Resin 3D Printing Services by Xometry

Instant quotes for high-quality, high-resolution 3D prints | Get instant pricing and lead times with parts delivered in days

Resin 3D Printing With Xometry

Resin-based 3D printing is great for applications that demand high detail, smooth surface finishes, and precision. These processes produce finely detailed features and maintain tight tolerances, making them ideal for industries like product design, healthcare, and engineering, where aesthetics and accuracy are crucial. Unlike other additive manufacturing techniques, resin 3D printing processes deliver parts with negligible layer lines, making them preferable when minimal post-processing is desired or where visual presentation is key.

Xometry offers a wide array of resins, from general-purpose to clear to highly engineered composite resins. We have multiple resin-based 3D printing processes to precisely meet your needs.

What is Resin 3D Printing?

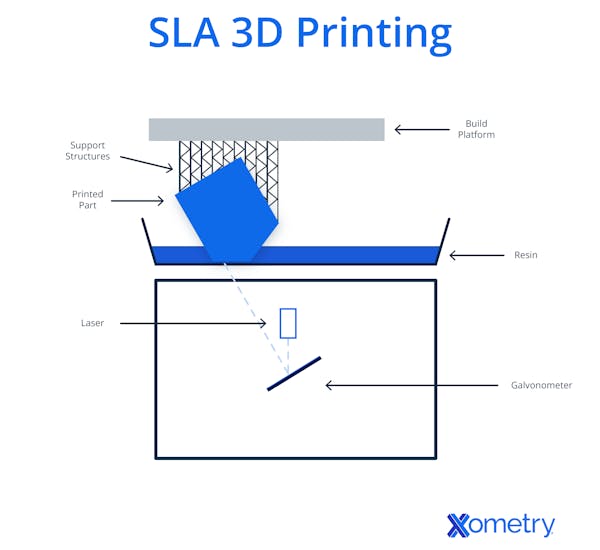

Resin 3D printing is a broad category of additive manufacturing processes that create objects by curing liquid photopolymer resins with light. Rather than referring to a single method, it encompasses several related technologies, such as SLA, DLP, and mSLA, all of which work on the same core principle: building parts layer by layer through controlled exposure of resin to a light source.

During printing, targeted regions of the resin are exposed to light, initiating a photopolymerization reaction that solidifies the material. Each cured layer bonds to the previous one, gradually forming the complete 3D object. Because these processes can achieve layer resolutions as fine as 25 microns and capture sub-millimeter features with smooth surfaces, resin 3D printing is especially well-suited to applications requiring high dimensional accuracy, intricate detail, and excellent surface quality.

Types of Resin 3D Printing Technologies

Xometry offers instant quoting for multiple resin-based 3D printing processes. The sections below outline each technology we offer and what distinguishes them:

Stereolithography (SLA)

Stereolithography (SLA) is the earliest and most established resin 3D printing technology, distinguished by its use of a precisely directed laser to trace and cure each layer of a part. SLA’s laser-driven approach enables exceptionally consistent accuracy across very large build areas, making it well-suited for producing oversized parts without sacrificing detail. Our industrial SLA platforms support build volumes up to 29” × 25” × 21”, allowing us to manufacture everything from small, intricate pieces to large-format components.

PolyJet

PolyJet 3D Printing is a resin-based process that sets itself apart by jetting and curing tiny droplets of liquid photopolymer directly onto the build platform, similar to how an inkjet printer deposits ink. This approach allows for simultaneous printing of multiple materials and full-color elements, enabling parts with varying flexibility, transparency, and realistic surface textures within a single build. PolyJet is particularly well-suited for creating highly detailed concept models and prototypes that closely mimic the appearance and tactile qualities of the final product. However, its materials are less durable and unsuitable for demanding end-use applications, making PolyJet primarily a solution for visual, ergonomic, and design-validation models rather than functional parts.

Carbon DLS™

Carbon DLS™ (Digital Light Synthesis) is a DLP-based resin 3D printing technology that operates through continuous light exposure combined with an oxygen-permeable interface, enabling parts to be produced in a layerless, seamless manner. Unlike conventional layer-by-layer DLP printing, this approach delivers isotropic mechanical properties, superior surface quality, and parts that can withstand functional use, making it ideal for end-use components, functional prototypes, and small production runs. Carbon DLS™ also supports a range of engineering-grade resins, including rigid plastics and flexible elastomers, enabling designers and engineers to produce production-ready parts directly from the printer.

