Bulk 3D Printing Service by Xometry

Get instant online quotes on bulk 3D printed parts in over 70 metal and plastic materials. Free shipping on all US orders. ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified.

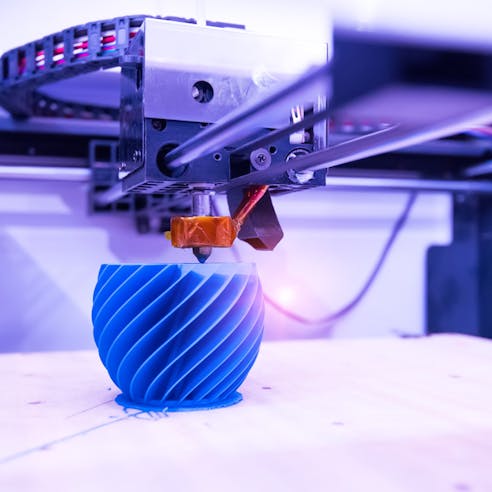

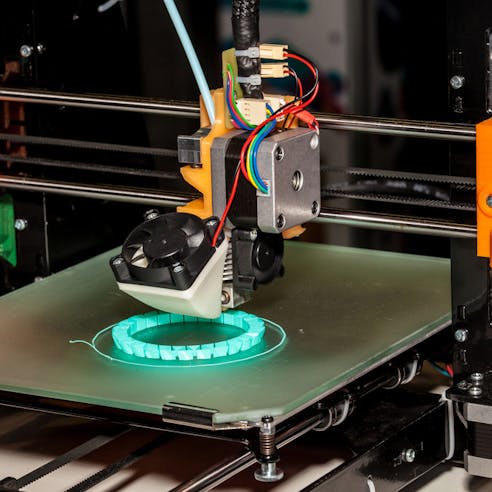

Bulk 3D printing or high-volume additive manufacturing is a way to print large quantities of parts or components in a single production run. The aim is to combine the benefits of large-scale manufacturing with those of additive manufacturing (which is typically a low-volume technique).

Since it is an additive process, there is minimal material waste. Digital precision eliminates the need for costly tooling and greatly reduces production time. 3D printing can be more economical, although this benefit is usually more prominent for small batches or prototypes. On-demand manufacturing is also an option — businesses can produce parts as needed rather than keeping inventory on the shelf. As a result, they can produce parts rapidly and minimize the time-to-market lag, giving them a competitive edge in the industry. Additionally, designers and engineers have more freedom to innovate because they can iterate and improve designs even after the production run has begun.

Bulk 3D Printing Process

Xometry’s bulk 3D printing service is a seamless process from project consultation to final production. We begin with a thorough project consultation. Our team of experts works closely with you to understand your specific requirements, including project scope, desired materials, and target quantities. After that, our engineering team focuses on design optimization. Leveraging our extensive expertise in additive manufacturing, we fine-tune the 3D models to ensure they are well-suited for bulk production. With the optimized designs in hand, we can then create prototypes. Once you approve the prototypes, we initiate the full-scale production process. Our advanced 3D printing facilities enable us to efficiently produce large quantities of parts in a cost-effective manner. Throughout the entire bulk 3D printing process, we implement rigorous quality control measures to guarantee high-quality parts.

Materials and Technologies Used in Bulk 3D Printing

Large-scale 3D printing harnesses the power of automation and state-of-the-art 3D printing facilities to achieve rapid production cycles. Optimized designs, batch processing, and meticulous nesting techniques optimize the use of the build volume, effectively reducing print times and bolstering overall efficiency.

At Xometry, we take pride in our comprehensive range of bulk 3D printing services based around cutting-edge materials and advanced industrial-grade 3D printers. Our commitment to delivering high-quality parts at scale is made possible through technologies such as multi-jet fusion, fused deposition modeling (FDM), selective laser sintering (SLS), and other additive techniques. We can accommodate a wide selection of advanced materials to cater to diverse industry requirements. These materials include engineering plastics (nylon, AB, PLA, PETG, and PC), high-performance plastics (PEI, PEEK, and PPSF), and metal alloys (aluminum, stainless steel, and titanium).

Benefits of Bulk 3D Printing

Bulk 3D printing offers a multitude of advantages:

- Time-Savings

- Cost Effective

- Material Efficiency

- Design Flexibility

- Custom Parts

- Low Tooling Costs

- On-Demand Production

- Fast Turnaround

- High-Quality Products

Time-Savings

Bulk 3D printing is often much quicker than traditional manufacturing methods in terms of the full production cycle. The streamlined digital production process eliminates the need for time-consuming tooling.

Cost Effective

3D printing is a cost-effective production method. With low tooling costs and minimal material waste, you can save significantly on the input side and gain a better return on investment.

Material Efficiency

Additive manufacturing is inherently material-efficient. It builds parts layer-by-layer, adding material only where the structure needs it. You don’t end up with large amounts of wasted scrap and swarf like that produced by subtractive manufacturing methods.

