Casting is one of the oldest known metallurgical techniques. Historically, the first functional metal components were made from copper, accidentally extracted from chalcopyrite and chalcocite ores in open fires. The molten copper could be poured into natural depressions or molds in the ashes, forming ingots that were later hammered into useful shapes. Aluminum casting refers to a group of manufacturing processes in which molten aluminum is poured into a mold to create a desired shape. It is critically important for producing complex, net-shape or near-net-shape parts in a single stage, transforming liquid metal directly into a finished or semi-finished product. Because aluminum is lightweight, corrosion-resistant, and highly versatile, casting is widely used to create components for automotive, aerospace, industrial machinery, and consumer products.

This article will explain what aluminum casting is, how it works, its industrial significance, the main types of casting processes, and their key applications.

What Is Aluminum Casting?

Aluminum casting is the process of introducing molten aluminum into a cavity to create a part. Aluminum and many of its alloys have relatively low melting points and low viscosity when molten, yet cool to form strong, rigid solids. A variety of casting processes use these properties by forming a heat-proof cavity (in one or two parts), into which molten aluminum is poured. The metal then cools and solidifies, taking on the shape of the cavity it has filled. The cavities used for this vary in material and construction, and the processes have various names.

Why Is Aluminum Casting Important?

Aluminum casting is a core manufacturing technology within the aluminum product supply chain, enabling the production of complex, high-precision components.

Human technological development has progressed through a series of material-driven transitions. The Bronze Age marked the first widespread use of metal alloys, followed by the Iron Age, in which stronger and more abundant iron replaced bronze in tools and weapons. In the 19th century, advances in metallurgy and mass production made steel the dominant structural material. By the mid-20th century, aluminum emerged as a competitive alternative in specific applications driven by the demands of the aerospace, automotive, and electrical industries, which expanded rapidly from the 1940s onward.

Aluminum is the third most abundant element in the Earth’s crust and is widely present in the form of alumina (aluminum oxide) in minerals such as bauxite. Although refining aluminum requires significant energy, the process is straightforward with modern electrolytic methods such as the Hall–Héroult process.

Aluminum’s combination of low density, corrosion resistance, and versatility makes it a key material in modern technology. Aluminum casting processes are essential for translating these properties into functional products. They allow the manufacture of net-shape or near-net-shape components with high dimensional accuracy, low weight, and moderate to high strength, depending on the alloy and casting method. This capability benefits virtually every manufacturing sector, including aerospace, automotive, consumer electronics, industrial machinery, and renewable energy.

Aluminum casting is the most common manufacturing method for producing lightweight, durable, and complex components across industries. Its versatility in alloy selection and process types allows manufacturers to balance cost, performance, and precision for diverse applications. While casting introduces considerations such as porosity and microstructural variability, proper design and process control enable high-quality results. As industries continue to demand lightweight solutions and intricate geometries, aluminum casting will remain a vital technology that bridges material properties with modern engineering requirements.

What Are the Properties of Cast Aluminum?

The aluminum used in casting generally refers to its alloys rather than pure aluminum. The properties of which are as follows:

- Aluminum alloys have a range of ductilities, typically lower than pure aluminum, which is very soft.

- Ultimate tensile strength varies with alloy type and casting process. Pure aluminum has a tensile strength of about 90 MPa, while a casting alloy such as A07130 can reach around 221 MPa. Low porosity castings produced with aggressive degassing and high-pressure casting can achieve strengths close to the alloy’s maximum potential. Some alloys are developed for higher resilience, while others are designed for greater rigidity, which can make them more brittle.

- Porosity caused by gas inclusions or cavities can significantly weaken a casting. This is a common issue in less-controlled, low-pressure casting methods.

- Cast aluminum has an excellent stiffness-to-weight ratio, exceeded only by more expensive materials such as magnesium or titanium.

- It generally offers very good corrosion resistance.

- It has excellent electrical and thermal conductivity.

What Is the Tensile Strength of Cast Aluminum?

The tensile strength of cast aluminum varies significantly depending on the alloy composition, casting method, and heat treatment condition. Pure aluminum offers the lowest strength, with a typical tensile strength of around 90 MPa. By contrast, casting alloys, which contain other elements, can have much higher strengths. For example, alloy A07130 (Al–Si–Mg type) has a tensile strength of approximately 221 MPa in the as-cast condition and even higher values if heat-treated, depending on process and standard.

