PAEK & PEKK 3D Printing Service

Get instant online quotes on 3D Printed PAEK and PEKK parts. Free shipping on all US orders. Xometry is ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified.

What's the Difference Between PAEK, PEKK, and PEEK?

PAEK, PEKK, PEEK; they sound incredibly similar and can be confusing, but let's break it down. PAEK stands for PolyArylEtherKetone, and it is the overarching family name for these high-performance "super polymer" plastics. Every material in this group, including PEKK and PEEK, shares unmatched durability, extreme heat resistance, and superior chemical stability. If your application involves harsh environments or high temperatures, a PAEK-based material may be the solution.

PEEK and PEKK are simply two distinct and common members of the PAEK family. The difference between them is subtle, stemming from a minor variation in their internal chemical structure. In practical terms, they both deliver top-tier performance, but these small internal differences allow manufacturers to fine-tune properties for 3D printing. For instance, PEEK-based materials, such as VICTREX AM 200, are specially formulated to enhance interlayer bonding, while PEKK-based materials, like Antero 800NA, are tuned for better dimensional stability and reduced warping, resulting in an easier and more reliable printing experience compared to standard PEEK.

3D Printing with PAEK Materials at a Glance

| Applications | Advantages | Disadvantages | Minimum Lead Time | Comparative Cost | Max Part Size |

|---|---|---|---|---|---|

Applications

| Advantages

| Disadvantages

| Minimum Lead Time 4 Days | Comparative Cost $$$$ (Very High) | Max Part Size 24” x 36” x 36” (610 mm x 915 mm x 915 mm) |

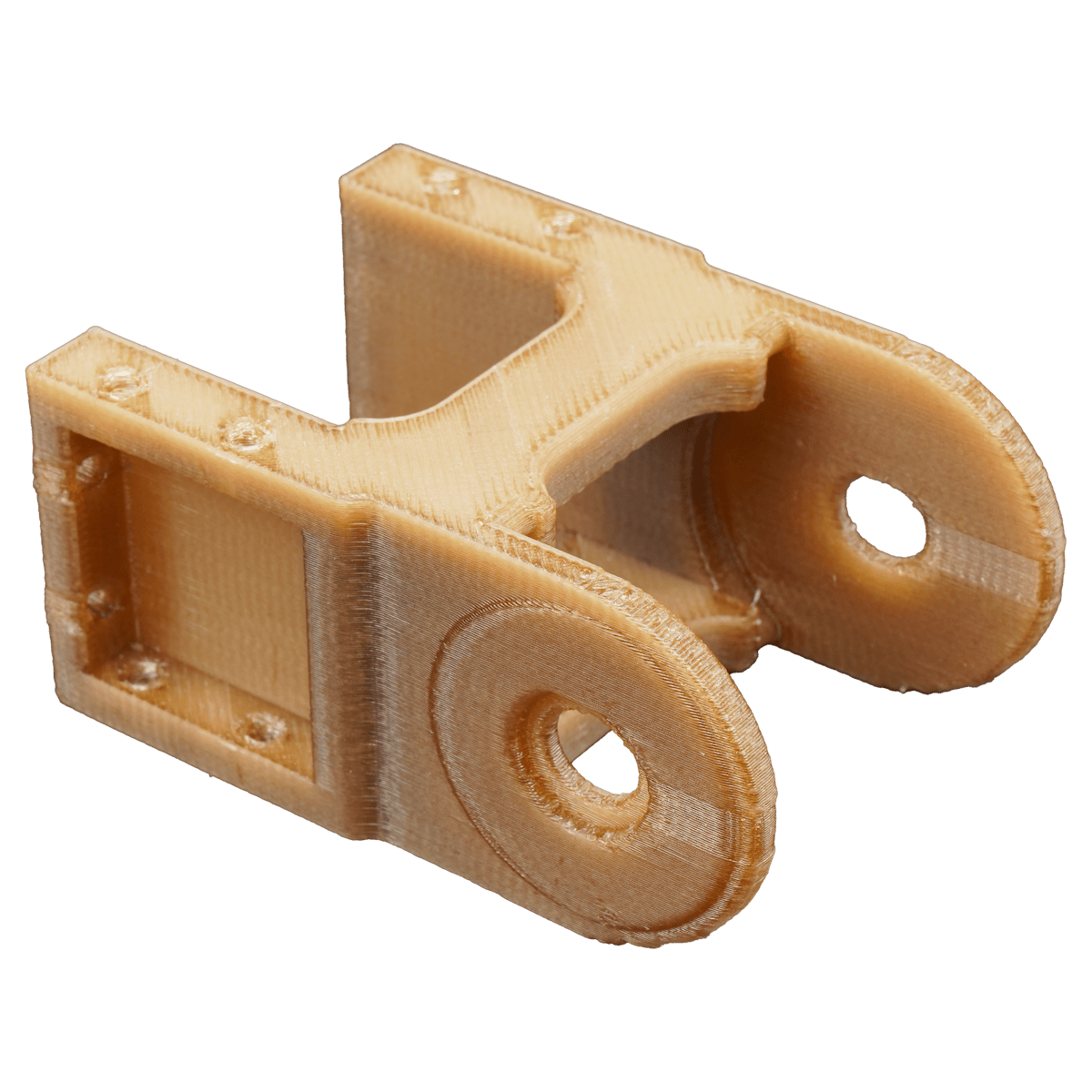

VICTREX AM™ 200 (FDM)

