A copper vapor laser collides excited atoms with vaporized particles of copper to produce light wavelengths of 510 nm and 578 nm which emit green and yellow visible light respectively. Copper vapor lasers fulfill a specific application in micromachining metals and other hard materials including: diamond, glass, silica, silicon, and ceramics. The laser works by using an electrode to excite atoms in a buffer gas which then collide with vaporized copper resulting in the emission of either yellow or green light.

This article will discuss the copper vapor laser, its definition, its importance, how it works, and its properties.

What Is Copper Vapor Laser?

A copper vapor laser is also known as a neutral metal laser that uses copper vapor as a laser medium. Its primary wavelengths are 510 nm and 578 nm which produce laser light in green and yellow. This category of lasers is hard to manufacture due to the high temperatures required to vaporize copper. To overcome this difficulty, copper iodide/bromide/chloride are used as these forms of copper vaporize at lower temperatures. Copper vapor lasers are highly accurate, and so are used in micromachining, a process in which machining 1 micrometer is required.

What Is the Importance of Copper Vapor Laser?

The copper vapor laser has an important use in micromachining and cutting applications. Copper vapor lasers are the most powerful form of metal vapor lasers. They also have a unique use in photodynamic therapy which is a form of cancer treatment.

How Does a Copper Vapor Laser Work?

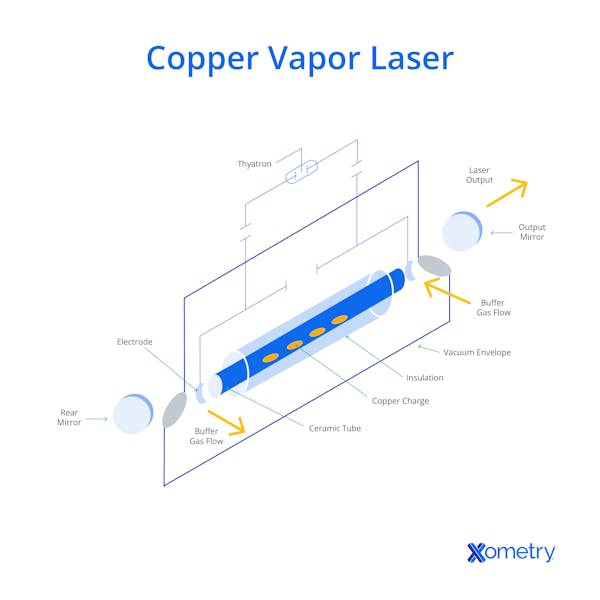

A copper vapor laser uses a refractory ceramic tube with a low-pressure buffer gas and copper pellets. Two electrodes at the end of the tube create a high-power discharge that excites some metal atoms. At the same time, the increase in temperature to around 1,450 ºC vaporizes some of the copper metal. The excited metal atoms collide with the vaporized copper atoms to produce high-energy copper atoms. These atoms then decay to produce either green or yellow light. Figure 1 is a schematic of a copper vapor laser:

What Are the Properties of a Copper Vapor Laser?

The copper vapor laser is a metal-vapor type laser that uses an electrical discharge as a pump source. The operating wavelengths for this type of laser are 510 nm and 578 nm which produce green and yellow light respectively.

What Is the Average Power and Speed of a Copper Vapor Laser?

The average power produced by a copper vapor laser is over 100 W, and some lasers can produce in excess of 1 kW. This high average output is in part due to the fast speed repetition of the pump source which can reach 100 kHz.

What Is the Type of Laser Used in Copper Vapor Laser?

A copper vapor laser uses a type of laser that is pulse-operated laser rather than a continuous wave laser. This is because the lower-energy light from the laser is slow to depopulate. For this reason, the copper vapor laser must use pulse operation to prevent the build-up of lower-energy light.

What Are the Uses of a Copper Vapor Laser?

One of the copper vapor laser’s first applications was laser isotope separation in the production of enriched uranium for reactor fuel. Other applications of the laser include:

- High-speed photography.

- Dermatological treatment.

- As a pump source for dye lasers.

- Photodynamic therapy.

How Is Copper Vapor Laser Used in Laser Cutting?

When using a copper vapor laser to remove material, the laser energy is used to either vaporize or ablate material from the surface. This is done so that the thermal effects of vaporization are retained close to the laser focal point. Additionally, the stability of the pulse energy means that the laser removes a very consistent layer of material during cutting. For more information, see our guide on How Does Laser Cutting Work.

What Are the Materials That Copper Vapor Laser Can Cut?

A copper vapor laser can be used to cut many hard materials as its wavelength is easily absorbed by metals and other hard materials. Copper vapor lasers can be used to cut various metals and the following substances:

- Diamond

- Silica

- Glass

- Silicon

- Ceramics

Additionally, doubling the frequency of a copper vapor laser allows it to produce ultraviolet light which can be used to machine plastics.

Do Copper Vapor Lasers Give a Quality Result?

Yes, copper vapor lasers provide a high-quality beam. The relative simplicity in the operation of the copper vapor laser provides a high-quality beam that facilitates its use in applications including micromachining.

Can Copper Vapor Lasers Be Used in Laser Etching?

Yes, copper vapor lasers are used in laser etching. The properties of a copper vapor laser—including its high repetition rate, high peak power, and short pulse length—lead to a fast etching ability. For more information, see our guide on What is Laser Etching.

What Are the Advantages of Copper Vapor Lasers?

Copper vapor lasers have the ability to micromachine metals whilst also minimizing heat damage to surrounding material to a submicron level. Additional advantages of using a copper vapor laser are:

- Its ability to maintain a diffraction-limited beam at high frequencies.

- The beam profile can be manipulated for specific requirements.

- The laser has high efficiency for a high power output.

- The laser has a high peak power.

- A copper vapor laser has a smaller minimum beam size when compared to CO2 and Nd:YAG lasers.

What Are the Disadvantages of Copper Vapor Lasers?

One major disadvantage of copper vapor lasers is that they are very difficult to manufacture. This is because the laser tube is required to operate at 1,500 ºC. Other disadvantages of copper vapor lasers include:

- They are very expensive in comparison to other lasers.

- They can produce dangerous smoke when cutting materials.

- Poor at cutting reflective materials.

Is a Copper Vapor Laser Expensive?

Yes, a copper vapor laser is very expensive, even in contrast to other lasers. The price of copper vapor lasers is often a major disadvantage. However, they fulfill a specific purpose in high-precision micromachining, which means for certain applications their performance advantage outweighs their high price.

What Is the Difference Between a Copper Vapor Laser and a Metal Vapor Laser?

A copper vapor laser falls into the group of metal vapor lasers. Meaning every copper vapor laser is a metal vapor laser but not every metal vapor laser is a copper vapor laser. Other forms of metal vapor laser include:

- Alkali Vapor Lasers: Alkali vapor lasers use either calcium, potassium, or rubidium which can be more easily vaporized than copper.

- Helium-Cadmium Lasers: Helium-cadmium lasers use vaporized cadmium as the laser medium. Helium-cadmium lasers emit light in the blue or ultraviolet wavelengths. Rather than cutting and photography, helium-cadmium lasers are used for spectroscopy and holography.

Summary

This article presented copper vapor laser, explained what it is, and discussed its various applications. To learn more about copper vapor laser, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including sheet cutting and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.