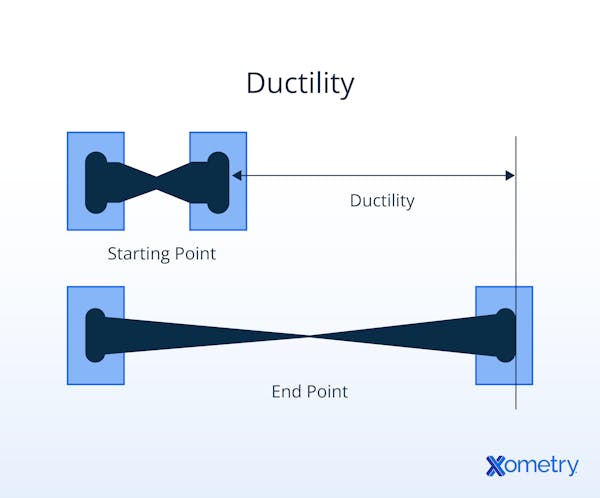

Ductility is a material's ability to undergo significant plastic deformation before fracturing when subjected to tensile stress. Engineers use standardized tests to quantify this characteristic. In these tests, a gradually increasing tensile force is applied to the specimen until it fractures or reaches a defined failure point.

This knowledge is essential in fields like engineering, manufacturing, and construction, where a material’s response to stress can have dire implications. An accurate ductility test can be part of a research and development effort, function as a quality assurance indicator, or tell you whether a material is appropriate for use in a particular application. This article will define ductility testing and discuss its purposes, applications, and procedures.

What Is a Ductility Test?

A ductility test is a mechanical evaluation method used to quantify how much a material can plastically (and permanently) deform under tensile stress before failure. It establishes the maximum amount of deformation the material can withstand before cracking or breaking. This test is essential for determining the durability, effectiveness, and suitability of materials for stress-inducing applications.

Ductility testing has a long history, dating back to ancient times when metalworkers discovered the properties of malleable and ductile metals such as gold, silver, and copper. Over time, as metallurgy improved, new techniques were developed to make use of metal’s ductility. Long-lived techniques like forging metal with a hammer or drawing wire through a die depend on this property.

Keith Millis, an American metallurgical engineer, played a key role in the development of ductile iron in the 1940s. During World War II, he was tasked with finding alternative ways to strengthen iron for use in weapons production. Millis and his team discovered that adding magnesium to molten iron caused graphite to form as spheroidal nodules, which significantly improved ductility and toughness. This discovery revolutionized the iron industry and led to the widespread use of ductile iron thereafter.

How Does Ductility Testing Work?

Ductility testing is typically conducted using a tensile testing machine, which applies an increasing tensile load to a material specimen until it undergoes plastic deformation or fractures. Test specimens are often standardized cylindrical or flat specimens and are gripped at both ends in the tensile testing machine. The load is applied until the specimen either fractures or reaches a specified elongation or strain limit, depending on the test criteria. The permanent deformation, often expressed as a percentage of the original gauge length, defines the material's ductility and is commonly reported as percentage elongation.

What Is the Purpose of Ductility Testing?

The purpose of ductility testing is to determine a material’s ability to undergo plastic deformation under tensile stress without fracturing. This test is important in evaluating the quality and suitability of materials for various applications. For instance, ductility testing can tell a construction engineer whether their steel is pliable enough to withstand seismic activity. In manufacturing, ductility testing can help assess a material’s suitability for forming operations, though malleability specifically refers to deformation under compressive stress.

When Are Ductility Tests Used?

Ductility tests are commonly employed in materials science and engineering to evaluate whether a material is suitable for specific applications, including manufacturing and construction. These tests are especially important for materials like wires and cables, which are subjected to tensile stress during installation and use. In a ductility test, a material sample is usually stretched until it fractures. These tests help engineers determine if a material can meet performance requirements in real-world conditions, such as resisting tension or accommodating stretching without cracking. This result provides insight into the material’s mechanical behavior and its fitness for intended applications.

Where Are Ductility Tests Applied?