VICTREX AM™ 200 is a specialized grade of PAEK, formulated as a unique Low-Melt PEEK (LMPAEK) polymer explicitly optimized for 3D printing. This material has enhanced melt flow and fusion characteristics, resulting in significantly stronger interlayer bonding between printed layers. This means that the printed parts retain the high strength, superior chemical resistance, and extreme thermal stability of traditional PEEK, while having a lower risk of build failure and being easier to process. This makes it an ideal material for demanding, high-performance components, such as structural aerospace components, medical devices, and high-temperature industrial fixtures.

| Available Colors | Tensile Strength, Yield (XZ MPa-ZX MPa) | Elongation at Break (%) | Glass Transition (Tg) - Onset |

|---|---|---|---|

Available Colors Amber | Tensile Strength, Yield (XZ MPa-ZX MPa) 60.7-48.9* | Elongation at Break (%) 8.3-3* | Glass Transition (Tg) - Onset 151 |

Properties achieved by running OEM materials and parameters on OEM Fortus equipment. See our FDM page for complete data sheets.

* Values based on F900 w/SUP8000B Support configuration.

Antero 800NA (FDM)

Antero 800NA is a high-performance PEKK-based thermoplastic renowned for its exceptional chemical and mechanical properties, making it an excellent choice for demanding engineering applications. Its formulation is engineered to provide superior chemical resistance, ultra-low outgassing, and excellent wear properties compared to many other polymers. This material is widely trusted in industries such as aerospace and high-end industrial sectors, where components must maintain their integrity when exposed to harsh environments, including corrosive chemicals, fuels, and the vacuum of space. Antero 800NA excels at retaining its structural integrity and dimensional stability across wide temperature swings, making it an ideal option for components such as ventilation manifolds, pump impellers, and high-heat jigs.

| Available Colors | Tensile Strength, Yield (XZ MPa-ZX MPa) | Elongation at Break (XZ%-ZX%) | Heat Deflection Temperature (℃) @ 66 psi |

|---|---|---|---|

Available Colors Amber | Tensile Strength, Yield (XZ MPa-ZX MPa) 86.7-59.4 | Elongation at Break (XZ%-ZX%) 6.1-2.3 | Heat Deflection Temperature (℃) @ 66 psi 158 |

Properties achieved by running OEM materials and parameters on OEM Fortus equipment. See our FDM page for complete data sheets.

Antero 840CN03 (FDM)

While Antero 800NA offers superior mechanical strength and chemical resistance for structural parts, critical industrial applications often require that strength plus protection against static electricity. That's where Antero 840CN03 comes in. This specialized, high-performance thermoplastic is based on the same PEKK polymer family but features inherent Electrostatic Dissipative (ESD) properties. This is achieved by incorporating 3% carbon nanotube filler by weight into the PEKK formulation. This inclusion allows the material to safely conduct and dissipate static charges, preventing the buildup of static electricity that can damage sensitive electronic components during manufacturing or assembly. Antero 840CN03 retains the PEKK family's superior chemical and heat resistance, providing an ideal solution for critical applications that require protection against static discharge, such as electronic housings, fixtures for handling integrated circuits (ICs), and tooling used in satellite and avionics production.

| Available Colors | Tensile Strength, Yield (XZ MPa-ZX MPa) | Elongation at Break (XZ%-ZX%) | Heat Deflection Temperature (℃) @ 66 psi | Surface Resistivity (ohms) |

|---|---|---|---|---|

Available Colors Black | Tensile Strength, Yield (XZ MPa-ZX MPa) 94.9-56 | Elongation at Break (XZ%-ZX%) 2 | Heat Deflection Temperature (℃) @ 66 psi 149.5 | Surface Resistivity (ohms) 10^4Ω - 10^9Ω |

Properties achieved by running OEM materials and parameters on OEM Fortus equipment. See our FDM page for complete data sheets.

Cost-saving Tips

Here are some tips and considerations when choosing to print with PAEK family materials:

DFM: When designing parts for printing with FDM technology, special considerations are required. FDM machines construct parts from the bottom up, so any large overhangs will require support. Large internal cavities are not ideal as their support structures cannot be easily removed. Avoid designing parts where loads will be applied perpendicular to the printed layers. Despite the improved interlayer bonding of PAEK-based materials, the FDM process remains anisotropic in nature.

Choose the right material: The primary cost-saving strategy is to ensure you only select a PAEK grade if a core requirement, such as surviving temperatures above 150℃, exposure to corrosive fuels, or the necessity for Electrostatic Dissipation (ESD) cannot be met by a cheaper polymer. If your application requires a specialized function, select the specific grade that meets that requirement; otherwise, a lower-cost material offered by Xometry could provide the same value without the extra cost.

Finishes

Surface finishing options for PAEK and PEKK materials are limited; however, we are happy to explore custom finishes on a case-by-case basis.

Standard: Support structures are removed, and some light sanding may be performed at the support locations. FDM parts typically exhibit noticeable layer lines, known as stepping. If a smooth surface finish is required right off the machine, then other 3D printing technologies should be considered.

Other: Custom surface finishes, like painting and additional sanding, can be requested.

Mount made from VICTREX AM 200.

Need Custom PAEK or PEKK Parts?

Get instant pricing and lead times for these materials and others today!