Insert Molding vs. Overmolding: What's the Difference?

There are various sub-processes within injection molding that add further capabilities to this already versatile technology. This article will explore insert molding vs overmolding and the advantages of each.

Injection molding is a broad term used to describe one of the most important processes in the manufacturing industry. It’s a process that requires a mold, typically made of metal with a cavity in the shape of the desired part. Molten plastic is injected into the mold and ejected. The process repeats to produce thousands of identical parts. It’s safe to assume that every large-volume plastic part on the market has come from an injection molding machine because the benefits of using injection molding for production are numerous. These benefits include low cost per part, short cycle times, extensive materials, and compatible, in-tolerance parts.

Various sub-processes add further capabilities to this already versatile technology. This article will specifically explore insert molding vs. overmolding and the advantages of each.

What is Insert Molding?

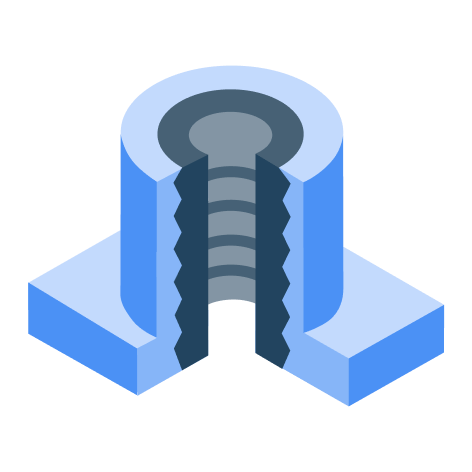

Insert molding is a subset of injection molding techniques similar to overmolding where metal components are placed into a mold cavity before the actual plastic injection. The insert is precisely positioned inside the mold either manually or by a robotic arm. The mold then closes, and plastic is molded over the insert, creating a single part.

One of the most common applications for insert molding is the creation of metal attachment features for fasteners. Fasteners enable assemblies to be securely assembled and disassembled without product damage. Heat-set threaded inserts are molded into plastic to reduce the risks of thread damage during installation.

Insert molding can also eliminate the need for fasteners by including the necessary metal parts in the mold, thus firmly securing the parts into a single bonded component.

Insert Molding Benefits

Insert molding is a versatile process that has numerous benefits, some of which are listed below.

- Reduced Assembly Cost - An injection molding machine can create thousands of parts per day. Such economies of scale can significantly reduce the cost of the individual parts. In a typical CNC machined, sheet metal, or additive manufactured part, any required assembly can be a major bottleneck. Insert molding can be used to eliminate assembly and thus maximize cost savings.

- Part Performance - In general, plastic parts are less robust than their metal counterparts. However, plastic offers other benefits such as reduced cost, superior design flexibility, and lighter weight. Combining both metal and plastic materials into one part can capitalize on the benefits of both. Metal inserts can be used where strength and stiffness are required and the remainder of the part can be made of plastic to reduce weight. Moreover, plastic parts do not fare well against wear and tear and metal inserts add an element of durability to parts to withstand any kind of cyclical loading.

FREE Injection Molding Design Guide

Disadvantages of Insert Molding

Despite the many benefits of insert molding, a few disadvantages need to be considered before choosing to use this sub-process.

- Multiple Manufacturing Technologies - Insert molding can involve a 2-step manufacturing process. If the inserts are a custom design and not off-the-shelf parts, they will need to be manufactured using a metal forming process like CNC machining. These metal forming techniques are often significantly more expensive per part than similar, fully injection-molded processes. In some cases, the metal parts can be manufactured via die casting or MIM (metal injection molding). This can reduce the overall cost of the metal inserts but cannot eliminate the insert molded unit's increased cost because parts with metal inserts will typically cost more than a part that is only plastic.

- Increased Part Complexity - If a custom-made metal insert is required, the designer must be aware of both technologies' design for manufacturability (DFM) principles and understand how best to integrate these technologies into a single practical part.

What is Overmolding?

Overmolding is essentially a type of insert molding. However, overmolding vs. insert molding is, as the name suggests, plastic is molded over another molded part. The first component is made inside an injection mold, and it is then placed into a second mold to add the over-molded material. This technique combines multiple plastics for either practical or aesthetic purposes. For example, one might use different durometer plastics to mold a softer plastic over a more rigid one to make a part easier to grip. Using multiple colored plastics in an overmolded part can also distinguish the product from other brands. Overmolding is regularly used on the handles of tools like screwdrivers, power drills, or toothbrushes.

Overmolding Benefits

Overmolding is a versatile process that has numerous benefits:

- Increased Material Flexibility - Overmolding allows designers to leverage the benefits of multiple types of materials to create complex parts with different properties, add visual complexity, or add haptics.

- No Adhesives Required - Overmolding allows different materials to be fused in the mold, thus eliminating the need for glues or other permanent bonding methods. This increases the part's overall durability and reduces assembly costs.

- Embedded Seals - Overmolding offers the option of molding soft seals into parts. An example would be an electronics enclosure that needs to be IP rated. Usually, the part will have a groove into which an o-ring can be installed later. However, it is far more cost-efficient and robust to permanently mold the seal as an integral component.

Disadvantages of Overmolding

Despite the many benefits of overmolding, a few disadvantages need to be considered before deciding to use this process.

- Multi-Step Process - Overmolded parts are made in a two-step process. This increases part cycle time and is thus more expensive than molding a single part with no overmolding. This also requires two tools, or a complex two-shot mold with increased upfront costs. However, when the alternative is to create two separate injection-molded parts and then assemble them after the fact, overmolding becomes a value-added solution.

- Debonding - Bonding two different materials together in an injection mold runs the risk of delamination. This typically happens if the temperatures are not in the optimal range for the specific material combination. In some cases, mechanical interlocks may be required when materials cannot be reliably bonded together using heat.

Conclusion: Choosing Between Insert Molding, Overmolding, or Injection Molding

Injection molding, which includes the sub-processes insert molding and overmolding, is a versatile and low-cost manufacturing production process that is used in the large majority of consumer products. Injection molding often results in the lowest cost per part when compared to other manufacturing techniques like CNC machining and even 3D printing.

Once injection molding is chosen for a specific application, the next step is often whether to use insert molding, overmolding or just stick with plain injection molding. When trying to weigh the advantages of the processes, it is important to accurately define the product application. Each of these processes has specific use cases that are suited to different product types. It can be difficult to gauge which process will best suit your particular product, so it’s good to get expert advice early on. Contact a Xometry representative to leverage decades of vast manufacturing expertise. We will help steer your design decisions in the right direction so that you can choose between insert molding vs. overmolding or just injection molding.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.