Design Flexibility

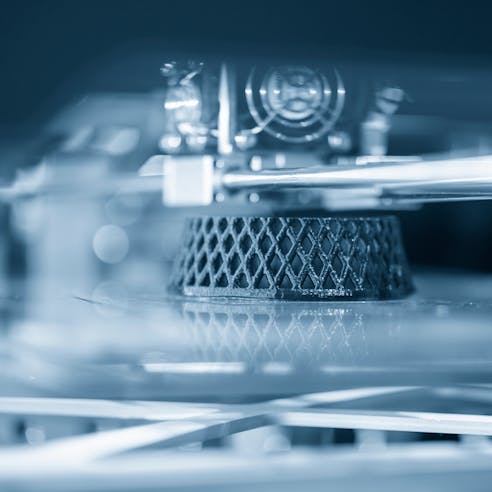

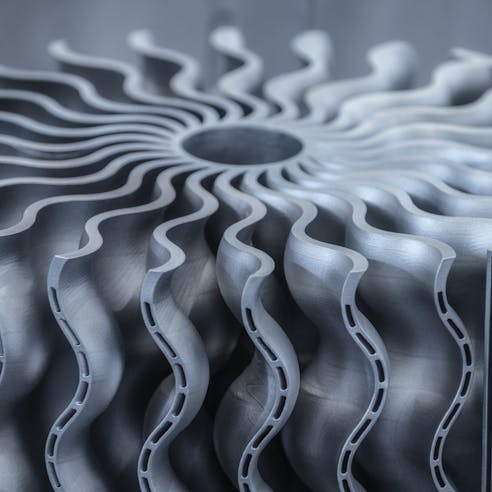

Large-scale 3D printing retains the inherent flexibility of additive manufacturing. It allows tailored designs and functional specifications to be incorporated within a single production run. Your engineers can incorporate complex geometries and intricate structures that may be impractical, costly, or physically impossible with traditional techniques.

Custom Parts

Bulk 3D printing enables the production of custom parts tailored to specific applications. Since digital designs are simple to modify and need no tooling changes, you can address individual customer needs and offer personalized solutions.

Low Tooling Costs

Unlike traditional manufacturing, which often requires expensive molds, dies, and other tooling, 3D printing operations are cheap and simple to initiate. This cost advantage is particularly beneficial for producing small batches or prototypes.

On-Demand Production

Parts can be 3D printed on an on-demand basis, so there’s no need to store an extensive standing inventory. This just-in-time approach minimizes inventory costs and the risk of overstocking.

Fast Turnaround

The rapid production capabilities of bulk 3D printing allow for quick turnaround times from design to finished products. This agility is especially valuable if you need to meet tight project deadlines and address urgent market demands.

High-Quality Products

Advanced 3D printing technologies and industrial-grade printers create consistent and high-quality results. The stringent quality control measures employed by reputable service providers such as Xometry guarantee that the final parts will meet or exceed industry standards.

Ready to start making custom bulk 3D printed parts?

Free shipping on all US 3D printing orders

Drawbacks of Bulk 3D Printing

The key drawbacks of bulk 3D printing include:

- Limited Materials

- Post-Processing Requirements

- High Initial Costs

- Material Quality Consistency

- Size Limitations

- Lack of Standards

Limited Materials

Compared to traditional manufacturing processes, bulk 3D printing is limited to a smaller palette of materials. While the selection of 3D printable materials is continuously expanding, not all specialized materials will work using current printing technologies.

Post-Processing Requirements

Despite the precision and accuracy of 3D printing, many printed parts still require post-processing to achieve the ideal surface finish, texture, or mechanical properties. Depending on the complexity of the parts and the intended application, you may need to add finishing steps such as: support removal, curing, sanding, sintering, smoothing, polishing, painting, CNC milling, or heat treatment.

High Initial Costs

The earliest stage of creating an additive manufacturing setup — buying the printer and associated equipment — is more expensive than many traditional manufacturing methods. Industrial-grade 3D printers and advanced equipment can be cost-prohibitive for some businesses, especially those starting with limited resources.

Material Quality Consistency

The quality and properties of 3D printing materials can vary based on batch-to-batch variations or the quality of the raw materials. This inconsistency might be a concern for applications that require strict material performance standards.

Size Limitations

Most 3D printing technologies have size limitations based on the printer’s physical dimensions. If you need to create large components, that fact alone may eliminate bulk 3D printing as an option.

Lack of Standards

The 3D printing industry lacks the same level of standardization seen in traditional manufacturing when it comes to technologies and materials. This poses a challenge for manufacturers who depend on safety or quality certifications. They may simply not be able to guarantee quality for their customers.

Applications of Bulk 3D Printing

Bulk 3D printing finds extensive use across various industries, including:

- End-Use Parts

- Rapid Prototyping

- Tooling

- Jigs and Figures

- Custom Parts

- Complex Geometries

End-Use Parts

Bulk 3D printing can turn out fully functional end-use parts. This is particularly advantageous for industries that focus on customized or low-volume production, such as aerospace, automotive, medical devices, and consumer goods.

