There are a lot of decisions and actions, small and large, that coalesce to make a laser cutting business. Regulatory requirements must meet and jurisdictional decisions need to be taken early on. Some states are very much more startup-friendly than others. Some have easier registration and compliance processes, and some areas offer geographic advantages such as: access to key markets, shipping and transport hubs, raw materials, and skilled labor. Listed below are the steps on how to start a laser cutting business:

1. Make a Business Plan for Laser Cutting

A business plan for a laser cutting company helps business owners start and manage the company. Some factors that drive depth in business planning include operational requirements, manpower needs, and financial capacity. The key to a good business plan is simple clarity, bent towards an audience.

2. Create a Legal Entity for Your Laser Cutting Business

You’re going to need a company as an operational entity. Having that set up is an advantage in most early engagements. In the US, it may be beneficial to set up in your home state, to create a local impression. If your plans are more national/international then setting up in a state with a simpler registration process can be an advantage. There are pitfalls and time bombs that can only be assessed with experience, so seeking expert advice is recommended. You may need a sole proprietorship, partnership, corporation, an S corporation, or a Limited Liability Company (LLC). Knowing which is a critical decision you’ll need to make early on.

3. Set Up a Tax Account for Your Laser Cutting Business

Wherever you register your laser cutting business, it’s critically important that you get your tax processes right to avoid major complications. Tax registration, in many jurisdictions, is an overly complex task with risks associated if you make ill-informed choices. It is safer to hand this process to a tax professional or accountant.

4. Create a Business Bank Account and Credit Card

Business banking is generally easy if you’re not looking for credit facilities. And with no operational accounts and no profit measurable yet, credit facilities will likely not be available. Get a recommendation from a bank, and ideally a contact who is ready to help and advise you. If you have significant funds to deposit, such as pre-agreed bank business lending, your own working capital, or investors’ funds, the banks will be a lot more amenable. If you pick the right bank, approach them in the right way, and deposit funds, then some form of a line of credit is possible. Credit cards are among the most expensive forms of lending, so banks are more eager to offer these than, for example, overdraft facilities.

5. Construct an Accounting System for Your Laser Cutting Business

An accounting system for your laser cutting business will help you manage your finances. You’ll need to pay wages, rent, bank costs, payroll and operational taxes, bills, material costs, and facility utilities (electricity, legal, water, and trash). You’ll also need an accounts system that allows you to: issue invoices, track payments and costs, project cash flow, and manage tax declarations and finance reports.

Bookkeeping services can do a lot of this management of basic operational factors. An in-house bookkeeper is a useful luxury when they have wider skills—but you can delay that expense.

6. Obtain the Required Licenses & Permits for Your Laser Cutting Business

Regulatory requirements vary considerably between jurisdictions. Make sure you have ascertained the certifications, licenses, inspections, and permits that will be needed in your region or state. City authorities may also have additional standards that must be met, including safety standards on: equipment, electrical, fire, health, and import and export. Missing regulatory and license details can have small and large consequences, so it is an area in which professional support and caution are advisable.

7. Obtain Business Insurance for Laser Cutting

No business can ever afford to operate without basic insurance for fire and theft, but there are layers of insurance that may be useful to consider. Often these can be integrated into a ladder of cover to be activated as the need arises, including: loss of revenue, a key person(s) injury and death of employees (with and without company fault), and exceptional weather, or earthquake.

8. Establish Your Laser Cutting Company's Brand

Brand development is an art that requires a delicate touch. Using professionals to build the basic aspects is wise, as enthusiasm is not a substitute for core skills. For full impact, you’ll need (at a minimum): a domain name, a web presence, a logo, an official business email, and social media accounts.

9. Make a Website for Your Laser Cutting Business

In today’s business, a website is necessary to connect with your target market. To build a website, you’ll need to consider: making it user-friendly and responsive. It should have alternative language versions, quoting and file-transfer capabilities, order processing, payment portals, job progress, and delivery tracking.

10. Install the Business Phone System

Phone calls are a diminishing aspect of client connectivity in most businesses. But when your client has a problem, they’re likely to pick up the phone. Knowing that calls get through and get answered is how you secure client relationships in a crisis. And it’s your handling of issues and complaints that can set you aside from most suppliers in the space. A reliable phone system is a powerful tool when personal and live contact is the right solution. This should include a no-wait call-back booking that works!

