Electroplating or Hot-dip Zinc Plating: Zinc plating is a popular surface finish for carbon steel components as it creates a robust layer of corrosion protection.

Powder coating: Powder coating creates a tough surface finish and is available in a wide variety of colors. Sheet steel parts tend to rust easily so powder coating can dramatically increase their usable lifespans.

Cost-saving Design Tips

Steel for sheet metal fabrication is a low-cost material but care must still be taken to manage expenditures.

DFM: The first opportunity to save costs on steel sheet metal parts is by following sheet metal DFM (design-for-manufacturing) principles. The design process itself should take into account the complexities of the manufacturing processes. An example is to include bend-relief cutouts that eliminate tears or cracks that might otherwise form at sharp bends. Review the Xometry Sheet Metal Design Guide to learn how to achieve the functionality you need using common sheet metal fabrication techniques.