How Durable Are Cast Aluminum Parts?

Aluminum castings are very tough when designed to exploit the strengths and offset the weaknesses of the process. Cast aluminum is of no use as a bearing surface or under impact loads, and must be carefully designed to handle high and cyclic loads. Aluminum castings suffer from stress cracking, creep, abrasion, and shock loading, all of which are factors to be managed in the product design process.

Is Cast Aluminum Heat-Resistant?

Yes, cast aluminum is generally heat-resistant. Cast aluminum is resistant to heat within the limits of the material, which varies considerably by alloy. For example, AlSi alloys are easily cast, resist heat cracking, and can serve up to 180 °C. For higher temperature resilience, AlCu alloys can handle 350 °C but require simpler shapes and thicker sections to cast well. AlMg alloys, on the other hand, also offer good temperature performance and better castability than AlCu but lower strength.

Different Types of Aluminum Casting Processes

Aluminum casting processes can be broken down into different types as listed below:

1. Die Casting

Die casting uses a hardened steel, two-part cavity tool, in which molten aluminum is poured or forced. These tools generally have 100,000 to 150,000 cycles of shot life and produce high-accuracy and high-quality parts. Die casting ranges from using simple tools with hand-poured fill-up to completely automated systems for very high volumes.

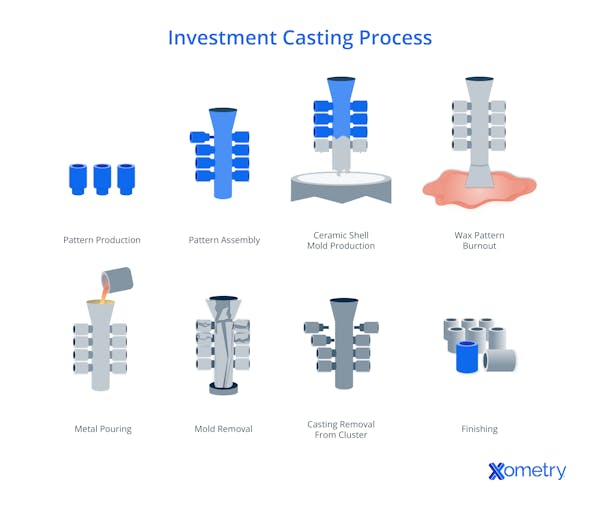

2. Investment Casting

This process uses a sacrificial positive model of the required part. Before molten aluminum is poured into the plaster form, the wax is vaporized or driven out by baking the plaster tool. The cavity retains its shape and is then filled with molten metal that cools quickly.

In a more up-to-date approach, the positive model used to cast the cavity can be cut from expanded polystyrene, or 3D printed in wax and potentially polymers such as PET and PLA. In the case of plastic “positives,” they must also be burned out of the cavity to leave no residues. This process tends to be reserved for high-value and intricate parts. The tool is destroyed to extract the finished part.

3. Sand Casting

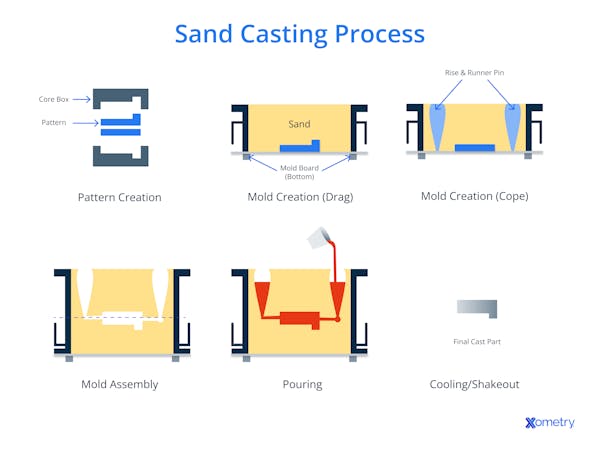

Sand casting involves using a stronger pattern part, typically made from wood, and then packing it into two box halves. This process utilizes sand with a binding agent, and talc serves as a release and separating agent. Cavities are usually filled by hand pouring, though automation is possible. This is usually referred to as sand casting and is widely employed in the manufacture of lower-volume and/or larger shot-weight castings. While good precision is possible, the destruction of the cavity tool makes this a one-shot process.