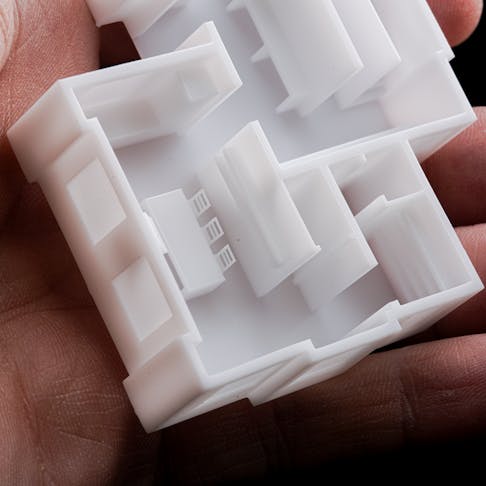

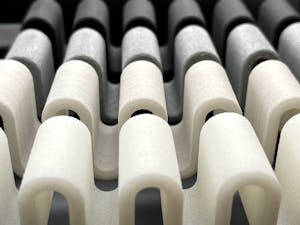

Parts made from a variety of Formlabs SLA resins.

Resin 3D Printing Materials

Xometry offers a diverse range of photopolymer resins, enabling the production of parts with tailored properties. However, this variety necessitates careful material selection based on specific project requirements. To simplify things, we've categorized our resins by their primary use and attributes.

General Purpose Resins

General purpose resins are designed to provide a balanced combination of strength, stiffness, and surface finish, making them ideal for a wide range of applications. They are commonly used for initial prototypes, form-and-fit validation, and less demanding functional testing, where a part needs to represent the final product’s shape and dimensions without necessarily matching its full mechanical performance. These resins offer reliable, cost-effective performance across multiple resin-based printing technologies, making them a versatile choice for early-stage design and development.

Popular general purpose resins include Accura SL 7820 and Formlabs V5 Grey for SLA, PolyJet Rigid, and RPU70 for Carbon DLS™.

