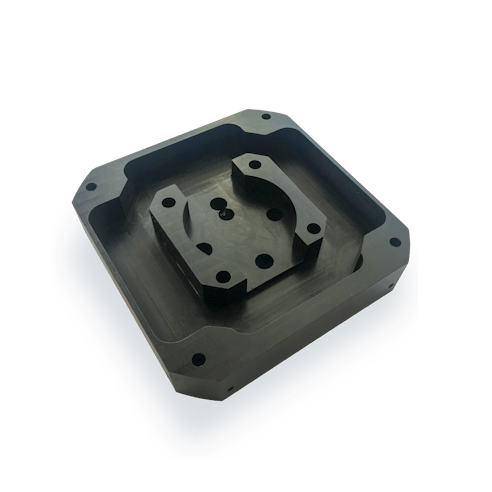

Acetal (Delrin) CNC Machining

Acetal is a high-strength thermoplastic also known by its brand names, Delrin®, Tecaform® and Sustarin®. It has exceptional mechanical properties and temperature resistance when compared to other, more common plastics. It is easy to machine and has excellent dimensional stability. This combination of properties makes CNC machining in Delrin perfect for high-precision mechanical components such as gears and bearings. Delrin parts can be found in consumer electronics such as printers and televisions.

Acetal CNC Machining

Delrin is the DuPont trade name for homopolymer acetal. It has better mechanical properties than acetal copolymer with a notable improvement in impact resistance. In addition to its exceptional mechanical properties, CNC machined acetal offers superior dimensional stability that makes it ideal for high-precision parts.

| Applications | Advantages | Disadvantages | Lead Time | Price | Tolerances |

|---|---|---|---|---|---|

Applications High-precision mechanical parts such as bearings, bushings, gears, and valve components | Advantages Good fatigue resistance, low friction, good overall toughness, moisture resistant | Disadvantages Centerline porosity, limited chemical resistance, tendency to creep under constant load | Lead Time Starting at 3 days | Price Medium ($$) | Tolerances Standard ±0.010"; ±0.001" are achievable; sub-±0.001" are available after manual review |

Delrin 150

Due to its high impact resistance and low friction characteristics, CNC-machined Delrin is ideal for gears, door system components, and bushings. It is a lightweight and cheap alternative to metal parts and, in many ways, bridges the gap between plastics and metals. Delrin can also maintain its properties across a temperature range of -40C to 120C, which is a much bigger range than most other plastics can tolerate.

| Tensile Strength, Yield (MPa) | Elongation at Break (%) | Hardness (Rockwell M) | Heat Deflection Temperature (°C) at 0.46 MPa | Melting Point (°C) |

|---|---|---|---|---|

Tensile Strength, Yield (MPa) 73-76 | Elongation at Break (%) 25-45 | Hardness (Rockwell M) 94 | Heat Deflection Temperature (°C) at 0.46 MPa 160-169 | Melting Point (°C) 175-178 |

Note: For reference only. Values can vary slightly depending on the grade and manufacturer.

Delrin 100 (AF)

Delrin 100 AF is a Delrin blend infused with PTFE (Teflon) fibers to enhance the wear resistance and low-friction properties of the material. This makes the material especially suitable for applications that require low wear or low friction, such as with bearings. The PTFE fibers also help improve the strength, toughness, and dimensional stability of the material.

| Tensile Strength, Yield (MPa) | Elongation at Break (%) | Hardness (Rockwell M) | Heat Deflection Temperature (°C) at 0.46 MPa | Melting Point (°C) |

|---|---|---|---|---|

Tensile Strength, Yield (MPa) 53-56 | Elongation at Break (%) 10-19 | Hardness (Rockwell M) 77 | Heat Deflection Temperature (°C) at 0.46 MPa 160-169 | Melting Point (°C) 175-178 |

Note: For reference only. Values can vary slightly depending on the grade and manufacturer.

Finishes

As is the case with most plastics for machining, acetal parts can only accept a few types of surface finishes. Below are our main surface finishing options for CNC-machined acetal/Delrin components.

As Machined: It is possible to create an excellent surface finish fresh from the CNC machine. Xometry manufacturers achieve this using sharp HSS (high-speed steel) cutting tools with appropriate high rake and relief angles.

Bead Blast: Tool marks are generally noticeable on CNC-machined acetal or Delrin parts. Bead blasting can be performed to mitigate tool marks. It is important to note that surface color will lighten with bead blasting, causing black materials to appear dark gray after processing.

Cost-saving Design Tips

Acetal (Delrin) is one of the more expensive plastics on the market, so it is important to follow the cost-saving principles below.

Design to standard sizes: Acetal is typically supplied in sheets of standard thicknesses or in extruded forms such as solid bars. Ensuring your part fits within standard stock sizes can help reduce material waste and avoid custom stock orders, which increase cost and lead time.

Do not aim for minimum wall thickness: Although achievable, minimum wall thicknesses may be difficult to fixture and reproduce without flex, warp, or chatter, and can drive pricing up. We do not recommend going below 0.060"-0.080" in wall thickness for acetal components.

Find more design tips in our CNC Machining Design Guide.