4. Permanent Mold Casting

This process is analogous to die casting in that two permanent (often cast steel) mold halves are clamped together and the cavity filled, generally by hand pouring.

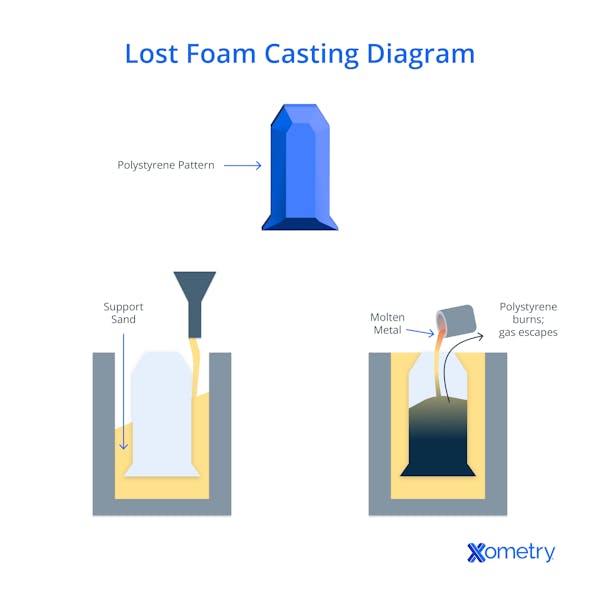

5. Lost Foam Casting

Lost foam casting is identical to investment casting. The pattern, however, is made from low-density foamed polymer rather than wax.

6. Shell Mold Casting

A refinement of basic sand casting uses resin-bonded sand cast around the pattern to form a strong shell. Two shells are fixed together to form a sacrificial (single-use) cavity that is filled with molten aluminum. This process makes casting cavities faster and at a lower cost than ordinary sand casting and is used for medium to large casts needing higher precision.

7. Vacuum Die Casting

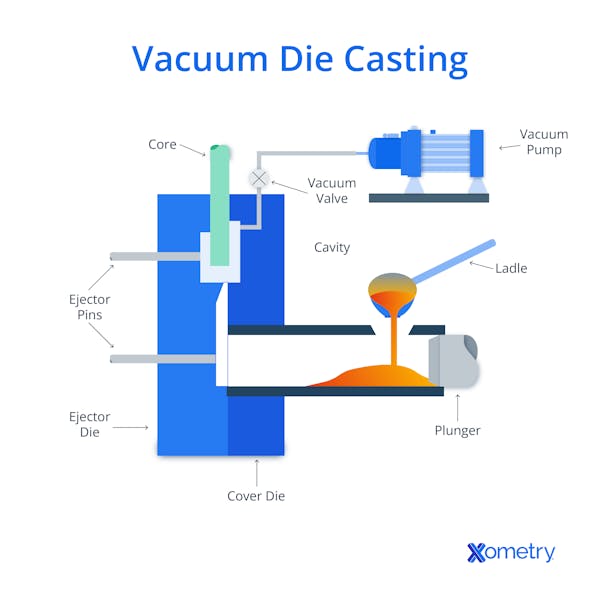

Vacuum die casting differs from pressure or gravity die casting in that it uses a reservoir below the casting tool. It pulls the molten material up by a vacuum applied to the tool. This results in lower porosity and higher-quality parts, slowly displacing older die-casting methods.

8. Ceramic Mold Casting

This process casts a silicate slurry around a pattern, and then either burns the volatiles from the slurry (Osborn-Shaw process) or bakes them off (Unicast process), leaving a ceramic cavity into which molten metal can be poured. In many regards, this process is analogous to shell mold casting.

9. Plaster Mold Casting

This process is similar to shell mold and ceramic mold casting, but gypsum plaster is used to form the cavity tool.

