ABS 3D Printing Service

Get instant online quotes on 3D Printed ABS parts. Free shipping on all US orders. ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified.

About 3D Printing ABS

ABS (acrylonitrile butadiene styrene) is one of the strongest standard plastics used in FDM 3D printing and has well-balanced mechanical properties, such as high strength and good resilience, and impact resistance, making it a popular material for a range of industries for both prototyping and end-use. Xometry 3D prints true ABS through the Fused Deposition Modeling (FDM) process. We offer a wide range of ABS, from cost-effective general-purpose options to carbon fiber reinforced options.

It is worth noting that FDM parts are anisotropic, meaning that their material strength varies depending on the direction in which the part is fabricated.

3D Printing with ABS at a Glance

| Applications | Advantages | Disadvantages | Minimum Lead Time * | Comparative Cost | Max Part Size * |

|---|---|---|---|---|---|

Applications

| Advantages

| Disadvantages

| Minimum Lead Time * 1 Day | Comparative Cost $$ (Medium) | Max Part Size * 24” x 36” x 36” (610 mm x 915 mm x 915 mm) |

* Applies to US-based production only.

General Purpose ABS (FDM)

A low-cost grade of ABS for general-purpose use, typically produced via Fused Filament Fabrication (FFF) using an array of 3D printers. International production is available for this material, providing reduced pricing compared to our other ABS materials. Please note that the exact material and its properties and colors may vary slightly due to a broader allowance on the material and printing platform.

| Available Colors | Tensile Strength, Yield (XZ MPa-ZX MPa) | Elongation at Break (%) | Heat Deflection Temperature (℃) @ 66 psi |

|---|---|---|---|

Available Colors Black, Blue, Dark Grey, Ivory, Red, White | Tensile Strength, Yield (XZ MPa-ZX MPa) 33-28 | Elongation at Break (%) 10.5-4.7 | Heat Deflection Temperature (℃) @ 66 psi 87 |

Data is based on generic ABS filament for FFF printers and is for reference only. See our FDM page for complete data sheets.

Stratasys ABS-M30 (FDM)

For higher consistency and stricter quality control requirements compared to our general-purpose option, this ABS material from Stratasys is run using only OEM Fortus equipment. This formulation of ABS has a higher HDT and is stronger than standard ABS filament, offering better interlayer bond strength and increased strength in the Z-axis. Applications can include tool fixtures and low-volume production parts.

| Available Colors | Tensile Strength, Yield (XZ MPa-ZX MPa) | Elongation at Break (XZ%-ZX%) | Heat Deflection Temperature (℃) @ 66 psi |

|---|---|---|---|

Available Colors Black, Blue, Dark Grey, Ivory, Red, White | Tensile Strength, Yield (XZ MPa-ZX MPa) 30.8-27.5 | Elongation at Break (XZ%-ZX%) 8.1-1.8 | Heat Deflection Temperature (℃) @ 66 psi 104.4 |

Properties achieved by running OEM materials and parameters on OEM Fortus equipment. See our FDM page for complete data sheets.

Stratasys ABS-ESD7 (FDM)

This grade of Stratasys ABS is electrostatic-dissipative, meaning it possesses special anti-static properties. This is possible due to the inclusion of extra carbon filler in the formulation. This has the strength benefits of ABS while also allowing it to be used alongside sensitive electronics without the risk of static discharges damaging delicate components. This makes it ideal for electronic housings and fixtures for electronic components.

| Available Colors | Tensile Strength, Yield (XZ MPa-ZX MPa) | Elongation at Break (XZ%-ZX%) | Heat Deflection Temperature (℃) @ 66 psi | Surface Resistance |

|---|---|---|---|---|

Available Colors Black | Tensile Strength, Yield (XZ MPa-ZX MPa) 35.4 | Elongation at Break (XZ%-ZX%) 3.4-1.59 | Heat Deflection Temperature (℃) @ 66 psi 104.6 | Surface Resistance 10^6 Ω - 10^9 Ω |

Properties achieved by running OEM materials and parameters on OEM Fortus equipment. See our FDM page for complete data sheets.

ABS-M30i (FDM)

This grade of Stratasys ABS is specially formulated to be biocompatible in accordance with ISO 10993 USP Class VI. It can also be gamma- or Eto-sterilized. It is essential to recognize that, although the material is certified as biocompatible, this does not guarantee that the end product will be automatically compliant. This material can be used to make functional prototypes, food packaging, or end-use components.

| Available Colors | Tensile Strength, Yield (XZ MPa-ZX MPa) | Elongation at Break (XZ%-ZX%) | Heat Deflection Temperature (℃) @ 66 psi |

|---|---|---|---|

Available Colors Ivory | Tensile Strength, Yield (XZ MPa-ZX MPa) 36 | Elongation at Break (XZ%-ZX%) 4 | Heat Deflection Temperature (℃) @ 66 psi 96 |

Properties achieved by running OEM materials and parameters on OEM Fortus equipment. See our FDM page for complete data sheets.

