What are Heat Resistant Plastics?

Plastics are used across almost every industry due to their ease of manufacture, low cost, and wide range of properties. Over and above standard commodity plastics there exists a class of advanced heat resistant plastics that can withstand temperatures that others cannot. These plastics are used in advanced applications where a combination of heat resistance, mechanical strength, and corrosive resistance are necessary. This article will explain what heat-resistant plastics are and why they are so beneficial.

What is Heat Resistant Plastic?

A heat resistant plastic is generally any plastic that has a continuous-use temperature of above 150°C (302°F) or a short-term exposure resistance of 250°C (482°F) or more. In other words, the material can sustain operations at over 150°C and can survive short stints at or above 250°C. In addition to their heat resistance, these plastics often have exceptional mechanical properties that can sometimes even match those of metals. Heat resistant plastics can take the form of thermoplastics, thermosets, or photopolymers.

Plastics are made up of long molecular chains. When heated, the bonds between these chains are broken, causing the material to melt. Plastics with low melting temperatures are often made up of aliphatic rings whereas high-temperature plastics are made up of aromatic rings. In the case of aromatic rings, two chemical bonds need to be broken (compared to aliphatic rings’ single bond) before the structure breaks down. As such, it is harder to melt these materials.

Apart from the underlying chemistry, the heat resistance of plastics can be improved using additives. One of the most common additives for increasing temperature resistance is glass fiber. The fibers also have the added benefit of increasing overall stiffness and material strength.

There are many different methods of characterizing a plastic’s heat resistance. The most significant are listed below:

- Heat Deflection Temperature (HDT) - This is the temperature at which plastic will deform under a predefined load. This measure does not account for the potential long-term effects on the material if that temperature is held for extended periods of time.

- Glass Transition Temperature (Tg) - In the case of an amorphous plastic, the Tg refers to the temperature at which the material turns rubbery or viscous.

- Continuous Use Temperature (CUT) - Defines the maximum temperature at which plastic can be continuously used without significant degradation to its mechanical properties over the part’s design lifetime.

Why use Heat Resistant Plastics?

Plastics are widely used. However, why would someone use plastics for high-temperature applications when metals can sometimes perform the same functions over much wider temperature ranges? Here are some reasons why:

1. Lower Weight - Plastics are lighter than metals. They’re thus ideal for applications in the automotive and aerospace industries that rely on lightweight components to improve overall efficiency.

2. Corrosion Resistance - Some plastics have better corrosion resistance than metals when exposed to a broad range of chemicals. This can be critical for applications that involve both high temperatures and corrosive environments like those found in the chemical industry.

3. Manufacturing Flexibility - Plastic components can be manufactured using high-volume production technologies like injection molding. This results in parts that are cheaper per unit than their CNC-milled metal counterparts. Plastic parts can also be manufactured using 3D printing which allows for complex designs and greater design flexibility than could be achieved using CNC machining.

4. Insulator - Plastics can act both as thermal and electrical insulators. This makes them ideal where electrical conductivity could damage sensitive electronics or where high temperatures can adversely affect the parts’ operation.

Types of High-Temperature Resistant Plastics

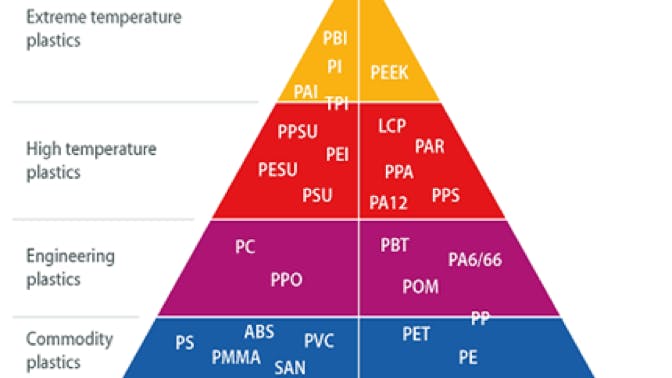

There are two main groups of thermoplastics — namely amorphous and semicrystalline plastics. Heat-resistant plastics can be found in each of these categories as indicated in Figure 1 below. The main difference between these two is their melting behavior. An amorphous material does not have an exact melting point but rather slowly softens as the temperature increases. A semi-crystalline material, by contrast, has a very sharp melting point.

Listed below are some materials on offer from Xometry. Contact a Xometry representative if you need a specific material that is not listed here.

1. Polyetherimide (PEI)

This material is often known by its trade name of Ultem and is an amorphous plastic with exceptional thermal and mechanical properties. It is also flame resistant even without any additives. However, specific flame resistance must be checked on the material’s datasheet. Xometry offers two grades of Ultem plastics for 3D printing.

| Name | 3D Printing Process | Glass Transition (°C/°F) |

|---|---|---|

Name Ultem 1010 | 3D Printing Process FDM | Glass Transition (°C/°F) 215 / 419 |

Name Ultem 9085 | 3D Printing Process FDM | Glass Transition (°C/°F) 186 / 367 |

2. Polyamide (PA)

Polyamide, which is also known by the trade name, Nylon, has excellent heat resistant properties, especially when combined with additives and filler materials. In addition to this, Nylon is very resistant to abrasion. Xometry offers a wide range of temperature-resistant nylons with many different filler materials as indicated below.

| Name | Process | Heat Deflection Temperature (°C / °F) |

|---|---|---|

Name Nylon 12 | Process FDM | Heat Deflection Temperature (°C / °F) 178 / 352.4 |

Name PA 2200 (Durable White Nylon) | Process SLS | Heat Deflection Temperature (°C / °F) 176 / 349 |

Name PA 602-CF (Carbon Filled) | Process SLS | Heat Deflection Temperature (°C / °F) 175 / 347 |

Name DuraForm GF (Glass Filled) | Process SLS | Heat Deflection Temperature (°C / °F) 179 / 354 |

Name PA 602-CF (Aluminum Filled) | Process SLS | Heat Deflection Temperature (°C / °F) 180 / 356 |

Name PA 620-MF (Mineral Filled) | Process SLS | Heat Deflection Temperature (°C / °F) 184 / 363 |

Name HP 3D High Reusability PA 12 | Process HP MJF | Heat Deflection Temperature (°C / °F) 187 / 369 |

3. Photopolymers

Photopolymers are unique plastics that become polymerized only under the effects of an external energy source like UV light or a specific optic mechanism. These materials can be used to create high-quality printed parts with complex geometries that aren’t possible with other manufacturing technologies. Within the category of photopolymers, Xometry offers two heat-resistant plastics.

| Name | Process | Glass Transition (°C/°F) |

|---|---|---|

Name Accura 48HTR | Process SLA | Glass Transition (°C/°F) 130 / 266 |

Which Heat Resistant Plastic is Best?

When it comes to choosing a heat-resistant plastic, it is important to fully understand the nature of the application. Load conditions, corrosive environments, the duration of high-temperature exposure, materials’ thermal expansion properties, etc. can all be major deciding factors. Each of these factors can dramatically change the stated mechanical and thermal properties of heat-resistant plastic and the numbers stated on a data sheet are not accurate across all possible scenarios. Contact a Xometry representative or get an instant quote to learn more about the applicability of a heat-resistant plastic to your unique application.