How To Find the Most Quality Location for Starting a Laser Cutting Business?

Finding the ideal location for starting a laser cutting business depends on many factors, including: the quality of buildings, fire resilience, transport availability, staff accessibility, and location security.

How To Market a Laser Cutting Business?

Marketing your laser cutting business requires a strategic approach to connecting with the target audience and showcasing your services effectively. Listed below are some of the suggested marketing steps:

- Clearly define your target audience and tailor your marketing messages to reach the right market sector.

- Develop your brand identity through logo, website, and marketing collateral. This helps establish credibility and differentiate your business from competitors.

- Showcase your work on your website and social media channels. Use high-quality images and videos to highlight the precision and quality of your cutting services.

- Leverage social media such as: Instagram, Facebook, TikTok, and LinkedIn to reach potential customers. Use them for regular updates about new work, industry news, and promotions/discounts.

- Use trade shows and events to showcase your services. Network with potential customers, and learn about new industry trends.

- Make sure your customer service is the best it can be: from the inquiry to delivery. Seek reviews and use them (carefully) on your website/social media channels.

What Are the Biggest Obstacles to Opening a Laser Cutting Industry?

A laser cutting business will bring challenges, including:

- Large Capital Investment: You’ll need a considerable range of equipment and very skilled people—right from the start.

- High Personnel Costs: You’ll need skilled people that you will continuously develop and reward.

- Compliance: Regulatory, health and safety, and financial compliance will require investment and monitoring, to stay up to date.

- Competition: The laser cutting sector is increasingly competitive. You will need differentiation strategies that set you above the market norm.

- Building and Maintaining a Client Base: Retaining and building on existing relationships will make a big difference, as will leveraging sector experience.

- Equipment Maintenance: Expensive equipment must be kept at peak performance at all times. Preventative maintenance programs, careful condition monitoring, and outage preparedness are significant tasks that cannot be neglected.

- Workflow: Managing workflow to deliver high-quality products on time and within budget is not a small task. It must be handled with thoroughness, to ensure service standards at all stages.

What Are the Key Cost Elements for the Laser Cutting Industry?

The key cost elements for a laser cutting business are:

- Premises

- Equipment

- Personnel

- Materials

- Shipping

- Operational Overheads (maintenance, power, legal services, accounting, cost of capital, etc.)

- Marketing and Advertising

Why Is Laser Cutting a Great Possibility for Business?

Laser cutting has replaced a range of slower, more costly processes. It has grown the total market for material processing services. Laser cutting is a high-growth sector and is likely to remain so. The range of sectors served by laser cutting services is also expanding, as the technology and the market appreciation of the capabilities grow. On balance, sector growth is likely to continue for the foreseeable future, making a well-run laser cutting business a strong financial prospect.

How Can a Laser Cutting Business Generate Revenue?

A laser cutting business can generate revenue by finding, serving, and retaining customers to buy the services and products.

How Can a Laser Cutting Business Sustain Itself?

A laser cutting business can sustain itself by:

- Acquiring and retaining clients.

- Providing great services.

- Building a strong team.

- Staying ahead of the tech curve.

- Growing the market breadth and depth.

- Diversify carefully.

How Do You Price Laser Cutting?

Pricing your laser cutting service or product depends on many factors. These include:

- Basic Material Consumption: There will be a basic material consumption for any task, which must also include wastage and total cost of purchase.

- Operational Cost Elements: These should roll labor, premises, and other costs into a relatively simple formula that results in a measure of cost-per-hour for tasks, multiplied by a realistic assessment of the time required for each part or project.

- Shipping Costs: Will vary with weight, distance, and any client requirements that may add cost, including insurance and special packaging.

With all of these actual costs totaled you should get to a total cost of service. The amount is then multiplied by the margin of your business plan and revenue projections. This multiplier is where your competitive flexibility lies, once you have tight control of costs.

What Equipment Does a New Laser Cutting Business Owner Need To Invest in?

The basic equipment that a new laser cutting business owner needs is:

- Laser cutters.

- Lifting gear for large stock.

- Maintenance equipment.

- A well-equipped workshop for various tasks.