Here are some instances of how and where ductility tests are used:

- Metallurgy: Testing for ductility is done on a variety of metals, including steel, copper, and aluminum. The tensile test, which measures how much plastic strain a metal can undergo before fracture, is among the most critical methods for evaluating ductility in metallurgy.

- Civil Engineering: Ductility tests help assess the qualities of building materials like concrete and asphalt. While flexural tests assess bending performance, they are more commonly used to evaluate the flexural strength of materials like concrete or asphalt, rather than ductility. Tensile tests are not typically used for brittle materials like concrete.

- Automotive Industry: Ductility tests are used to evaluate the quality of automotive components such as sheet metal (and the welds that hold it together). In the automotive industry, ductility is often evaluated using tests like the Erichsen cupping test, which assesses a material’s ability to undergo plastic deformation without cracking, especially for sheet metals. Though vehicles are often subject to unpredictable forces, the metal body should be designed in such a way that it can be bent without breaking.

- Aerospace Industry: Ductility tests are used to evaluate the properties of materials like the titanium and composites used in aircraft. In the aerospace industry, tensile tests are the primary method for evaluating ductility, particularly for metals like titanium. Compression tests assess other mechanical properties but are not typically used for ductility.

- Materials Research: Material properties can be improved if they’re fully understood. Researchers use a range of standardized ductility tests, including tensile, bend, and impact tests, to evaluate new materials or modifications to existing ones.

How to Perform Ductility Tests?

Listed below is a step-by-step guide on how to perform a basic ductility test:

- Sample Preparation: Prepare the material specimen according to the relevant standard. This may involve cutting or machining it into a specific shape and size.

- Test Apparatus Setup: Set up the test apparatus according to the specifications of the test method you aim to use. This may involve mounting the sample on a device such as a tensile testing machine.

- Pre-test Measurements: Measure the length and width of the sample before the test begins. Record these measurements — they will be needed when you calculate the percentage elongation of the sample.

- Application of Load: Apply a steadily increasing load to the sample until it begins to deform. The load application will depend on the type of ductility test you’re running.

- Deformation Measurement: Measure the amount of deformation that occurs as the load is applied. This may involve measuring the length or width of the sample at regular intervals during the test.

- Failure Identification: Continue applying the load until the sample breaks or fractures. Identify the point at which the sample fails.

- Post-Test Measurements: After the test, measure the final gauge length of the fractured specimen to determine how much it has elongated. Record this measurement for later use in calculating the percentage elongation of the sample.

- Calculation of Percentage Elongation: This value indicates the degree of ductility of the material.

What Are the Ductility Test Procedures?

The procedures vary depending on the specific ductility test. Here are some common procedures:

- Tensile Test: A tensile test, also known as a tension test, is a mechanical test used to determine various mechanical properties of a material, including its strength and ductility. A tensile testing machine applies a uniaxial load to stretch a standardized specimen until fracture, measuring how much plastic and total strain the material can endure. The specimen elongates and undergoes necking in the gauge region before ultimately fracturing as the tensile load increases. Test data from a tensile test can be used to determine a material’s ultimate tensile strength, yield strength, elongation (ductility), reduction of area, and Young’s modulus.

- Flexural Test: Flexural testing subjects the specimen to compressive stress on one side and tensile stress on the other, with minor shear stress depending on specimen thickness and span-to-depth ratio. The geometry of the specimen and the rate at which the load is applied, in addition to the material properties, impact the test's outcomes. A sample of the material is placed on two supports during a flexural test, and the sample's center is loaded. The sample will bend as the load is increased, and the degree of bending is measured. Flexural strength and flexural modulus (modulus of elasticity in bending) can be calculated by measuring the material's deflection under a specified loading condition.

- Cupping Test: A common technique for analyzing the ductility and formability of sheet metal is the cupping test. In the cupping test, a circular metal sheet is clamped over a die, and a hemispherical punch is pressed into the sheet's center until a crack appears or a specific depth is reached. The specimen deforms into a dome shape under the punch's force until failure or the maximum depth is achieved.

What Equipment is Used in the Ductility Test?

