PLA & PETG 3D Printing Service

Get instant online quotes on 3D Printed PLA and PETG parts. Free shipping on all US orders. Xometry is ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified.

About 3D Printing with PLA

PLA (polylactic acid) is one of the most popular and widely used materials in FDM 3D printing, particularly among beginners, due to its ease of use and generally low warping tendency. It is a bioplastic derived from renewable resources, such as corn starch or sugarcane, making it biodegradable and more environmentally friendly than many other thermoplastics. PLA offers good stiffness and a variety of vibrant color options, making it ideal for visual models, prototypes, and low-stress applications.

About 3D Printing with PETG

PETG (polyethylene terephthalate glycol) is a robust and highly versatile 3D printing material that effectively bridges the gap between the ease of printing offered by PLA and the mechanical strength and durability of ABS. It is a modification of PET (the plastic used in water bottles), with the addition of glycol to prevent crystallization, making it clear and easier to thermoform. PETG offers excellent impact resistance, good thermal stability, and superior chemical resistance, making it a popular choice for functional parts, mechanical components, and protective casings that require more resilience than PLA.

3D Printing with PLA and PETG at a Glance

| Applications | Advantages | Disadvantages | Minimum Lead Time | Comparative Cost | Max Part Size |

|---|---|---|---|---|---|

Applications

| Advantages

| Disadvantages

| Minimum Lead Time 3 Days | Comparative Cost $ (Low) | Max Part Size 10"x10"x10" (256 x 256 x 256 mm) |

PLA (FFF)

PLA is one of our lowest-cost materials. This, combined with its good stiffness and multiple color options, makes it a great value option for low-budget parts that don't require withstanding high heat, mechanical stresses, or load-bearing applications. It's a great pick for form and fit prototypes and visual models.

| Available Colors | Tensile Strength, Yield (XZ MPa-ZX MPa) | Elongation at Break (%) | Heat Deflection Temperature (℃) @ 66 psi |

|---|---|---|---|

Available Colors Black, Blue, Red, White | Tensile Strength, Yield (XZ MPa-ZX MPa) 50-37 | Elongation at Break (%) 2.9-1.9 | Heat Deflection Temperature (℃) @ 66 psi 55 |

Data is based on generic PLA filament for FFF printers and is for reference only. See our FDM page for complete data sheets.

PETG (FFF)

