What Is Mylar?

Mylar® is a polyester film that is widely used due to its exceptional mechanical and chemical properties. It is so popular that it has become nearly synonymous with any plastic film. Mylar is used in numerous applications, from helium-filled balloons and food packaging to electrical and thermal insulators. It was first developed in the mid-1950s by the companies Imperial Chemical Industries (ICI), Hoechstand, and DuPont. It is a registered trademark of DuPont Teijin Films. This article will define Mylar film, describe how it’s made, discuss its properties, and give examples of Mylar applications.

Mylar is made from polyethylene terephthalate (PET). The material is also known by its scientific name BoPET (biaxially-oriented polyethylene terephthalate). Here's how Mylar is fabricated:

- PET polymer is melted and extruded onto a chilled drum roller to form a film.

- The film is stretched biaxially, in the machine (or feed) direction, and in the transverse (width) direction. This is achieved by feeding the film over a series of rollers and then into a stenter frame where it is stretched in the transverse direction. This stretching process serves to orient the PET molecules in such a way as to enhance the film’s mechanical properties.

- The film is heated to 200°C (392°F) to stabilize its structure and to ensure that it does not shrink at temperatures below the original heat set temperature.

At the end of the fabrication process, the Mylar film is so smooth that it tends to stick to itself. Mylar material is often coated with silicon dioxide (SiO2) to reduce stickiness. Additionally, Mylar can be coated with evaporated gold, aluminum, or other metal using a physical vapor deposition process to reduce transparency, increase reflectivity, and make it less permeable to gases.

Useful Properties of Mylar

The versatility of Mylar, and its ability to retain its properties across a wide temperature range (-94°F to 302°F or -70°C to 150°C), make it ideal for a variety of applications across different industries. Mylar can be used in extremely low and high temperatures (-418-392°F, or -250-200°C) as long as mechanical requirements are not too demanding. Extreme temperatures can cause degradation of Mylar’s tensile strength and ductility. The properties of Mylar are listed below:

- Tensile strength of 29 ksi

- Dimensionally stable over a wide temperature range

- Chemically inert, resistant to oils, solvents, moisture, and grease

- Low permeability—can be used as a barrier against most liquids and gasses

- Excellent thermal stability and a low thermal expansion coefficient of 1.7 × 10 –5 in/in/°C (9.5 × 10 –6 in/in/°F). This makes the material an excellent thermal insulator

- High electrical resistivity of 1018 ohm⋅cm, making it an excellent electrical insulator

- Reflective. If coated with metallic particles, its reflectivity contributes to thermal stability and aesthetic appeal

- If not coated, Mylar is transparent and can transmit 80-90% of radiation in visible and infrared spectrums. This can be desired for certain applications such as tags, and equipment labels