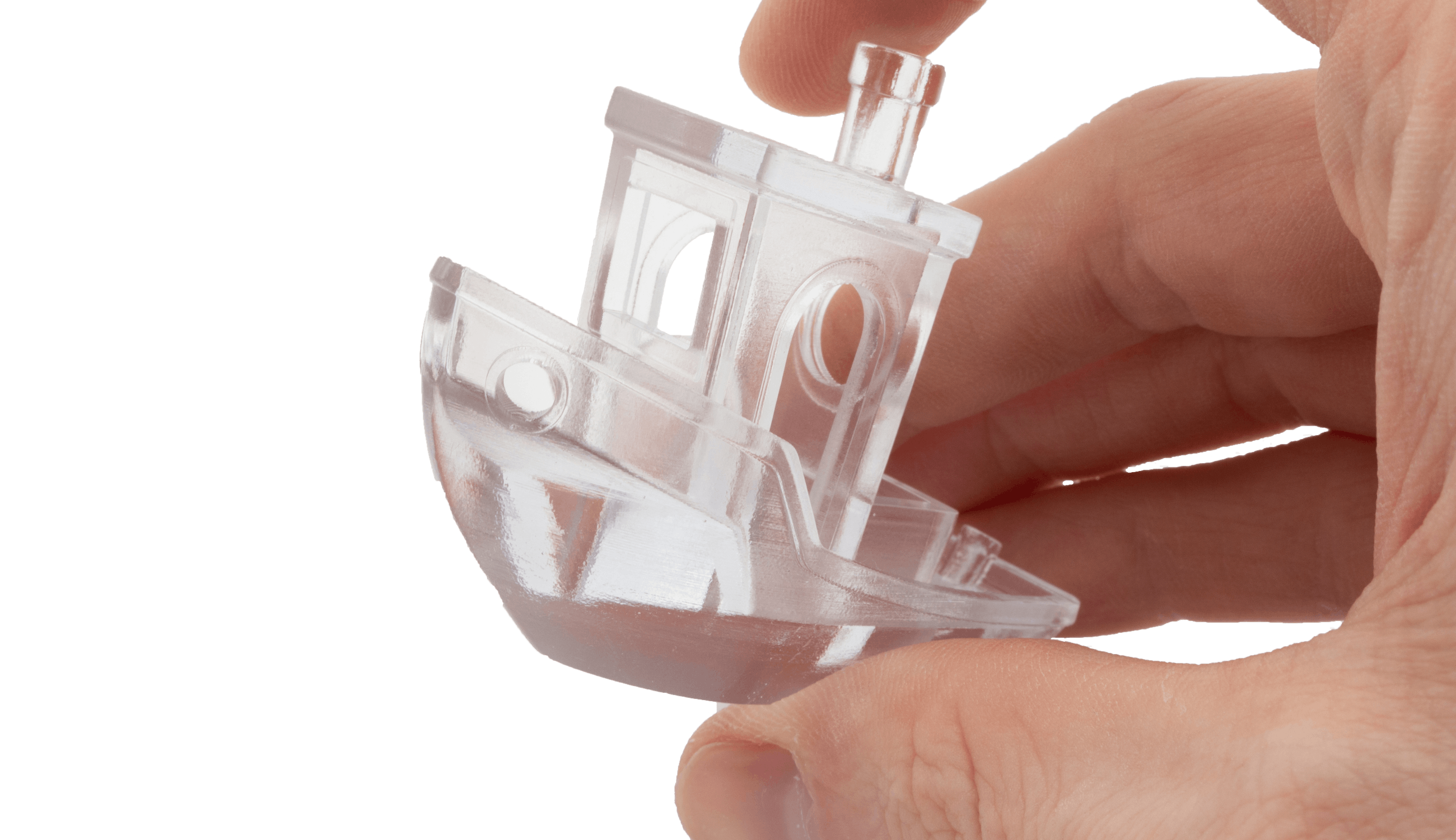

Clear Resins

Clear resins are selected for applications where transparency and optical clarity are important. They are commonly used to produce see-through prototypes, flow models, and parts that require light transmission. Some formulations achieve high optical clarity suitable for lens prototypes or fluidic demonstrations, especially when paired with our "Quick-Clear" finish. Clear resins allow designers and engineers to visualize internal features and fluid flow while maintaining the precision and surface quality typical of resin-based 3D printing.

Notable clear resins include Accura ClearVue, Formlabs Clear V5, and Somos WaterClear Ultra 10122, all of which are available for SLA printing.

Durable and Tough Resins

Our durable and tough resins are engineered for functional prototypes and end-use parts that need high impact resistance and resilience. They are ideal for applications where parts must withstand repeated handling, mechanical stress, or moderate loads while maintaining dimensional stability.

Examples of these materials include Accura Xtreme Grey & White, Somos EvoLVe 128, Formlabs Tough 1500 & Tough 2000 for SLA, and FPU 50 for Carbon DLS™.

