Unless otherwise specified, a CNC machined part will have an “as-milled” surface finish. However, many parts require additional processing to achieve a desired surface characteristic or property for cosmetic, corrosion resistance, wear resistance, or other purposes. Xometry offers a wide variety of surface finishes and treatments to ensure that your parts meet all of their surface property requirements.

Some of the most common surface finishes and treatments here at Xometry are bead blasting, anodizing, and powder coating. Take a look at the images and their descriptions below for more detail on those finishes. We also offer chem-film (conversion coating), electroless nickel, gold, or silver plating, and custom finishes. If you require a surface finish or treatment that you don't see here, please reach out to our support team (support@xometry.com) and we will be happy to help!

Standard, As-Milled Finish

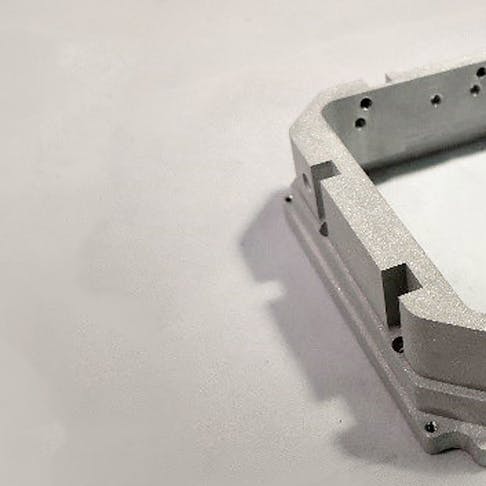

Bead Blast Finish

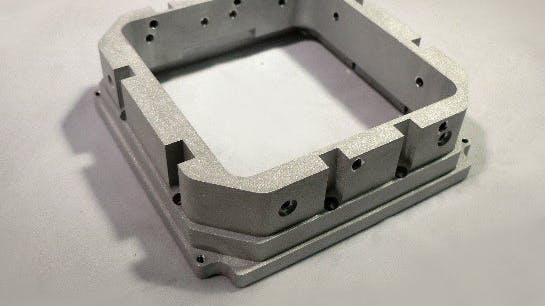

Anodizing, Type II (Sulfuric Acid Anodizing)

Type II coatings produce a uniform, corrosion resistant coating. Parts can be dyed in different colors after anodizing – black, red or gold are most common. The part shown here is not dyed. Anodizing is usually associated with aluminum parts.

Reference MIL-A-8625 for additional information on anodizing.

Anodizing, Type II (Sulfuric Acid Anodizing)

FREE CNC Metal Finishes E-Book

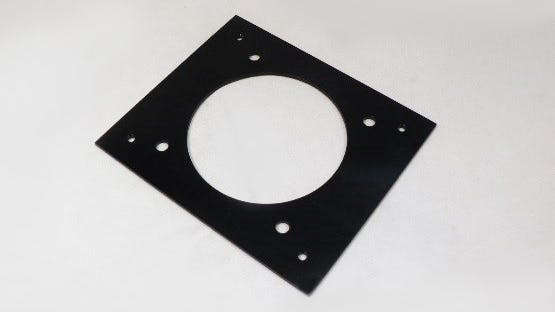

Anodizing, Type II (Sulfuric Acid Anodizing)

Type III coatings produce a wear resistant layer of specified thickness and the corrosion resistance achieved with Type II coatings. Parts can be dyed in different colors after anodizing – black, red or gold are most common. The part shown here is dyed black. Anodizing is usually associated with aluminum parts.

Reference MIL-A-8625 for additional information on anodizing.

Anodizing, Type II (Sulfuric Acid Anodizing)

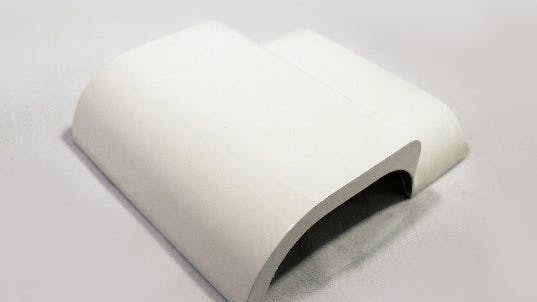

Powder Coat Finish

Powdered paint is sprayed onto a part that is then sent through an oven to bake the paint onto the part. This creates a strong, wear and corrosion resistant layer that is more durable than standard painting methods. A wide variety of colors are available to achieve the desired part aesthetic. A powder-coating finish is commonly used in military applications.

Powder Coat Finish