ABS-CF10 (FDM)

This material from Stratasys combines standard ABS material with 10% chopped carbon fiber by weight, resulting in a 50% stiffer and 15% stronger ABS than the standard option. It's a great choice where increased stiffness and weight reduction are desired. Applications include jigs, fixtures, end effectors, and manufacturing tools. In addition to reinforcing the material, the fiber chop also yields a matte finish and slightly more uniform layer stacking.

| Available Colors | Tensile Strength, Yield (XZ MPa-ZX MPa) | Elongation at Break (XZ%-ZX%) | Heat Deflection Temperature (℃) @ 66 psi |

|---|---|---|---|

Available Colors Black | Tensile Strength, Yield (XZ MPa-ZX MPa) 39.4-19.6 | Elongation at Break (XZ%-ZX%) 1.6-1.1 | Heat Deflection Temperature (℃) @ 66 psi 100 |

Properties achieved by running OEM materials and parameters on OEM Fortus equipment. See our FDM page for complete data sheets.

Cost-saving Tips

To save money with ABS printing, follow these cost-saving design tips:

DFM: ABS 3D printing with FDM technology requires special considerations when designing parts. FDM machines construct parts from the bottom up, so large overhangs will require support. Large internal cavities are not ideal, as they make support structures difficult to remove, thereby increasing post-processing time. Additionally, care must be taken when designing load-bearing components, as FDM parts are generally weakest in the Z-axis due to the limited bond strength between layers.

Choose the right ABS: The above-listed ABS materials are each designed for specific use cases and should only be used when required. For example, biocompatible ABS is not needed for a tooling fixture and would increase the overall cost of the part for no reason.

Finishes

ABS plastic printing using FDM technology does not typically have a wide range of possible surface finishes. There is, however, a wide range of colors available for standard ABS.

