Laser welding is a high-precision technique to join metal components using a concentrated beam of light. Known for its speed, accuracy, and minimal distortion, this advanced process is widely used in industries such as automotive, aerospace, electronics, and medical device manufacturing. The method relies on a computer-controlled system that continuously monitors and adjusts parameters to ensure consistency and quality throughout the weld. Depending on the application, different welding techniques—such as conduction welding or deep penetration welding—may be employed to meet specific requirements.

While laser welding offers many advantages, including reduced heat-affected zones and the ability to weld complex geometries, it also presents some challenges, such as high equipment costs and the need for precise joint alignment.

In this article, we will describe laser welding, how it works, and the five key steps of the laser welding process and explore how each one contributes to creating strong, reliable welds.

What Is Laser Welding?

Laser welding is a precise and efficient technique that uses a high-energy laser beam to join materials—typically metals or thermoplastics—by creating a strong, durable bond. This method offers several key advantages, including high precision, a minimal heat-affected zone, and the ability to weld complex or delicate geometries. Laser welding is widely used across various industries such as automotive, aerospace, electronics, and medical devices due to its speed, accuracy, and adaptability.

For a more detailed overview, see our comprehensive guide on What Is Laser Welding?

How Does Laser Welding Work?

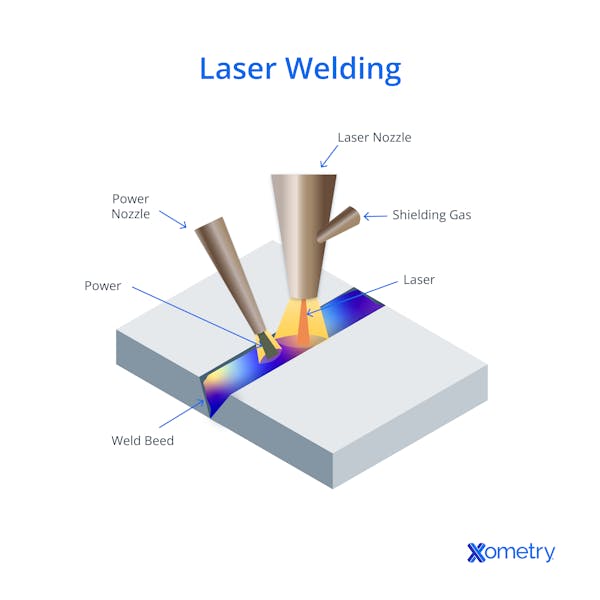

Laser welding is a precision joining process that uses a highly focused, high-energy-density laser beam to heat and melt materials at the weld joint. When the beam is concentrated on a specific area, the localized energy input raises the temperature of the base materials to their melting point. The resulting molten pool solidifies rapidly along the beam path, forming a strong metallurgical bond.

An automated control system manages critical welding parameters such as laser power, travel speed, focal position, and shielding gas flow, ensuring consistent and precise weld quality. Due to the laser’s narrow and concentrated heat source, laser welding enables high-speed processing with minimal thermal distortion and a small heat-affected zone (HAZ). This makes it particularly suitable for applications requiring fine welds, deep penetration, or joining dissimilar materials.

Five Steps of the Laser Welding Process

1. Preparation

The first step in laser welding is preparation. This includes cleaning the workpieces to remove contaminants, ensuring the fit-up and alignment are correct, planning the joint configuration, and utilizing fixtures commonly made from a solid milling block. This step is essential to guarantee high-quality welds. Cleaning removes substances that could interfere with welding, and fit-up and alignment ensure precise and durable welds. Joint construction enables effective heat transfer and the desired strength. It might be necessary to use fixtures to hold the parts in place while welding.

2. Beam Focusing

Beam focusing, a crucial phase in laser welding, involves expanding and reshaping the laser beam to concentrate its energy on the weld joint. It includes collimation and focusing to converge the beam into a smaller spot size. The laser beam's effectiveness for welding is only realized when it undergoes the process of focusing through a specialized lens. Proper beam focusing is essential, as it determines the intensity and size of the energy spot, which in turn impacts the weld quality, depth, and width. It enables precise heating and melting of the workpieces, enhancing weld quality and control. Key considerations for optimal energy delivery include lens selection, optimizing focal distance, and aligning the beam with the weld joint. For more information, see our guide on Laser Beam Quality.

3. Welding Parameters

Welding parameters in laser welding are the specific settings that control the laser power, welding speed, beam diameter, pulse duration, and repetition rate. Laser power determines the energy delivered to the weld joint, while welding speed affects heat input and the size of the heat-affected zone. Beam diameter determines the energy concentration, while pulsing duration and repetition rate control the melting and solidification processes. Proper selection and optimization of welding parameters are crucial for achieving desired weld characteristics such as strength and quality. Factors such as material type, thickness, joint design, and application requirements should be considered when determining welding parameters. It is recommended to follow the welding parameters of the machine’s manufacturer and the suggested settings for the material.

4. Welding Process

The actual welding process involves directing the laser beam along the joint to melt and fuse the materials. A coherent energy source emits a high-energy beam. The beam passes through a delivery path of mirrors to a series of lenses and focuses on a specified spot on the workpiece. As the beam hits the workpiece, localized heating and rapid melting occur in the joint area. Proper execution of this step is essential for achieving strong and reliable welds with minimal distortion. The welding process ensures high-quality bonds between materials.

