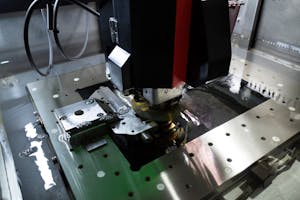

Precision CNC Machining Services

Instant quotes on ultra-precise CNC-machined components for critical applications | Fast turnaround prototype and production parts in days | Free standard shipping on all US orders | International prototype pricing includes tariffs | ISO 9001:2015, ISO 13485, IATF 16949:2016, AS9100D certified. ITAR registered.

Precision CNC Machining by Xometry

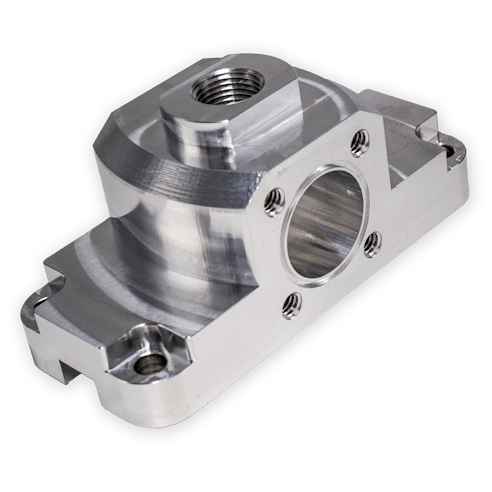

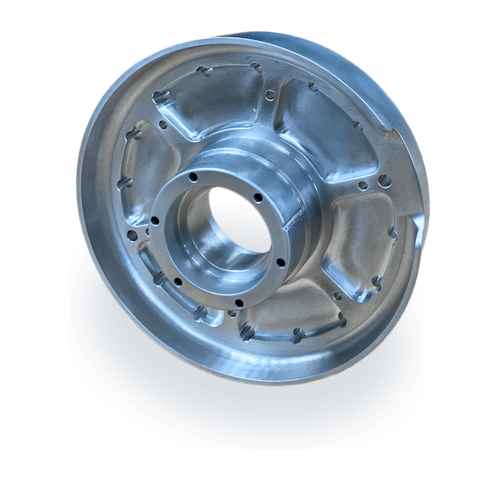

Xometry offers on-demand precision CNC machining for custom, high-accuracy parts built to meet the most demanding requirements. Whether you're prototyping or scaling to production, our extensive network of 10,000+ vetted suppliers enables fast, reliable access to CNC-machined components with tight tolerances, smooth surface finishes, and consistent dimensional accuracy. From metals to plastics, we support complex geometries and critical applications across automotive, aerospace, medical, and other industries.

Upload your CAD file to the Xometry Instant Quoting Engine® to get instant pricing, lead time, and DFM feedback for your precision parts. With end-to-end services backed by an ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified quality management system, you can trust Xometry to deliver on your needs.

What is Precision CNC Machining?

Precision CNC machining is a specialized form of computer numerical control (CNC) machining that focuses on producing parts with extremely tight tolerances, high repeatability, and exceptional surface finishes. Standard machining typically prioritizes speed or cost for less critical applications, whereas precision CNC machining is designed for components where even the smallest dimensional deviation can impact performance or safety.

This level of precision is essential for ensuring each part meets strict engineering specifications and for creating complex geometries, micro-scale features, and high-accuracy parts used in mission-critical industries like aerospace, medical devices, electronics, and optics.

Our Precision Machining Capabilities

| Capability | Description |

|---|---|

Capability Precision Tolerances | Description Xometry can manufacture and inspect to tight tolerances, including sub +/- 0.001" tolerances, per your drawing specifications and GD&T callouts. |

Capability Surface Finishes | Description We automatically quote surface roughnesses down to 16μin Ra and can support lower values upon manual review. |

Capability Threads and Tapped Holes | Description Xometry accommodates any standard thread size. We can also machine custom thread forms. |

Capability Edge Condition | Description Unless otherwise requested, sharp edges are broken and deburred by default. |

Capability Minimum Feature Size | Description Our recommendation is to keep features 0.020” (0.50 mm) or larger. This may vary depending on part geometry and chosen material. |

Capability Maximum Part Size | Description Typically, milled parts up to 80” x 48” x 24” (2,032 x 1,219 x 610 mm). Lathe parts up to 62” (1,575 mm) length and 32” (813 mm) diameter. Larger parts can be reviewed on a case-by-case basis. |

For more information, please see our manufacturing standards.

Materials for Precision CNC Machining

Selecting the right material impacts everything from tolerance capabilities and thermal stability to machining efficiency and final part cost. Here are just a few of the suitable options Xometry offers for precision-machined parts. For more materials, see our material library.

Metals

Aluminum Alloys

Aluminum is a go-to material for precision CNC machining due to its lightweight nature, corrosion resistance, and excellent machinability. Grades like 6061 and 7075 offer high strength and dimensional stability, allowing for tight tolerances and fine surface finishes. These properties make aluminum ideal for aerospace components, automotive housings, brackets, and heat sinks.

Stainless Steel

Stainless steel is valued in precision CNC machining for its strength, corrosion resistance, and ability to hold tight tolerances under stress. Grades like 304, 316, and 17-4 PH are commonly used across medical devices, food-grade equipment, and high-wear components. Typical applications include surgical tools, enclosures, shafts, and fasteners.

Steel Alloys

Steel alloys, including carbon steels like 1018 and alloy steels like 4140, offer a strong combination of hardness, strength, and machinability. These materials are commonly used in precision CNC machining for structural, automotive, and industrial applications. Typical parts include gears, shafts, brackets, and custom tooling.