Rapid Prototyping

3D printing has been a game-changer in rapid prototyping. Businesses can quickly iterate and refine product designs, reducing the development cycle and speeding the time-to-market. Rapid prototyping with 3D printing allows for efficient testing and validation of design concepts before moving to full-scale production.

Tooling

3D printing is increasingly used to create custom tooling for various manufacturing processes. Tools, molds, and dies can be produced quickly and inexpensively, improving production efficiency and enabling even more types of small-batch or custom manufacturing.

Jigs and Figures

Bulk 3D printing is well-suited for the production of jigs, fixtures, and other manufacturing aids. These tools are used to ensure precision during assembly, machining, and inspection processes.

Custom Parts

3D printing is ideal for customized production. From personalized medical implants to unique consumer products, bulk 3D printing enables businesses to cater to individual customer needs and preferences.

Complex Geometries

3D printing is well-suited for creating parts with complex geometries that may be difficult or impossible to achieve through traditional manufacturing.

Bulk 3D Printing Industries

Our bulk 3D printing service can cater to nearly any industry. Here are a few of the most common:

- Automotive

- Aerospace

- Consumer Goods

- Healthcare

- Industrial

- Architectural

- Electronics

- Education

Automotive

In the automotive sector, bulk 3D printing is utilized for rapid prototyping, end-use parts, and custom components. It enables manufacturers to optimize designs, reduce production costs, and get their vehicles or parts to market quickly.

Aerospace

The aerospace industry embraces bulk 3D printing for lightweight and high-performance parts. From complex engine components to cabin elements, 3D printing provides the precision and design flexibility that aircraft manufacturing and maintenance needs.

Consumer Goods

Bulk 3D printing is employed to create customized and unique consumer products. From personalized phone cases to fashion accessories, 3D printing allows businesses to offer tailor-made designs and respond quickly to changing consumer demands.

Healthcare

In the healthcare sector, bulk 3D printing plays a pivotal role in producing medical devices, prosthetics, and surgical instruments. This technology enables precise and patient-specific solutions that enhance treatment outcomes and patient care.

Industrial

Industrial machinery, manufacturing equipment, and robotics can all benefit from parts made in bulk 3D printing operations. Create custom tooling, jigs, and fixtures this way and you’ll streamline production processes and increase operational efficiency.

Architectural

The architecture industry employs bulk 3D printing to create complex models, prototypes, and large-scale architectural elements. 3D printing allows architects to visualize and test designs effectively, leading to more efficient construction and design decision-making.

Electronics

Electronics producers can quickly print custom enclosures, prototypes, and small batches of specialized components. This ability to rapidly iterate designs and create intricate electronic housings enhances product development and innovation.

Education

Educational institutions utilize bulk 3D printing both to demonstrate the technology and create teaching aids. Students can practice designing, iterate on their ideas, and learn from tangible experiences in ways that won’t cost the school as much as ordinary subtractive manufacturing.

Alternatives to Bulk 3D Printing

When it comes to bulk production, several alternative manufacturing methods exist alongside bulk 3D printing. Here are three prominent alternatives to consider:

- Injection Molding

- CNC Machining

- Sheet Metal Fabrication

- Die Casting

- Injection Molding: Injection molding is an efficient mass-production technique for creating plastic or metal parts in large quantities. The molten material is injected into a mold cavity and takes the shape of the mold as it solidifies. Injection molding is best suited for very large quantities of identical parts with tight tolerances and complex geometries. It is commonly used in automotive parts, electronics, and consumer goods. While tooling costs can be significant, the per-unit cost decreases substantially with increasing production volumes, making it a cost-effective option for large-scale production.

- CNC Machining: CNC machining is a subtractive manufacturing process that uses computer-controlled machines to cut and shape material stock into finished parts. It is ideal for precise and intricate components — especially those made of metals, plastics, and composites. CNC machining offers excellent material versatility and is suitable for small to medium production volumes. Although it may not be as cost-effective as injection molding for extremely high volumes, CNC machining is better for producing functional prototypes, custom parts, and components with demanding tolerances in industries like aerospace, medical, and automotive.

- Sheet Metal Fabrication: Sheet metal fabrication is employed to shape metal sheets into components such as enclosures, brackets, and panels. The sheets get cut, bent, and assembled as needed. Sheet metal fabrication is well-suited for high-volume production, especially for parts that require strength, durability, and precise dimensions. It is commonly used in the automotive, electronics, and construction industries. The method's efficiency lies in its ability to create consistent and cost-effective parts from inexpensive sheet metal stock.

- Die Casting: Die casting is designed specifically to make metal parts with excellent surface finishes and dimensional accuracy. Molten metal is forced into a mold under high pressure and then cools to solidify the part. Die casting is widely used in the automotive, aerospace, and electronics industries for components like engine housings, gearbox casings, and electronic enclosures.

Why Choose Xometry for Bulk 3D Printing?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

We are ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified.

Get Started on Your Bulk 3D Printing Quote

Free shipping on all US 3D printing orders