Xometry's Inspection Services

Xometry offers inspection as part of the Instant Quoting Engine. These can include formal inspection reports, CMM measurements of GD&T dimensions, source inspection, and more. Each inspection offering and its definition and which processes it applies to are detailed below.

Xometry's Inspection Selections

Standard Inspection

- QC will verify that the part material, features, and finish are in accordance with the part requirements specified in the quote, CAD file, and/or print. If no dimensional print is provided with a part, QC measures to Xometry's Manufacturing Standards on dimensions they deem critical, such as overall size, holes, and depths. If a dimensional print is provided, QC will verify up to 20 dimensions they deem critical. Documentation will not be shipped with your parts.

Formal Inspection with Dimensional Report

- QC will perform an inspection using calibrated tools where 100% of all dimensions, attributes, dimensional locations, and print notes will be documented per our Statistical Sampling Plan based on ASQC Z1.4 2008 Level II with Zero rejects. A dimensional inspection report with a correlated ballooned print will be shipped with your part(s). A customer-supplied dimensional print is required for this inspection. The number of inspection points is subject to the applicable 100 maximum. Greater quantities require a Custom Inspection and additional charges.

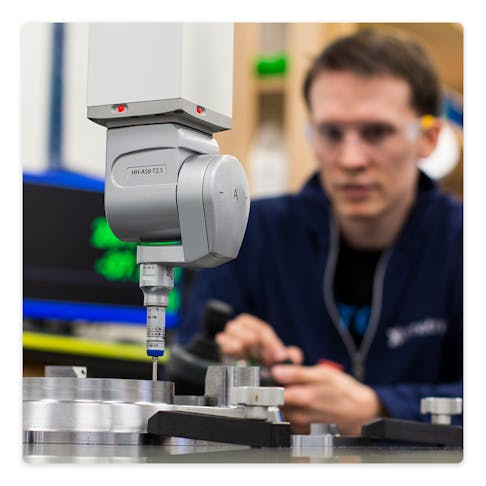

CMM Inspection with Dimensional Report

- QC will perform an inspection using a Coordinate Measurement Machine (CMM) where 100% of all dimensions, attributes, dimensional locations, and print notes will be documented per our Statistical Sampling Plan based on ASQC Z1.4 2008 Level II with Zero rejects. A dimensional report with a correlated ballooned print will be shipped with your part(s). A customer-supplied dimensional print is required for this inspection. The number of inspection points is subject to the applicable 100 maximum. Greater quantities require a Custom Inspection and additional charges.

First Article Inspection Report (FAIR AS9102)

- QC will perform a First Article Inspection per the requirements specified in SAE Aerospace Standard (AS 9102) documentation (or equivalent). The purpose of the First Article Inspection is to provide objective evidence that all engineering design and specification requirements are properly understood, accounted for, verified, and documented.

QC will maintain a quality record for customer review of accountability and planning, for performing periodic surveillance and audits to verify conformance, for evaluating root cause and corrective action for any non-conformances, and for problem investigations. A dimensional report with a correlated ballooned print will be shipped with your part(s). Random sampling is based on ANSI/ASQ Z1.4 Level II to an Acceptance Quality Level (AQL) of 2.5%. A customer-specified dimensional print is required for a First Article Inspection. We will build the full lot and do the FAI form at the final QC treating this lot like the first Article. If you want a 1 part and stop for approval, please select custom inspection. The number of inspection points is subject to the applicable 100 maximum. Greater quantities require a Custom Inspection and additional charges.

Source Inspection

- A Source Inspection audit is an inspection of purchased products and process records at the supplier's premises to verify compliance with requirements before shipment to the customer. A Source Inspection can include but is not limited to requirements review, specification compliance, and a quality review of the manufacturer. A source inspection will be scheduled based on the order lead time and when parts are ready to ship. The order will ship after the source inspection is complete. A customer-supplied dimensional print is required for this inspection.

Custom Inspection

- Choose this option if your part requires other inspection requirements such as, but not limited to, the following: Non-Destructive Testing, Serialization, Custom Sampling Plan, or if you would like to provide your own inspection datasheet. A customer-supplied dimensional print is required for this inspection.

Can Xometry Inspect Additive Manufactured (3D Printed) Parts?

Xometry also offers some of these inspection processes for additive manufacturing services! However, there are aspects to these inspections that differ slightly from the descriptions described above. Please visit our Additive Inspections Options article for detailed information on our available inspection options for 3D printed parts.

| Process | Standard Inspection | Formal w/ Dimensional Report | CMM w/ Dimensional Report | First Article Inspection Report | Source Inspection | Custom Inspection |

|---|---|---|---|---|---|---|

Process CNC Machining | Standard Inspection ✔️ | Formal w/ Dimensional Report ✔️ | CMM w/ Dimensional Report ✔️ | First Article Inspection Report ✔️ | Source Inspection ✔️ | Custom Inspection ✔️ |

Process Sheet Cutting | Standard Inspection ✔️ | Formal w/ Dimensional Report ✔️ | CMM w/ Dimensional Report ✔️ | First Article Inspection Report ✔️ | Source Inspection ✔️ | Custom Inspection ✔️ |

Process Sheet Metal | Standard Inspection ✔️ | Formal w/ Dimensional Report ✔️ | CMM w/ Dimensional Report ✔️ | First Article Inspection Report ✔️ | Source Inspection ✔️ | Custom Inspection ✔️ |

Process Injection Molding | Standard Inspection ✔️ | Formal w/ Dimensional Report -- | CMM w/ Dimensional Report -- | First Article Inspection Report ✔️ | Source Inspection ✔️ | Custom Inspection ✔️ |

Process Urethane Casting | Standard Inspection ✔️ | Formal w/ Dimensional Report -- | CMM w/ Dimensional Report -- | First Article Inspection Report ✔️ | Source Inspection ✔️ | Custom Inspection ✔️ |

Process Additive / 3D Printing* | Standard Inspection ✔️ | Formal w/ Dimensional Report ✔️ | CMM w/ Dimensional Report -- | First Article Inspection Report -- | Source Inspection -- | Custom Inspection ✔️ |

* All additive manufacturing processes except for PolyJet or Metal Binder Jetting. Learn more about our Inspection and Sampling Plans.

FAQ:

Does the Standard Inspection include a dimensional report?

No. A standard inspection is a simple dimensional check and no documentation will ship with your parts.

How can I receive a dimensional inspection report?

Upgrade to Formal Inspection with Dimensional Report, CMM Inspection with Dimensional Report, or First Article Inspection to receive a full dimensional inspection report that is correlated to your drawing.

Can you verify GD&T geometric tolerances like position, flatness, surface profile, parallelism, etc...?

Yes. If your part has GD&T requirements, it must be inspected using a Coordinate Measuring Machine. Please choose the CMM Inspection with Dimensional Report option. The exception to this is additive manufactured parts.

Do you offer First Article Inspections?

Yes. Either the First Article Inspection Report (FAIR AS9102) option or a Custom Inspection option would be required depending on the requirements. If you want one part and stop for approval, please select Custom Inspection.

What can I expect to see with a dimensional report?

A dimensional inspection report will include a correlated ballooned print. Please visit our Sample Inspection Documents page for documentation examples.

Where can I learn more about your inspection options?

You can learn all about our inspection options and the sampling plan that we follow here: Inspection and Sampling Plans