Uses of Mylar

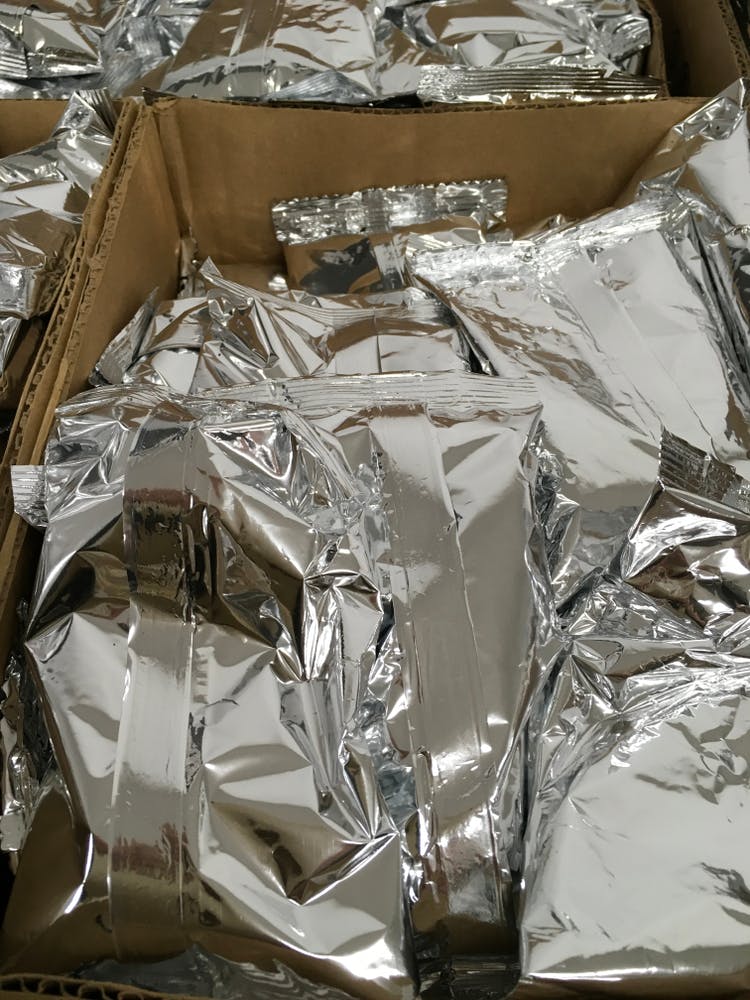

Mylar overall is a great material. Its strength and dimensional stability over a wide temperature range make it a versatile material. Its low permeability makes it great for food packaging, while its electrical properties make it a great electrical insulator. Figure 1 below is an example of a Mylar packaging containers:

Mylar packaging containers.

Image Credit: Shutterstock.com/MicheleMidnight

Some common uses of Mylar are in:

- Flexible food packaging, such as: yogurt lids, potato chip bags, foil coffee pouches, and candy wrappers

- Product packaging for clothing, books, and other consumer products

- Product labels, stickers, and tags

- Thermal insulation for air ducts, tents, survival blankets, and other temperature-sensitive items

- Electrical insulation for wiring applications

- Decorative balloons, party decor, kites, and other items

For more information, see our guide on Laser Cutting.

Uses of Laser Cut Mylar

Mylar is often processed by laser cutting because it is easy to cut and can be cut by even entry-level laser cutters. Its low vaporization temperature makes laser cutting the perfect option for processing Mylar products into the desired shape. The primary application of laser-cut Mylar is the fabrication of stencils for craft applications. However, laser-cut Mylar can also be used to create beautifully intricate patterns, shapes, and designs, or to create consumer products such as food packaging and others listed abo ve. All available Mylar thicknesses are well within the capabilities of standard laser cutters. Its low thickness, coupled with its relatively low vaporization temperatures (662°F or 350°C) when compared to other plastics like Delrin®, make laser cutting Mylar easy and efficient.

Mylar is often used to produce stencils for craft and hobby applications. Laser cutting is a popular method to fabricate stencils because the laser produces accurate, clean cuts. While other materials, like cardboard and cardstock, can also be laser cut to produce stencils, they are not ideal to provide clean artwork. Additionally, these materials lack longevity and can easily be deformed.

How To Use Mylar for Making Stencils

To laser cut Mylar stencils, use low power and high cutting speed. This helps prevent the cut edges of the sheet from melting and vaporizing. The steps below describe in detail how to use Mylar for making stencils by laser cutting:

- Place a backer board, such as cardboard or cardstock, underneath the Mylar sheet. This will protect the laser work table or the surface directly underneath the laser from being damaged by the laser.

- Secure the sheet to the backer board using a glue stick, spray adhesive, or tape. Then, secure the backer board to the work table using tape or a clamp. This will prevent the sheet from shifting during laser cutting. It will also allow the finished stencil to be easily removed since the unwanted portions will stick to the backer board.

- Configure the laser system for cutting Mylar material. Cutting speeds should be sufficiently fast to avoid the material from melting excessively. However, the thickness of the sheet determines the power that must be used.

Table 1 below shows the recommended power settings and speeds for cutting various thicknesses of Mylar:

| Sheet Thickness | Laser Power | Cutting Speed |

|---|---|---|

Sheet Thickness 0.1 | Laser Power 7 W | Cutting Speed 150 mm/s |

Sheet Thickness 0.20 mm | Laser Power 8 W | Cutting Speed 150 mm/s |

Sheet Thickness 0.25 mm | Laser Power 9 W | Cutting Speed 150 mm/s |

Sheet Thickness 0.25 mm | Laser Power 9 W | Cutting Speed 150 mm/s |

Xometry provides a wide range of manufacturing capabilities including CNC machining, 3D printing, injection molding, laser cutting (including laser cutting of Mylar!), and sheet metal fabrication. Get your instant quote today.

Copyright and Trademark Notices

- Mylar® and Melinex® are trademarks of DuPont Teijin Films.

- Hostaphan® is a trademark of Mitsubishi Chemical Group.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.