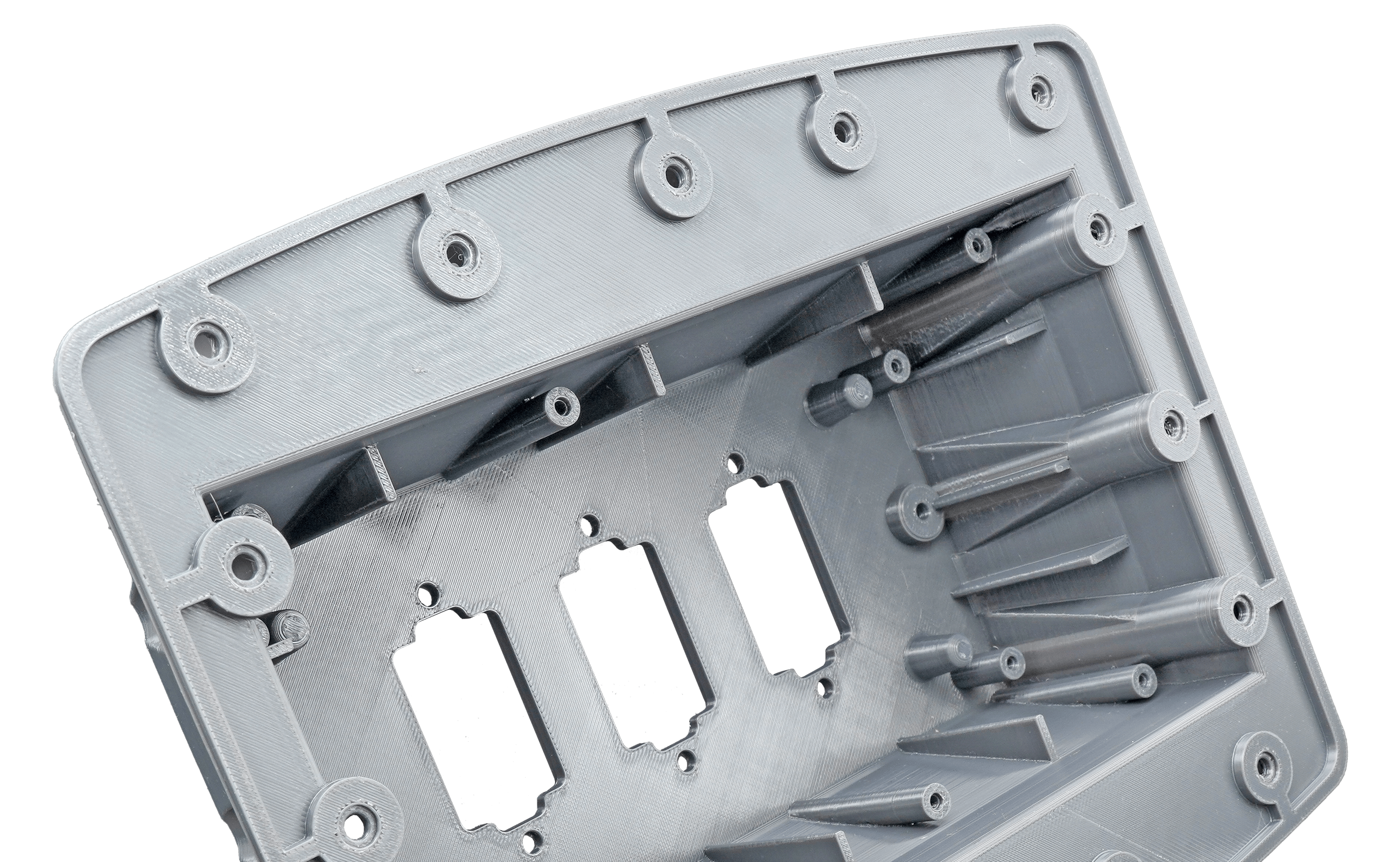

PETG is a highly versatile and affordable material that falls between PLA and ABS in terms of properties. It offers excellent value for functional parts by combining the relative ease of printing (similar to PLA) with significantly improved durability, impact resistance, and higher heat tolerance than PLA. This makes it an ideal, cost-effective choice for components that require moderate mechanical stress and resilience, such as protective enclosures, functional prototypes, and tooling where PLA might fail.

| Available Colors | Tensile Strength, Yield (XZ MPa-ZX MPa) | Elongation at Break (XZ%-ZX%) | Heat Deflection Temperature (℃) @ 66 psi |

|---|---|---|---|

Available Colors White, Black, Dark Grey, Blue, Red, Yellow | Tensile Strength, Yield (XZ MPa-ZX MPa) 50-47 | Elongation at Break (XZ%-ZX%) 5.1% | Heat Deflection Temperature (℃) @ 66 psi 68 |

Data is based on generic PETG filament for FFF printers and is for reference only. See our FDM page for complete data sheets.

Cost-saving Tips

Here are some tips and considerations when choosing to print with PLA or PETG:

DFM: When designing parts for printing with FDM/FFF technology, special considerations are required. These machines construct parts from the bottom up, so large overhangs will require support. Unlike many of our other FDM materials, which can use soluble supports, PLA and PETG use break-away supports. Try to make your designs self-supporting whenever possible, and avoid internal cavities that could result in trapped support structures.

Choose the right material: Consider the function of your parts and what they need to withstand. While it's tempting to choose PETG or other materials for their improved material properties, in many cases, you can save money by opting for PLA for low-stress, low-heat applications.

Finishes

Surface finishing options for PLA and PETG are limited; however, a wide range of colors is available for both materials.

Standard: Support structures are removed, and some light sanding may be performed at the support locations. FDM/FFF parts typically exhibit noticeable layer lines, known as stepping. If a smooth surface finish is required right off the machine, then other 3D printing technologies should be considered.

Other: Custom surface finishes, like painting and additional sanding, can be requested.

PLA in various colors.

Need Custom PLA or PETG Parts?

Get instant pricing and lead times for these materials and others today!