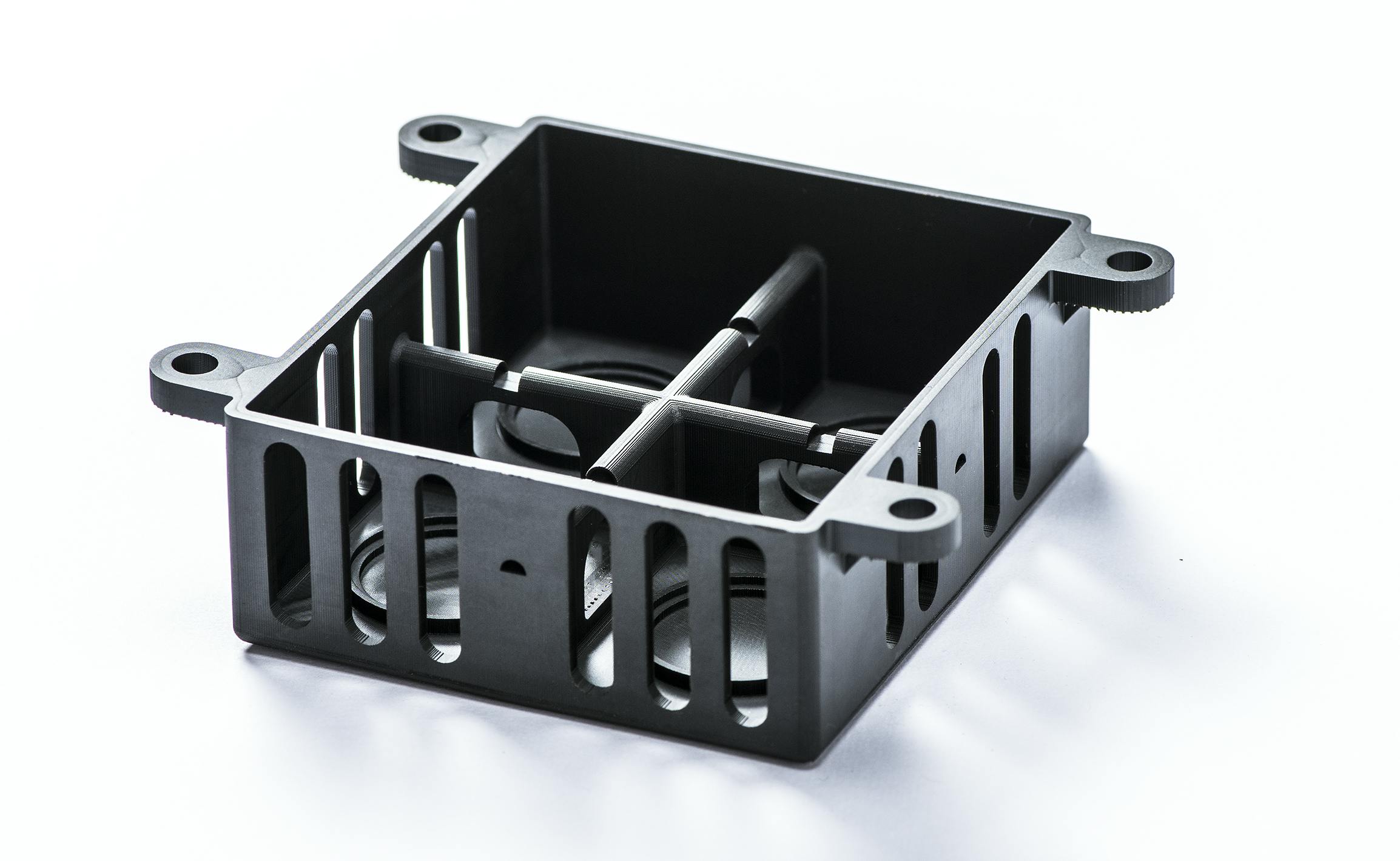

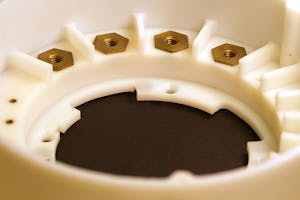

Composite and Specialty Resins

Composite and specialty resins are intended for applications that push beyond the limits of standard resins. This category includes high-stiffness composites reinforced with glass or ceramic fillers, materials engineered for high thermal resistance, and specialty formulations such as ESD-safe resins for static-dissipative fixtures. Resins in this class, like Accura Bluestone, Somos PerFORM, Formlabs Rigid 10K, and Formlabs ESD, are ideal for functional prototypes, demanding end-use parts, and specialized engineering applications where strength, durability, or unique material properties are critical.

Flexible and Elastomeric Resins

Flexible and elastomeric resins are designed to replicate the properties of rubber, offering high elasticity, elongation, and impact absorption. These materials are ideal for soft-touch prototypes, seals, gaskets, wearable devices, overmolds, and damping components. Our PolyJet Rubber-Like material is particularly versatile, allowing us to simulate a range of durometers from Shore A 30 to Shore A 95, enabling designers to create parts with varying softness or rigidity within a single prototype. Other examples include Carbon DLS™ EPU 40, providing resilient, flexible parts suitable for functional prototypes and soft end-use components, and SIL 30, a silicone-like elastomer optimized for applications requiring chemical resistance or temperature durability. These resins allow engineers to produce parts that bend, stretch, and compress while maintaining dimensional integrity.

Resin 3D Printing Advantages

Resin 3D printing offers several key benefits, making it a preferred choice for applications requiring precision, aesthetics, and functional versatility. Advantages include:

- High Resolution & Fine Detail

- Ultra-Smooth Surface Finish

- Exceptional Accuracy

- Material Versatility

- Ideal for Prototyping

High Resolution & Fine Detail

With layer heights as fine as 25 microns (0.025 mm), resin printers can capture extremely fine details and produce complex geometries. This makes them especially effective for small, intricate parts or components that must meet tight design constraints, such as those found in aerospace, robotics, and consumer electronics.

Ultra-Smooth Surface Finish

Thanks to the resolution of resin-based printing processes, parts come out naturally smooth and have high-quality surfaces with minimal visible layer lines. This reduces the need for extensive post-processing, such as sanding, and is ideal for parts that must look professional, aerodynamic, or ergonomic straight off the printer.

Exceptional Accuracy

Resin printing technologies can consistently deliver tolerances within ±0.1 mm, ensuring parts closely match digital designs. This level of accuracy allows for reliable prototypes and components that fit seamlessly into assemblies.

Material Versatility

From rigid and tough resins to heat-resistant, flexible, and specialty engineering formulations, resin 3D printing offers various options to match different performance needs. This flexibility supports both early-stage prototypes and functional test parts.

Ideal for Prototyping

Resin printing enables fast turnaround on design iterations, allowing teams to move from concept to physical parts quickly. These processes can produce prototypes that are visually representative of final production quality, making them valuable for stakeholder presentations and user testing. The ability to create functional parts with specialized resins means prototypes can also be used for limited performance testing, such as evaluating snap-fits, load-bearing designs, or high-temperature applications before committing to full-scale manufacturing.