The specific test method determines what type of equipment to use. The cupping test uses a cupping machine equipped with a hemispherical punch and a matching die to evaluate the formability and ductility of sheet metals. The metal specimen is clamped between the punch and die, and the punch deforms the sheet by pushing it into the die cavity. Ductility in the cupping test is typically assessed by measuring the depth of the punch at the point of crack initiation or failure.

What Are the Common Ductility Testing Results?

Ductility tests typically tell you how much deformation a material can withstand before failing. The tensile test, the bend test, and the cupping test are the most common ductility testing procedures. Results from these tests may include:

- Elongation: The percentage increase in length of the gauge section of the specimen before fracture, relative to its original length.

- Reduction in Area: The percentage decrease in cross-sectional area at the fracture location, relative to the original area.

- Strain: The amount of deformation per unit original length, typically expressed as a dimensionless ratio or percentage.

- Stress: Stress is the internal resistance of a material to deformation, defined as force per unit area (σ = F/A), and may be measured at different stages, such as yield or ultimate strength.

- Modulus of Elasticity: The modulus of elasticity (Young’s modulus) is the ratio of stress to strain within the elastic region of a material’s deformation, indicating its stiffness.

What Are the Types of Ductility Testing?

The types of ductility testing are listed below:

1. Hardness Testing

Hardness testing measures a material’s resistance to localized plastic deformation (usually by indentation) using instruments like Rockwell, Brinell, or Vickers testers. Common hardness testing methods include Brinell, Vickers, and Rockwell, though these tests assess hardness, not ductility directly.

2. Impact Test

Impact tests measure the energy absorbed by a material during fracture and are designed to evaluate toughness, not ductility. The most common impact tests include the Charpy V-notch and Izod tests, which evaluate notch sensitivity and fracture behavior under dynamic loading.

3. Fracture Toughness Tests

Fracture toughness tests assess a material’s resistance to crack initiation and propagation, especially in the presence of pre-existing flaws. Common fracture toughness methods include the KIc (linear elastic fracture toughness) and J-integral (elastic-plastic fracture toughness) tests.

What Are the Ductility Testing Standards?

Ductility testing standards are established procedures that define how to evaluate a material’s capacity to plastically deform under tensile stress before fracture. The most common standards for ductility testing are:

- ASTM E8/E8M-21 (Standard Test Methods for Tension Testing of Metallic Materials): This standard provides guidelines for the tensile testing of metallic materials, including the measurement of ductility.

- ASTM D638 (Standard Test Method for Tensile Properties of Plastics): This standard outlines the procedures for testing the tensile properties of plastics.

- ISO 6892-1:2016: This international standard specifies the methods for tensile testing of metallic materials at room temperature.

What Are the Benefits of Ductility Tests?

The benefits of conducting a ductility test include:

- Understanding the behavior of your material under tensile stress.

- Identification of material defects or weaknesses.

- Determination of material properties such as elongation and reduction in area.

- Quality control in your manufacturing processes.

- Ensuring compliance with industry standards and regulations.

What Are the Limitations of Ductility Tests?

The limitations of ductility tests are:

- Measurements are limited to the deformation prior to fracture and can be influenced by factors like specimen size, temperature, and strain rate.

- Testing accuracy may be compromised by machine calibration errors, misalignment, or gripping issues.

- Difficulties in obtaining representative samples.

Common FAQs on Ductility Testing

Are Ductility Tests Accurate?

Yes, ductility tests can be accurate when performed properly and under appropriate conditions. However, accuracy depends on proper calibration of equipment, consistent environmental conditions, and technician expertise in sample preparation and test execution. It is important to follow established testing procedures and to properly calibrate and maintain the testing equipment to ensure accurate results.

What Is the Difference Between Tension Testing and Ductility Testing?

Tensile testing is a general category of mechanical testing in which materials are subjected to a uniaxial tensile load to evaluate properties like strength, ductility, and modulus. Ductility testing is a specific outcome of tensile testing that measures how much a material can plastically deform before fracture, typically expressed as elongation or reduction in area.

Summary

This article presented ductility testing, explained it is, and discussed the purpose of this test. To learn more about ductility tests, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including 3D printing and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.