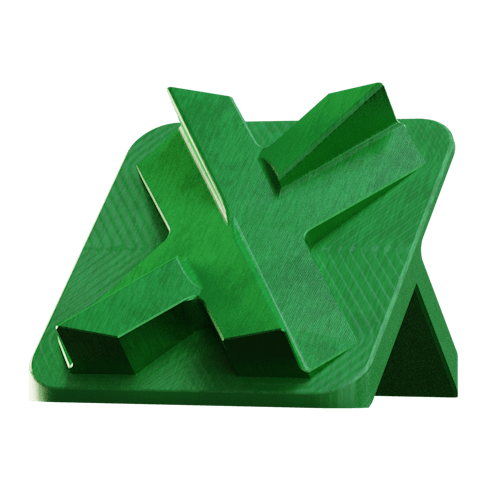

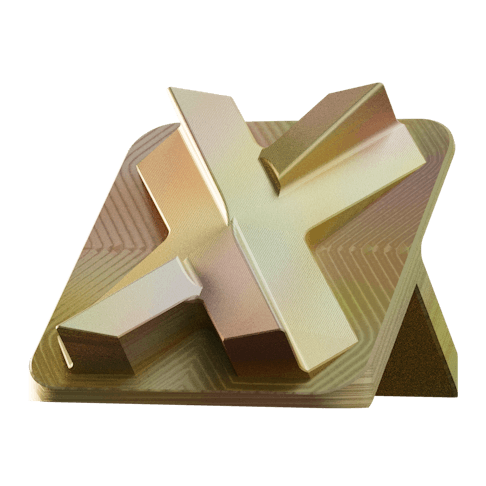

6061 Aluminum Metal

6061 Compatible Capabilities

Custom CNC Milling Services

CNC Turning Service

Custom Online Laser Cutting Service

| Material Properties | Value |

|---|---|

Material Properties Hardness, Vickers | Value 107 |

Material Properties Hardness, Rockwell A | Value 40 |

Material Properties Hardness, Rockwell B | Value 60 |

Material Properties Hardness, Knoop | Value 120 |

Material Properties Hardness, Brinell | Value 95 |

Material Properties Elongation at Break | Value 12% |

Material Properties Modulus of Elasticity | Value 10,000 ksi or 68.9 Gpa |

Material Properties Tensile stress | Value 42,000 psi or 290 Mpa |

Material Properties Yield stress | Value 35,000 psi or 241 Mpa |

Material Properties Ultimate bearing stress | Value 88,000 psi or 607 Mpa |

Material Properties Fatigue stress | Value 14,000 psi or 96.5 Mpa |

Material Properties Poisson's Ratio | Value 0.33 |

Material Properties Shear stress | Value 30,000 psi or 207 Mpa |

Material Properties Shear modulus | Value 3770 ksi or 26 Gpa |

Material Properties Machinability | Value 50% |

Material Properties Thermal Conductivity | Value 167 W/m-k |

Material Properties Specific heat capacity | Value 0.896 J/g-°C |

Material Properties Melting Point | Value 582–652 °C |

Material Properties Density | Value 2.7 g/cc |

Material Properties Artificial Aging Temperature | Value 160 °C |

Material Properties Solution Aging | Value 529 °C |

Finishes

- Bead Blast

- Tumbled

- Type II

- Type III Hardcoat

- Clear Chem Film

- Gold Chem Film

- Nickel

- Zinc

- Gold

- Silver

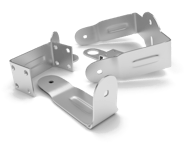

Applications of 6061 Aluminum

Structural components

Medical devices

Aerospace components

6061 Aluminum's Frequently Asked Questions

Can 6061 aluminum be bent?

Yes, 6061 can be bent, however its common temper 6061-T6 aluminum (found in many machine shop stocks) makes it much more prone to failure due to increased brittleness, and so it is recommended to bend this aluminum alloy in its untempered or in its annealed state.

Can 6061 aluminum be welded?

Yes, 6061 aluminum is routinely welded, however it can experience solidification cracking if mishandled. Using filler material such as 4043 aluminum and 5356 aluminum is highly recommended.

Why use 6061 aluminum alloy?

6061 aluminum has a fantastic blend of characteristics for both general and application-specific applications; it is relatively cheap, strong, workable, machinable, weldable, able to be heat-treated, resistant to corrosion, and can be polished to an aesthetic finish.

Which aluminum is stronger, 6061 or 6063 aluminum?

It depends on the temper, application, and environment, but generally speaking 6061 aluminum has a higher yield strength ans fatigue strength than 6063 aluminum.

How is 6061 aluminum made?

6061 aluminum is an alloy blend of several elements such as silicon, magnesium, chromium, manganese, zinc, iron, titanium, copper, and other elements with a majority composition of pure aluminum (typically >97%). It is made by mixing pure aluminum with the right ratio of these alloying elements in a foundry.

What is 6061 aluminum used for?

Being one of, if not the most popular aluminum grade, 6061 aluminum is used for a huge range of applications, including structural components, aerospace and automotive frames, rivets and fasteners, flooring, boat parts, and many other uses.