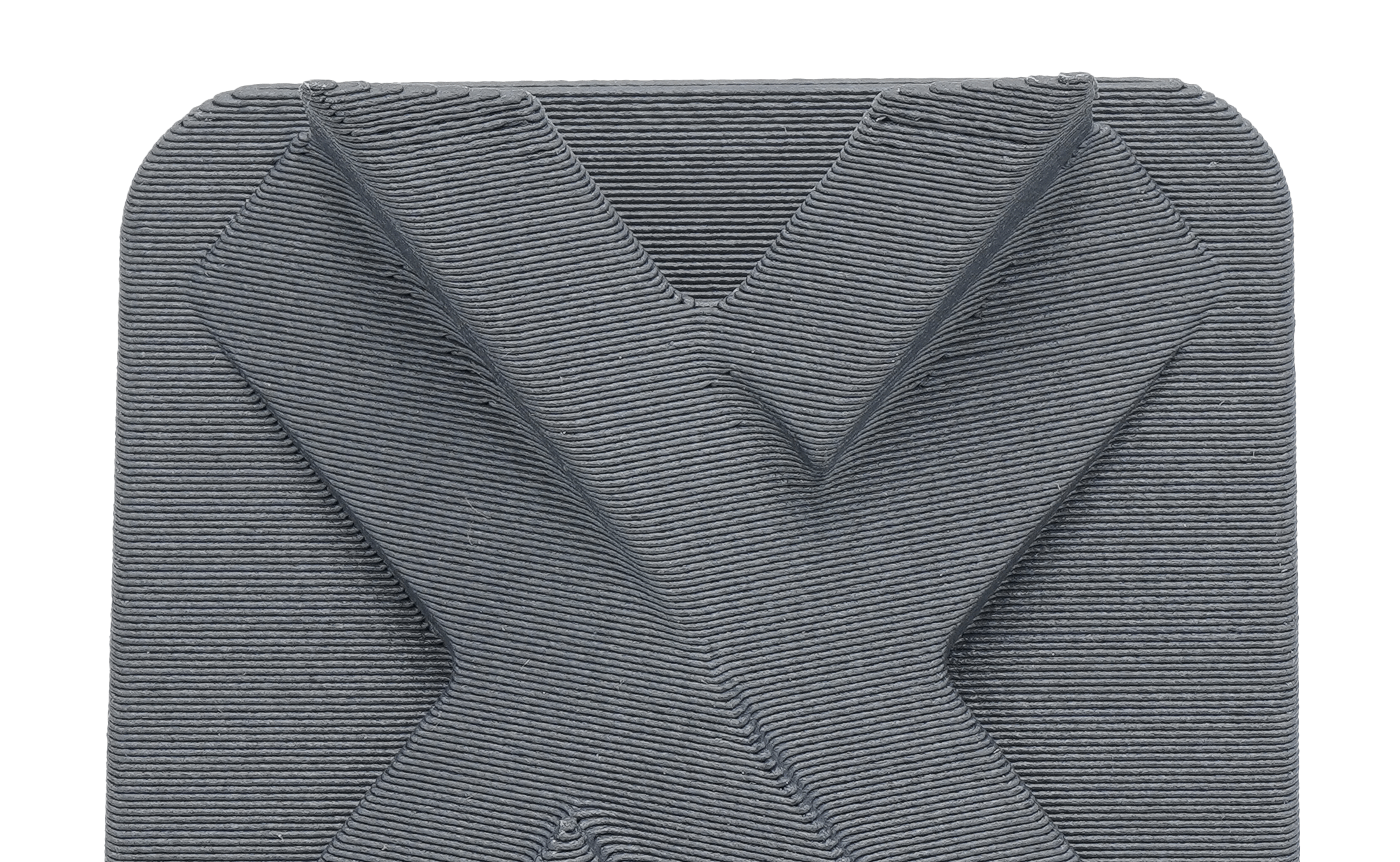

Standard: Support structures are removed, and some light sanding may be performed at the support locations. FDM parts typically exhibit clear layer lines, known as stepping. If a smooth surface finish is required right off the machine, then other 3D printing technologies should be considered.

Other: Custom surface finishes, like painting and additional sanding, can be requested.

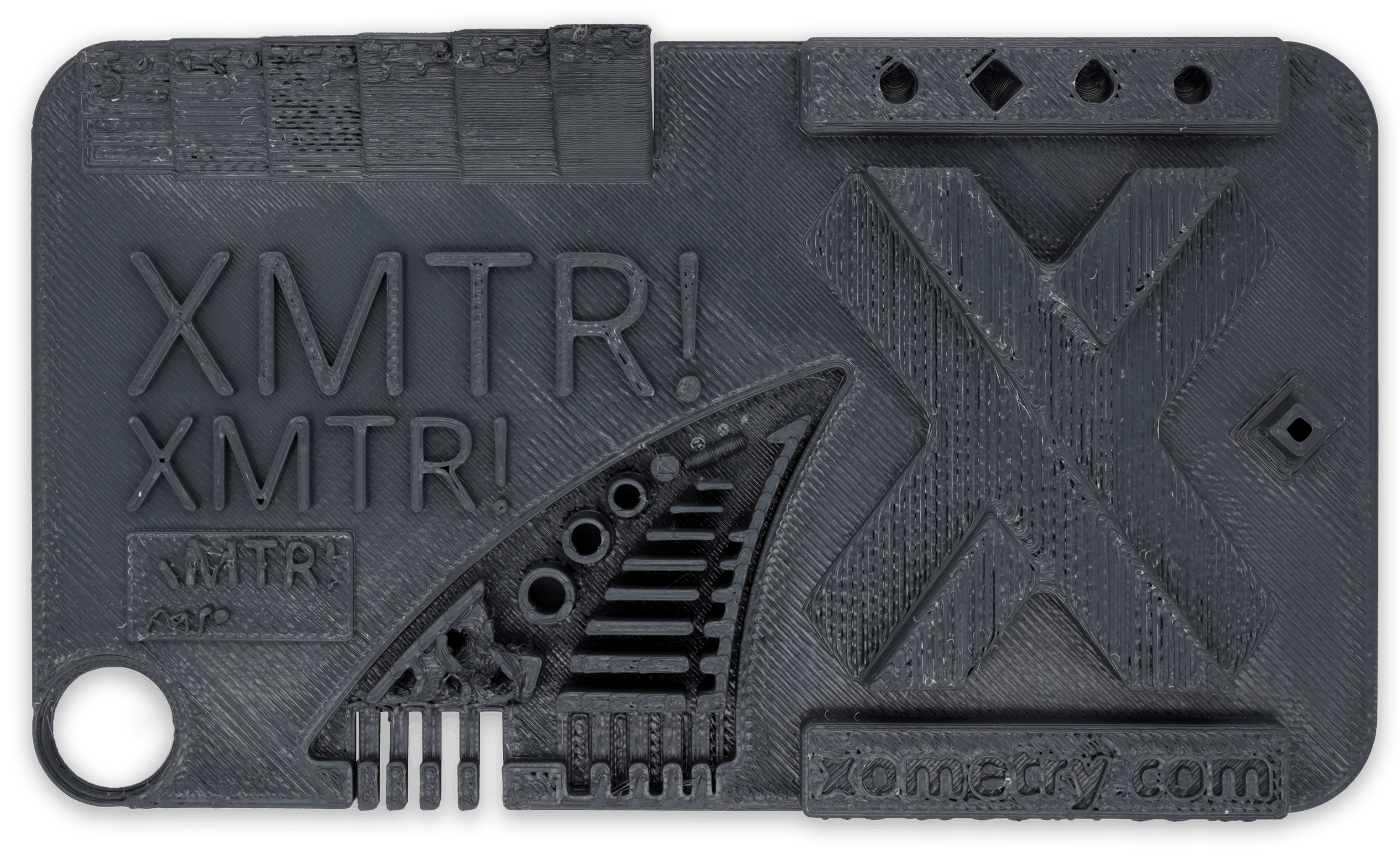

ABS-M30 in various colors.

Need Parts 3D Printed in ABS?

Get instant pricing and lead times on custom ABS parts today!