Micro Machining Services

Precision micro CNC milling and turning | Miniature features with intricate detailing | Complex components with fine surface finishes | ISO 9001, ISO 13485, IATF 16949, AS9100D certified. ITAR registered.

Xometry provides specialized CNC micro machining for parts that require extreme detail and sub-millimeter features. We bridge the gap between standard machining and micro-manufacturing, allowing you to achieve complex, tiny geometries in both metals and rigid plastics. Access instant pricing, lead times, and expert engineering feedback by uploading your 3D CAD to the Xometry Instant Quoting Engine®. We support your product lifecycle from R&D to full-scale production, maintaining strict compliance through our ISO 9001, ISO 13485, IATF 16949, and AS9100D-certified quality management system.

What Is Micro Machining?

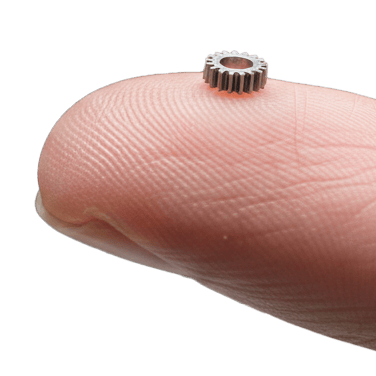

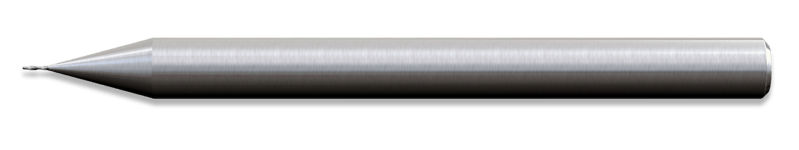

Micro machining is a specialized subtractive manufacturing process for producing components with extremely small dimensions and intricate details. While it operates on the same principles as conventional CNC milling and turning, it utilizes ultra-precise equipment featuring high-speed spindles and miniature tooling, often with cutter diameters smaller than 0.010”. This capability facilitates optimal chip loads and cuts clean micro-scale features.

This level of precision is critical for industries pushing the boundaries of miniaturization, including medical device manufacturing, aerospace, and micro-electronics. Common applications range from surgical end-effectors and implantable components to microfluidic channels and fiber optic housings. Xometry simplifies sourcing these challenging parts by connecting you with a vetted network of partners with specialized tooling and inspection equipment for micro-manufacturing, ensuring your parts meet strict quality standards every time.

Need micro machined parts?

Upload your 3D CAD to get instant pricing and lead times.

Materials Available for Micro Machining

Aluminum

Aluminum is well-suited for micro machining due to its exceptional machinability and dimensional stability. Its excellent strength-to-weight ratio makes it ideal for miniature structural components and housings. While standard grades like 6061-T6 machine cleanly, harder alloys like 7075 are preferred for micro-features as they produce smaller, more manageable chips, ensuring finer edge retention and surface finishes.

Popular aluminum alloys Xometry can micro machine include:

- Aluminum 6061

- Aluminum 5052

- Aluminum 2024

- Aluminum 6063

- Aluminum 7050

- Aluminum 7075

Brass, Bronze & Copper

Copper alloys offer a unique blend of electrical conductivity and lubricity essential for micro-contacts and wear components. Brass C360 is often considered the gold standard for micro-turned parts due to its tendency to form small chips that don't risk entangling tiny cutters. Conversely, pure copper (C101/C110) offers superior conductivity but requires specialized cutting strategies to manage its ductility and prevent burr formation on delicate features.

We offer the following copper-based materials:

- Copper 101

- Copper 260 (Brass)

- Copper C110

- Copper C932 (Bronze)

- Copper C360 (Brass)

Garolite

Garolite is a high-strength, glass-reinforced epoxy laminate frequently used in electronics and insulating spacers. Its layered structure provides excellent thermal and electrical insulation. However, due to its abrasive glass content, micro machining Garolite typically requires diamond-coated tooling to maintain tolerances and prevent rapid edge degradation. We recommend this material primarily for flat, structural insulators rather than for parts that require intricate 3D contours.

