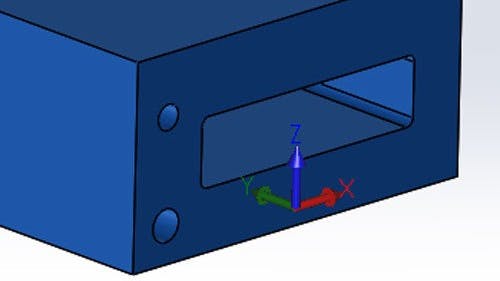

1. The "Work Envelope" of a machining center...

...describes the machine's travel dimensions. Xometry's partner network includes CNC machiningcenters with 64" (X)" by 32" (Y) by 38" (Z) travel limitations. Keep in mind that the travel limitations do not necessarily translate to maximum part dimensions. Deep features requiring long tooling can cut into the effective work envelope of a machine.

CNC work envelope dimensions

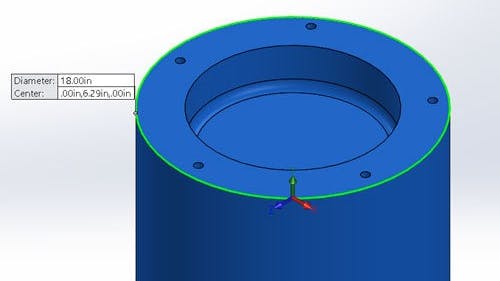

For parts manufactured on a lathe, the critical limiting dimensions are...

...the maximum part diameter and the overall length of the part. Xometry supports parts up to 18" in diameter, but special considerations can be made for larger parts. The maximum overall length of parts that can be supported also depends on the part's maximum diameter. Live tooling lathes can manufacture more complex turned parts with off-axis features, but this often means smaller effective work envelopes.

A CNC Lathe part

CNC Anodized Parts

Congratulations! You're now on your way to building parts that are optimized for our partner network's machine sizes. Read more design tips from our CNC Design Guide or quote now.