Resin 3D Printing Industries and Applications

Resin 3D printing enables the production of precise, patient-specific parts directly from digital scans. In these fields, it is widely used for surgical guides, dental aligner models, anatomical models, and custom hearing aid shells, where accuracy and speed are essential.

Resin 3D printing supports rapid iteration and precision in automotive design and engineering. It is commonly used to create prototype housings, custom jigs and fixtures, fluid flow test models, and interior component mock-ups, helping teams validate form, fit, and function before moving to production.

Resin printing creates high-precision, lightweight parts that are critical in aerospace prototyping and testing. Typical applications include complex ducting and fluid flow models, instrument housings, aerodynamic test components, and custom tooling.

Fast, precise prototyping helps bring consumer products from concept to reality. Common uses of resin 3D printing include consumer electronics prototypes, ergonomic grips, and small-batch custom parts, allowing designers to test form, function, and aesthetics before full-scale production.

Detailed physical models help architects and designers communicate complex concepts. Resin printing is often used for architectural models, scale building prototypes, and concept mock-ups, providing high-resolution detail and realistic representations of final structures.

Why Choose Xometry for Resin 3D Printing?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get started with our easy-to-use platform, and let our experts manage the project, from locating the right manufacturing partner to delivery logistics.

Vetted Network

We are ISO 9001:2015, ISO 13485, IATF 16949, and AS9100D certified. Only the top shops that apply to become suppliers make it through our qualification process.

Alternatives to Resin 3D Printing

Selective Laser Sintering (SLS) 3D Printing Service

Fused Deposition Modeling (FDM) 3D Printing Service

Urethane and Silicone Casting Services

Custom Online CNC Machining Services

Frequently Asked Questions About Resin 3D Printing

What Is the Difference Between SLA, DLP, and Carbon DLS?

All three technologies use light to cure liquid resin, but they differ in how the light is applied and the resulting speed and material properties. SLA (Stereolithography) uses a precise UV laser that moves point-by-point across the resin surface to cure each layer, producing very precise parts. DLP (Digital Light Processing) cures entire layers at once using a digital projector, often making it faster than SLA. Carbon’s DLS (Digital Light Synthesis) is a specialized variant of DLP that uses continuous light and oxygen-permeable optics to cure parts rapidly and with isotropic mechanical properties, enabling stronger, functional parts suitable for end-use applications.

What File Formats Do I Need To Get A Quote?

Xometry supports a wide range of file formats for instant quoting. We can work with native solid models, such as .SLDPRT,.STEP,.IPT,.PRT, and other common formats. We also support 3D printing-friendly mesh-based formats such as .STL and .3MF. However, we recommend supplying native solid models whenever possible, as these allow our build planners to create high-resolution mesh files from your CAD for printing purposes. For full-color resin prints using PolyJet 3D printing, .3MF should be used.

How Does Resin 3D Printing Compare To FDM?

Resin 3D printing offers higher resolution, finer detail, smoother surfaces, and better dimensional accuracy than FDM. FDM is generally faster for larger, less detailed parts and uses a wider variety of thermoplastic materials, but resin excels for small, intricate components, prototypes, and parts requiring a professional finish.

What Are The Typical Tolerances You Can Hold?

Resin-based 3D printing processes are generally very accurate and can hold tight tolerances. However, the specific standards and tolerances vary slightly by process. To learn about the specifics for each process, consult our Manufacturing Standards page.

What Is The Maximum Part Size You Can Print?

For resin prints, the maximum part size is primarily dictated by the specific printing process, material, and resolution. Of our resin printing processes, standard resolution SLA has the largest available build envelope, around 29” x 25” x 21”.

Our FDM printing process can support prints up to 36" x 36" x 24" for larger, non-resin parts.

Is Resin 3D Printing Suitable For Functional Parts?

Yes! Resin printing can produce functional and end-use parts, but suitability depends on the technology. SLA works well for prototypes and detailed parts, while Carbon DLS is ideal for strong, end-use components thanks to its isotropic mechanical properties and engineered materials. PolyJet is generally not recommended for highly functional or load-bearing parts due to the fragile nature of its materials.

Can Resin 3D Printed Parts Be Post-Processed?

Yes, resin 3D prints can be effectively post-processed in a multitude of ways, depending on what you need. At Xometry, we offer several finishing options for SLA parts, from natural or matte finishes to our "Quick-Clear" finish, which enhances the transparency of clear resins. You can see examples of each in our 3D Printing Materials & Finishes photo gallery.