5. Cooling and Solidification

After the application of heat, the molten metal begins to cool down. The cooling rate affects the weld's microstructure and mechanical properties. As the metal cools, it solidifies, forming a strong bond between the workpieces. Proper cooling and solidification are essential for achieving desired weld characteristics and minimizing residual stresses. Techniques such as post-weld heat treatment or cooling devices can control the cooling rate and optimize the weld's properties. Ensuring controlled cooling and solidification enhances the overall integrity and strength of the weld.

What Are the Types of Laser Beam Welding?

There are two main categories of laser beam welding: heat conduction welding and deep penetration (or keyhole) welding.

To explore further, refer to our guide: Types of Laser Welding.

1. Heat Conduction Welding

In this method, the laser beam generates heat at the surface of the material, causing it to melt. The heat then conducts through the material, resulting in the fusion of the workpieces. Heat conduction welding is suitable for thinner materials and applications in which a shallow weld depth is desired.

2. Deep Penetration/Keyhole Welding

This method involves greatly increasing the laser beam's intensity to penetrate the material deeply or to form a keyhole. The material is vaporized by the intense beam, creating a cavity filled with vapor. Then, the keyhole's walls collapse, completely fusing the two workpieces. Deep penetration welding is commonly used for thicker materials and applications that call for stronger welds.

What Is the Importance of Laser Welding?

Laser welding is important because it can produce welds with a high aspect ratio, or a large depth to a narrow width. This capability makes laser welding suitable for joint configurations that might not be possible with other conduction-limited welding techniques. For instance, stake welding through lap joints is a challenge with conventional methods, but is possible with laser welding. With flexibility and versatility across numerous industries, this capability increases the number of applications in which precise and powerful welds are necessary.

What Are the Advantages of Laser Welding Compared to Conventional Welding?

Advantages of laser welding compared to conventional welding techniques include:

- Laser welding delivers exceptional accuracy, producing clean and narrow welds with minimal deviation.

- The focused laser beam reduces thermal distortion and helps preserve the mechanical and structural properties of the base material.

- Capable of welding a wide range of materials—including dissimilar metals—laser welding expands the scope of design and manufacturing possibilities.

- The process allows for rapid welding, significantly improving productivity and reducing cycle times.

- Laser beams can be directed with great precision, making it possible to weld in hard-to-reach or confined areas.

- Laser welding produces low-spatter, high-quality joints, often eliminating the need for extensive cleanup, grinding, or machining afterward.

What Are the Disadvantages of Laser Welding Compared to Conventional Welding?

Disadvantages of laser welding compared to conventional welding techniques include:

- Laser welding systems are typically more expensive to purchase and maintain than conventional welding equipment.

- Some conventional techniques can achieve greater weld depth in a single pass, making them more suitable for very thick materials.

- Operating and optimizing a laser welding system demands technical expertise and proper training.

- Laser welding can be more sensitive to certain material properties, such as high reflectivity or inconsistent thickness, which may affect weld quality.

For more information, see our full guide on the Disadvantages of Laser Welding.

How Much Does a Laser Welding Machine Cost?

The cost of a laser welding machine can vary significantly based on factors such as laser type, power output, brand, build quality, and system configuration. Entry-level benchtop or handheld fiber laser welders typically range from $5,000 to $10,000. However, industrial-grade systems equipped with high-power lasers, advanced cooling systems, CNC or robotic integration, and real-time monitoring features can cost $20,000 to over $100,000, depending on the complexity and customization required.

Key cost drivers include:

- Laser Power: Higher wattage (e.g., 1000W–6000W) increases cost but enables deeper penetration and faster welding.

- Welding Area and Work Envelope: Larger or more adaptable work areas may require gantry systems or multi-axis robotic setups.

- Degree of Automation: Systems with automated feeders, vision systems, or integrated quality assurance tools command higher prices.

- Application-Specific Features: Requirements such as welding of reflective metals (e.g., copper, aluminum), precision micro-welding, or hermetic sealing affect system design and cost.

For an accurate quote, it is advisable to consult with laser equipment manufacturers or authorized distributors who can tailor configurations based on specific production requirements, material types, and quality standards.

Common FAQs About the Laser Welding Process

Can Laser Welding Be Used in Any Type of Welding Application?

No, laser welding may not be suitable for all types of welding applications. While laser welding offers numerous advantages, it has limitations such as limited joint thickness and sensitivity to material properties. Additionally, the cost and equipment requirements of laser welding may not be practical for certain applications. Each welding method has its strengths and limitations, and the choice depends on the specific requirements of the application. For more information, see our guide on Laser Welding Applications.

Is Laser Welding Expensive?

Yes, compared to other welding techniques, laser welding can be quite expensive. Additionally, effective use of laser welding systems often requires specialized training and knowledge. Laser welding's improved accuracy and efficiency, however, can result in cost savings in some situations by reducing material waste and speeding up production.

Is Laser Welding Efficient?

Yes, laser welding is an effective method. The laser beam's concentrated heat source enables precise and localized melting, resulting in reduced heat-affected zones and less distortion. High welding speeds are another benefit of laser welding, which makes it appropriate for automated and large-scale manufacturing processes.

Summary

This article presented the five steps of the laser welding process, explained what it them, and discussed them in detail. To learn more about laser welding, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including sheet cutting and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.