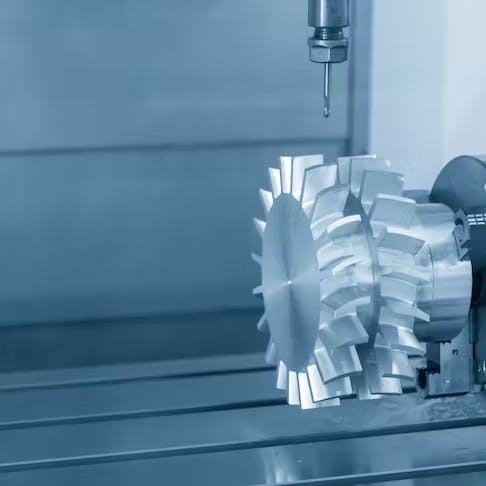

eBook: 3-Axis vs 5-Axis CNC Machining: Advantages and Disadvantages

Learn about these two CNC machining processes and how they can each be used.

Over time, CNC machines have gained popularity across most manufacturing sectors. These devices automate manufacturing processes such as: cutting, drilling, milling, and turning, and they do it all using computer numerical control (CNC) technology. CNC machines allow for the highly accurate and precise production of intricate designs and parts.

There are several kinds of CNC machines, but most fall under the 3-axis or 5-axis categories. These two differ in their axes of motion capabilities. This free eBook will discuss the advantages and disadvantages of 3-axis and 5-axis CNC machines.

A Look Inside

- What is CNC Machining?

- What is 3-Axis CNC?

- What Can a 3-Axis CNC Machine Do?

- 3-Axis CNC Machine Examples

- What are the Advantages and Disadvantages of 3-Axis CNC Machining?

- What is 5-Axis CNC Machining?

- What Can a 5-Axis CNC Machine Do?

- 5-Axis CNC Machine Examples

- What are the Advantages and Disadvantages of 5-Axis CNC Machining?

- What is the Difference Between 3-Axis and 5-Axis CNC Machining?

- How Much Does 5-Axis CNC Cost Compare to 3-Axis CNC?

- Frequently Asked Questions About 3-Axis and 5-Axis CNC Machining