Xometry offers the following grades of Garolite:

- Garolite G10 (FR4)

- Garolite G10

- Garolite G11 (FR5)

Plastics

Engineering plastics are invaluable for tiny medical and electronic components that require biocompatibility or dielectric properties. Delrin (Acetal) and PEEK are excellent choices for micro-machined plastic parts, as their rigidity allows them to be machined with metal-like precision with minimal tool deflection. Softer plastics like HDPE or Polypropylene may require looser tolerance expectations due to their natural tendency to flex during machining.

Xometry's manufacturing network supports a wide array of plastics for micro machining, such as:

- ABS

- Acrylic

- Acetal (POM)

- Delrin 100 (AF)

- Delrin 150

- HDPE

- Nylon 6/6

- Polycarbonate

- PEEK / USP Cass VI TECAPEEK / PEEK GF30

- Polypropylene

- UHMW PE

- ULTEM 1000

- ULTEM 2300

Stainless Steel

Stainless steel is foundational in the medical device industry, offering high corrosion resistance and strength for surgical instruments and implants. In micro machining, free-machining grades like 303 are favored for their ease of cutting. Precipitation-hardening grades like 17-4 PH provide superior durability but require rigid setups and specialized tooling to prevent work hardening.

Our stainless steel options include:

- Stainless Steel 15-5 PH

- Stainless Steel 17-4 PH

- 300 Series Stainless Steel (e.g., 303, 304, 316)

- 400 Series Stainless Steel (e.g., 410, 416, 420, 440C)

- NITRONIC® 60

Steel

Carbon and tool steels provide the necessary hardness and wear resistance for micro-mechanical parts such as gears, shafts, and mold inserts. Instead of focusing on maximizing material removal rates, micro-machining steel emphasizes achieving superior surface quality and maintaining precise edge definition. We recommend cold-finished or alloy steels, such as 4140, over hot-rolled varieties to ensure a consistent grain structure that supports micron-level detailing.

Xometry can micro machine steel materials such as:

- Steel 1018

- Steel 1215

- Steel 4130

- Steel 4140

- Steel 4340

- Tool Steel A2

- Tool Steel O1

Titanium

Titanium is prized in aerospace and medical sectors for its incredible strength-to-weight ratio and biocompatibility. While notoriously difficult to machine, it is highly suitable for micro-applications when processed correctly. Grade 5 (Ti-6Al-4V) is particularly effective for micro-machined parts; its hardness actually helps produce a cleaner shear during cutting compared to softer commercially pure grades, though it necessitates advanced thermal management to preserve tool life.

We offer popular grades of titanium, including:

- Titanium Grade 2

- Titanium Grade 5

Finishing Options for Micro Machined Parts

Post-processing micro-machined parts requires careful consideration of dimensional tolerances and durability. Standard finishes that work well for larger components can often compromise the delicate features of a micro-machined piece.

To ensure success, we recommend avoiding aggressive mechanical processes, such as heavy bead blasting, and coatings that add significant thickness (e.g., powder coating). The finishing options listed below are low-risk solutions that preserve the integrity and precision of tiny components:

Essential for stainless steel medical parts. It removes surface iron and adds negligible thickness at about .0000001”. Conforms to ASTM A967, AMS-QQ-P-35, MIL-STD-171, ASTM A380, or AMS 2700.

Enhances corrosion resistance and conductivity properties while adding very little thickness, typically 0.00001”-0.00004”. Conforms to MIL-DTL-5541, TYPE I/II CLASS 1A or CLASS 3 as specified.

Removes a tiny amount of material to smooth the surface. This is an excellent choice for micro machining because it deburrs the part microscopically without mechanical force. Conforms to ASTM B912-02.

Increases corrosion resistance and surface hardness. Type II adds approximately 0.0002”–0.0005” of thickness. For micro-machined components, it's important to account for dimensional growth and racking locations.

Metal platings provide durable, uniform protection while preserving the part’s precision and surface finish. Electroless nickel, gold, silver, and zinc can be applied to enhance corrosion resistance, conductivity, and wear resistance.

Applications of Micro Machining

Precision Miniaturization

Supports product downsizing by delivering critical components with sub-millimeter features, allowing for compact devices and assemblies.

