Case Study: KPM Analytics Turns to Xometry’s Instant Quoting Engine for a Quick and Affordable Custom Part

When the analytical equipment manufacturer needed a quick fix for augmenting an existing machine, it worked with Xometry to order a 3D-printed part that measured up.

| Industries | Manufacturing Services Utilized | Project Brief | Solution |

|---|---|---|---|

Industries Analytical equipment for the food sector | Manufacturing Services Utilized HP Multi Jet Fusion | Project Brief KPM Analytics wanted to test a new system to measure the height of cookies on a conveyor belt and needed a quick way to mount a laser inside of one of the company’s existing instruments. | Solution Using Xometry’s Instant Quoting Engine, KPM Analytics uploaded a design for the laser mount and had a custom part 3D-printed using HP Multi Jet Fusion. |

KPM Analytics provides premium quality assurance equipment to food producers all over the world, helping them analyze the composition of their products. When the company needed to augment one of its existing instruments so it could measure the height of cookies on a conveyor belt, engineer David Malaguti came up with a solution to add a small mount inside the machine that could hold the measuring device.

HP Multi Jet Fusion: Fast and Flexible

Malaguti knew he wanted the speed and flexibility of 3D printing when creating the part, and a recommendation from another KPM engineer led him to Xometry.

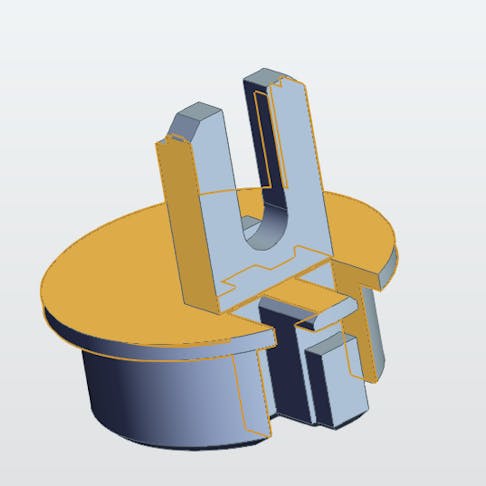

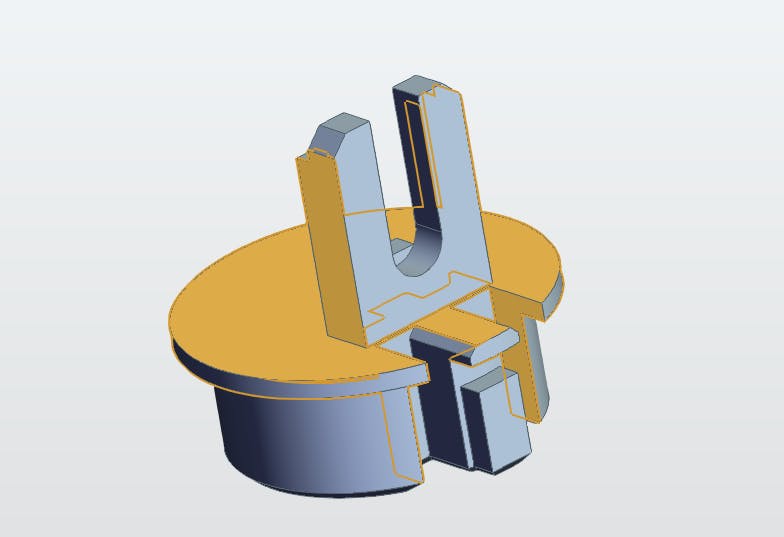

To create the part, Malaguti chose HP Multi Jet Fusion from the processes available on the Xometry Instant Quoting Engine®. MJF is a powerful 3D printing technology that creates accurate and durable parts at fast speeds. The powder-based 3D printing process builds parts layer by layer, using a fusing agent and heat to set each layer before moving on to the next. Using this technology allowed Malaguti to create a very detailed part with a lot of features that would have been much more expensive to make using another method.

“This part would have been hundreds of dollars to machine. The comparison was not even apples to apples,” Malaguti said. “Essentially, features are free, as long as you stay in the same envelope size. That's pretty cool.”

Xometry's HP MJF printing service has a recommended build envelope of 15” x 11” x 15”, which gave Malaguti plenty of room to fit in all the necessary features.

For the material, he chose to make the part out of Nylon 12.

”I scrolled through and quoted different materials and that seemed like it was a good fit,” he said. “It's a good material. It was strong enough. It didn't need to be very strong, in this case, but it needed to not melt.”

You Too Can Get an Instant 3D Printing Quote from Xometry

Xometry provides 24/7 access to instant quoting and manufacturing feedback on 3D printed parts in a variety of printing processes, including:

- Fused Deposition Modeling (FDM)

- Selective Laser Sintering (SLS)

- HP Multi Jet Fusion (HP MJF)

- Stereolithography (SLA)

- PolyJet 3D

- Carbon Digital Light Synthesis™ (DLS™)

- Direct Metal Laser Sintering (DMLS)

- Metal Binder Jetting (BJ3D)

Instant Quotes, Reliable Results

Using the Xometry Instant Quoting Engine allowed Malaguti and his team to obtain a quote quickly and move through the production process smoothly. After uploading the design, he had the finished part in hand in just a few days.

In addition to the ease of instant quoting, Malaguti said the quality of the finished product would make him feel good about sending more custom manufacturing jobs to Xometry.

“They haven't let us down. They've done exactly what they've said they would do,” he said. “When the due date comes, you need the actual parts instead of a story.”