- Racking.

- Shop-floor transport (may be integrated with lifting gear).

- Gas bottle handling equipment and safe storage, both central and by each machine.

- Safety barriers and screens.

What Is the Best Type of Laser to Start a Business?

The best type of laser to start a business depends on a variety of factors. There is a wide spectrum of equipment choices for laser cutters. Select machinery according to: budget, expected throughput, material types, stock thicknesses, and operator experience. Some examples are listed below:

- A cutter farm may use an array of small and medium machines to deliver small and light parts to private/home/hobby clients.

- A cutter specializing in paper/card/wood and other natural materials will generally need relatively lightweight equipment.

- Specializing in reflective materials such as aluminum and copper suggests choosing a YAG-equipped laser cutter.

- For lower CAPEX setups, where operational costs can be tolerated, CO2 lasers offer a good general capability. Their maintenance and power costs are high and the lasers themselves have a relatively short life.

- For higher CAPEX setups, fiber laser cutters offer much lower operational costs and longer life. They have in the past been power limited, but the differential to CO2 laser power is diminishing fast.

Machine bed sizes are highly variable. It is wise to select large machines if your expected market includes heavy industries, aerospace, and architectural materials.

What Are the Requirements for Starting a Laser Cutting Business?

The requirements to establish a laser cutting business are:

- Company Registration

- Capital

- Tax Registration

- Complete Local and National Compliance Requirements

- Premises

- Equipment

- Skilled Personnel

- Customer Base

Is a Laser Cutting Business Profitable?

Yes, a well-run, well-equipped laser cutting business has very high-profit potential. Staying at the technical leading edge and aggressively marketing is necessary to maintain a leading position.

What Are the Advantages and Disadvantages of a Laser Cutting Business?

The advantages of a laser cutting business are:

- High profitability is possible, with the right customers, tech, and team.

- Attracting capable staff can be relatively easy, because of the advanced technology and interesting work involved—as long as the rewards are high.

- Increasing the range of associated services can easily deepen client relationships and broaden market access.

- Connection to a high-tech client base can often lead to interesting opportunities for diversification.

The disadvantages are:

- Complex manufacturing business.

- Technology moves fast, so today's leading edge is tomorrow's norm.

- People in this space have highly portable skills, so stabilizing a team is not easy.

- CAPEX needs are high and will remain high to stay relevant and busy.

- Working capital needs are high, as fast turnaround requires materials in stock.

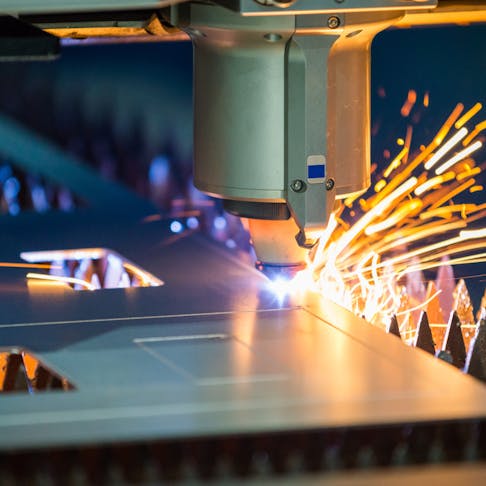

What Is Laser Cutting?

Laser cutting uses a CNC transport mechanism to move a laser or laser optics delivery system in a 2D, 2.5D, or 3D path to cut and etch generally flat material for net shape extraction. The cutting process uses laser energy to vaporize/melt the target material. It often uses a gas stream (or air) to blow out the detritus from the cut and ensure the optical path remains clear. Oxygen assistance can also be used, to accelerate the laser cutting process by oxidation, in some materials.

What Is the Best Laser Cutter for Small Businesses?

The best laser cutter for small business:

- xTool M1

- Glowforge® Plus

- Orion Motor Tech

- Zing 24

- xTool D1 Pro

For more information, see our guide on the Best Laser Cutter for Small Businesses.

Summary

This article presented starting a laser cutting business, explained how, and discussed the various steps and importance of each one. To learn more about laser cutting businesses, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including sheet cutting and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Copyright and Trademark Notices

- GLOWFORGE® is a trademark of Glowforge Inc.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.