Creating Micro-Geometries

Micro machining can resolve complex 3D contours, thin walls, and micron-level details that standard methods cannot achieve.

High-Accuracy Applications

Produces rigid, tight-tolerance components for sensing, actuation, and optics, ensuring reliable performance across scientific and industrial applications.

Micro Machining Across Industries

Micro machining helps reduce weight and size for critical airborne and space systems. It's ideal for producing ruggedized hardware, such as fuel metering valves, gyroscope housings, and satellite sensor mounts.

Precision machining supports the strict requirements of minimally invasive surgery and long-term implantation. This process is used to produce biocompatible components such as surgical robot end-effectors, bone screws, and dental abutments that must meet rigorous ISO 13485 quality standards.

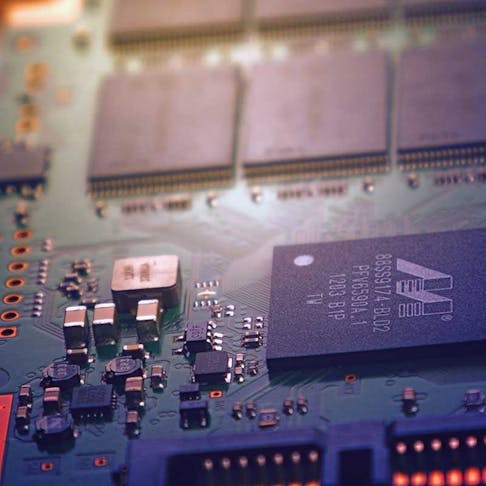

This process enables higher circuit density and efficient thermal management for next-gen devices. It enables the fabrication of intricate conductive and dissipative parts, including IC test sockets, microconnectors, and fiber-optic ferrules, ensuring reliable contact points for data transfer.

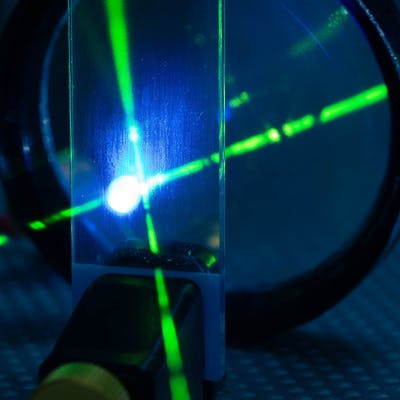

Micro machining produces tiny components with the rigid dimensional stability required to maintain perfect alignment in light-based systems. It is essential for creating high-accuracy structural components, such as laser diode mounts, aperture plates, and lens barrels, used in advanced imaging and laser systems.

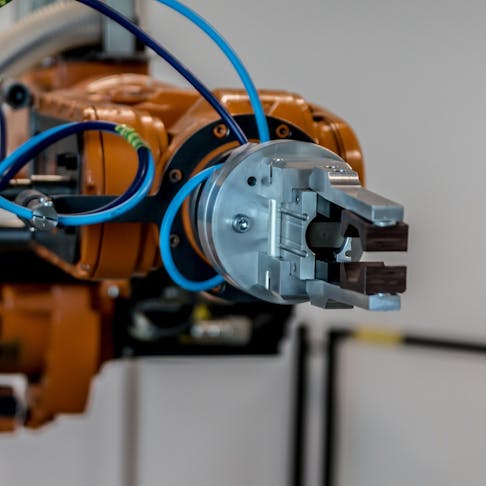

Micro machining enables the creation of compact, lightweight actuation and sensing systems for autonomous machines. This process is frequently used to fabricate high-strength mechanical components, such as miniature gearboxes, micro-gripper end-effectors, and tactile sensor housings, enabling robots to perform delicate tasks with high dexterity.

Other Machining Services From Xometry

Custom Online CNC Machining Services

CNC Routing Services by Xometry

Swiss Machining Services

Why Choose Xometry for Micro Machining Services?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get started with our easy-to-use platform and let our experts take care of managing the project from locating the right manufacturing partner to delivery logistics.

Vetted Network

We are ISO 9001, ISO 13485, IATF 16949, and AS9100D certified. Only the top shops that apply to become suppliers make it through our qualification process.