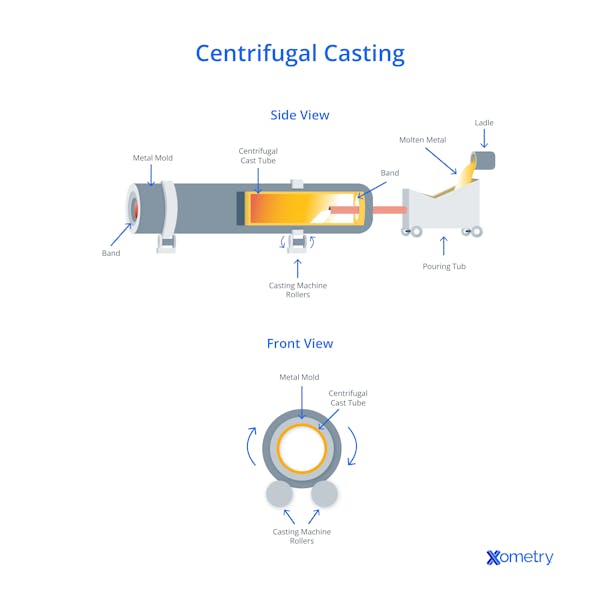

10. Centrifugal Casting

This process uses a fast-spinning steel cavity tool to cast aluminum. Larger parts with rotational symmetry lend themselves to this process. The tool is spun once filled, and centripetal force fills the extremities very cleanly, with no inclusions of porosity. Centrifugally cast aluminum is fine-grained and defect-free, with improved hardness and strength, compared with other processes. It's used for asymmetrical parts that require the best possible properties and are not cost-sensitive.

11. Open Mold Casting

Some more primitive casting in aluminum is performed using open cavities made from brick, stone, or steel, or pressed into sand. This is usually a method for producing simple billets for later forging/machining. It can be referred to as a branch of permanent mold casting.

What Are the Different Applications of Cast Aluminum?

Some examples of the different applications of cast aluminum are:

- Automotive Parts: Transmission housings, pistons, and steering knuckles.

- Small Appliances and Home Items: Hand tools, lawnmowers, cookware, and patio furniture types.

- Medical Devices: Surgical tools, monitor components, hospital bed gearboxes.

How Long Does Cast Aluminum Last?

Aluminum die-cast parts can be expected to serve indefinitely under optimum conditions. It is common for automotive die-cast aluminum parts, for example, to remain in a functional state after over 50 years in service.

What Are the Benefits of Aluminum Casting?

Aluminum die casting offers a range of benefits, including:

- High strength-to-weight ratio

- High strength

- Low weight

- Durability under variable and cyclic loads

- High precision

- Easy machining

- High-volume and automated production

- High thermal and electrical conductivity

- Low corrosion, even in marine environments

What Are the Limitations of Aluminum Casting?

Aluminum die casting has limitations, including:

- Moderate to poor fatigue resistance

- Inferior abrasion resistance

- Zero capacity as a bearing surface

- Moderate temperature vulnerability

Frequently Asked Questions About Aluminum Casting

Can 3D Printing be Used in Aluminum Casting?

No, cast aluminum cannot be used for 3D printing. However, 3D-printed patterns are increasingly used for various aluminum casting processes. This allows patterns to be more precise and manufactured faster than traditional processes. 3D printing is also the perfect way to build confidence in design validation, by enabling levels of rapid testing that cannot be achieved by any other method, before manufacturing.

Is Cast Aluminum Pure Aluminum?

Sometimes pure aluminum is cast, as are many aluminum alloys. However, in the pure state, the material has limited application, except as an electrical conductor.

What Is the Difference Between Cast Aluminum and Aluminum?

There is no difference between cast aluminum and aluminum. Cast aluminum is the same base material (aluminum) that has undergone a process. However, due to the various casting methods that exist, the cast material may have inclusions and porosity that were not present in the raw feedstock.

What Is the Difference Between Cast Aluminum and Forged Aluminum?

The primary difference between forged and cast aluminum is the crystalline structure. Casting imposes very little control on the cooling and resultant crystal growth, making crystal structure within cast parts highly variable and disoriented. This makes thicker sections lower strength, as they cool more slowly, forming larger crystals.

Forging is often performed on cast billets. The upset process disrupts the microstructure by breaking up crystals into smaller units, without creating dislocations between them. This causes the material to become both harder and stronger, to a considerable degree. It also causes a “flow” of material around obstructions and corners, which gives the crystal microstructure a “grain” that enhances strength and stress distribution.

Inclusions (non-solution contaminants such as oxide slag) are generally aggregated to some degree in cast aluminum parts, often creating severe weakness. In forged parts, any inclusions (from the billet casting process) are smashed and distributed, reducing their influence. Aluminum castings are capable of great detail and fine sections, whereas forging is a brute-force process best suited to simple shapes.

Summary

This article presented aluminum casting, explained what it is, and discussed its various applications and benefits. To learn more about aluminum casting, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including casting and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.