Custom Metal 3D Printing Service

High-quality Industrial Metal 3D Printing | DMLS and Metal Binder Jetting Services | Free Shipping on All US Orders | No Minimums

What is Metal 3D Printing?

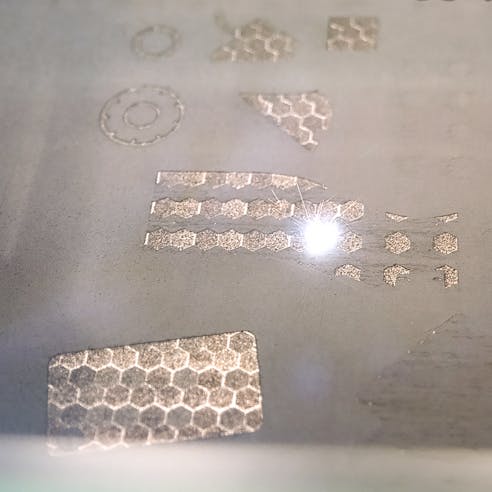

Metal 3D printing, an additive manufacturing process, produces parts by fusing metal particles layer by layer to form a metal part. It is often chosen as an alternative to CNC machining or metal casting because it can produce parts with the strength and durability of metal while also taking advantage of the design freedoms afforded by 3D printing. It can produce complex designs, including lattices and topology-generated structures, both of which are impossible to manufacture via traditional CNC machining.

Advantages of Metal 3D Printing

Metal 3D printing is advantageous because it can produce high-performance, complex metal parts suited to a range of end-use environments. Metal 3D-printed parts are isotropic, meaning they have uniform, multi-directional strength and the superior mechanical properties of metals like aluminum, stainless steel, titanium, and Inconel.

3D metal printing can also be used to consolidate assemblies into a single part, where they would otherwise require separately machined components. This can result in a stronger structure by reducing the points of failure introduced by threads and inserts.

With metal 3D printing, parts are produced directly from CAD data without the need for tooling, molds, or complex fixturing. This makes it especially cost-effective for highly complex geometries, lightweight designs, and low-volume production. Unlike machining, where increased complexity drives up programming time, tooling, and material waste, metal 3D printing enables features such as internal channels, lattice structures, and topology-optimized forms with minimal impact on cost. In many cases, complex metal 3D-printed parts can be produced in days rather than weeks.

Metal 3D Printing

Direct Metal Laser Sintering (DMLS) 3D Printing Service

Metal Binder Jetting 3D Printing Service

Choosing Between DMLS or Binder Jet Metal

Xometry's 3D metal printing services include direct metal laser sintering (DMLS) and metal binder jetting as options. These processes are suitable for creating metal prototypes, tooling, and production parts on demand. However, each metal 3D printing process uses different metals and fusing methods, resulting in parts with different mechanical properties, prices, and lead times.

Overview of Direct Metal Laser Sintering

DMLS, also known as selective laser melting (SLM), uses a laser to selectively fuse sections of fine metallic powder from the ground up. DMLS is advantageous because it can produce fully dense parts for fluid transfer applications. DMLS can produce parts from popular alloys such as aluminum AlSi10Mg and stainless steel, as well as more exotic metals like maraging steel and Inconel. It is more expensive than metal binder jetting but has superior mechanical properties and accuracy for high-precision applications. Learn more about DMLS materials, post-processing, tolerances, and applications →

Overview of Binder Jet 3D Printing

Metal binder jet is a multi-step process that first selectively deposits a binding agent onto a metal powder bed, layer by layer, to hold the metal powder in a 3-dimensional shape. This resulting shape is left to cure, then placed in a furnace to sinter or be infiltrated with bronze. Binder jet parts with overhanging features are supported by loose powder on all sides, eliminating the need for support structures and simplifying post-processing.

Binder jetting is a popular metal 3D printing choice because parts are cheap and fast, enabling higher-volume, cost-effective production. Binder-jetted metal parts are excellent for functional prototypes or end-use parts with a density of ~95% or higher. Metal binder jetting is also widely used by artists and hobbyists because it can create complex features at a fraction of the cost of DMLS or machining. Unlike DMLS, binder jet parts are prone to shrinkage, so engineers should design parts with design-for-manufacturing principles in mind. This could include scaling their CAD model size by 1-2% and enlarging holes. Learn more about binder jetting materials, post-processing, tolerances, and applications →

Direct Metal Laser Sintering Materials

- Aluminum AlSi10Mg

- Stainless Steel 17-4

- Stainless Steel 316/L

Metal Binder Jetting Materials

- Single alloy 316L SS

- Other materials subject to market availability

Applications of Metal 3D Printing in Various Industries

Metal 3D printing can be used for rapid industrial tooling, where the metal 3D print can be used for parts with complex curvatures and small, thin-walled parts like conformal jigs and fixtures, stamps, dies, and cutting inserts.

For other industries like consumer products, robotics, aerospace, and defense, metal 3D printing can be used for integrated fastening features, end-effectors, and metal lattice structures. Since metal 3D printed parts have excellent durability and strength, they can be used in fully functional late-stage prototypes or end-use parts for any of the above applications.

Read about how this global distributor uses DMLS for custom shading systems, including high-strength coupling brackets and zipper assemblies.

Ready to get started on your custom metal 3D printing quote?

Free shipping available for domestic 3D printing orders ; learn more!

Why Choose Xometry for 3D Metal Printing Service?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Vetted Network

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

Get the DMLS Design Guide