Titanium

Titanium is prized for its exceptional strength-to-weight ratio and corrosion resistance, making it ideal for aerospace, medical implants, and defense applications. While more difficult and costly to machine, titanium delivers high performance in demanding environments. Common grades Xometry offers include Grade 2 and Grade 5 (Ti-6Al-4V). Structural aircraft components, surgical implants, and high-performance fasteners are often made out of titanium.

Plastics

Delrin 150 (Acetal)

Delrin is a type of acetal known for its excellent machinability, low friction, and high dimensional stability, allowing us to automatically quote tight tolerances down to ±0.001" for this material. Its moisture resistance and wear properties make it well-suited for applications like bushings, gears, bearings, and custom mechanical components.

ABS

ABS is a lower-cost, general-purpose plastic commonly used in early-stage product development for its good machinability, moderate strength, and affordability. While it has slightly less dimensional stability than materials like Delrin, ABS can still be precision machined to tight tolerances. It is a solid choice for prototypes, housings, brackets, and test fixtures where balancing cost and accuracy is key.

PEEK

Known for its exceptional mechanical strength, thermal stability, and chemical resistance, PEEK is a high-performance engineering plastic. It’s well-suited for demanding precision applications in aerospace, semiconductor, and industrial environments, where it’s commonly used for high-temperature bushings, electrical insulators, and fluid-handling components. For medical applications, we offer TECAPEEK, a USP Class VI compliant variant ideal for surgical implants and other biocompatible parts.

Advantages of Precision CNC Machining

Precision CNC machining offers a suite of advantages over traditional machining. The primary benefits include:

- Tight Tolerances

- Repeatability

- Superior Surface Finishes

- Quality Control

Tight Tolerances

Where typical machining tolerances are in the range of ±0.005", our precision CNC machining offerings are focused on hitting extra-tight tolerances in the sub ±0.001" range.

Repeatability

Precision machining makes consistent, repeatable production runs possible, even for components with tight tolerances, thanks to specialized tooling, fixturing, and machine setups.

Superior Surface Finishes

Machining high-precision components often necessitates optimized cutting parameters, tight machine calibration, and additional finishing passes with fresh, sharp tooling. These factors inherently contribute to improved as-machined surface finishes that exceed our 125μin Ra standard. If requested, we can target surface roughness down to 16μin or better.

Quality Control

Producing precision parts requires measuring and validating results throughout the process. That’s why precision machining often integrates real-time monitoring, probing, and in-process quality checks to dial in tight features and critical dimensions, helping catch issues early, long before final inspection.

Precision CNC Machining Applications

Precision CNC machining is essential for producing high-accuracy parts used in industries where performance, safety, and reliability are critical. It's commonly applied in aerospace, medical devices, electronics, and other fields that demand tight tolerances and consistent quality.

Common applications include:

- Aerospace components

- Medical devices and implants

- Robotics and automation

- Optics and electronics housings

- Defense and military parts

- Automotive engine components

- Industrial machinery and tooling

How Precision CNC Machining Works

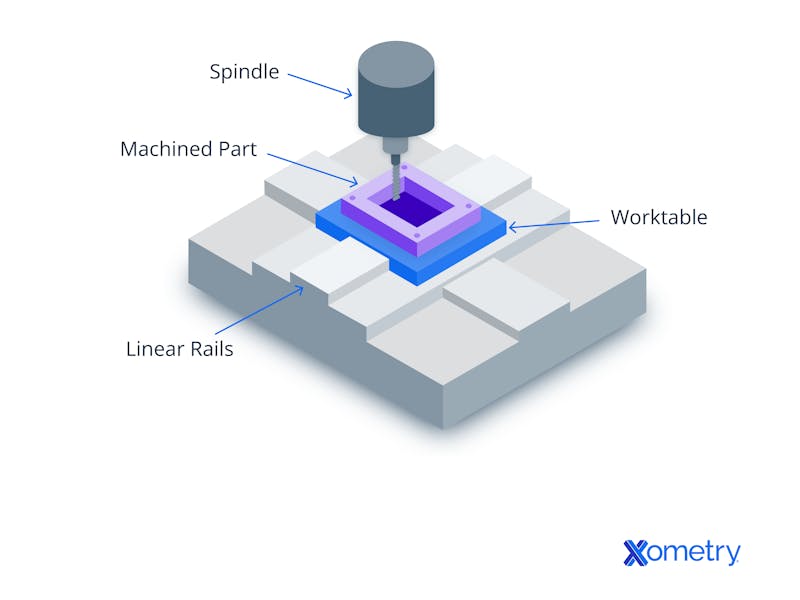

Precision CNC machining begins with your 3D CAD model. We take this design and use CAM (Computer-Aided Manufacturing) software to translate it into toolpaths and G-code that control the machine’s movements. Depending on the complexity and geometry of the part, these instructions guide various types of CNC machines, including 3-axis mills, 5-axis machining centers, and Swiss lathes.

CNC machining is a subtractive manufacturing process that removes material from a solid piece of raw material using high-speed cutting tools. Common strategies include roughing passes for bulk removal and finishing passes for fine detail and smooth surfaces. Tooling is selected based on material, feature type, and tolerance requirements to ensure accuracy and surface finish. Throughout the process, precision setups, fixturing, and in-process probing help maintain tight dimensional control from the first cut to the final part.

Design Guidelines for Precision CNC Machining

Designing parts for precision CNC machining requires thoughtful consideration of tolerances, surface finish requirements, and overall part geometry. These factors play a key role in determining how efficiently and accurately a part can be produced. Understanding how design decisions impact the machining process is essential for achieving optimal results in both performance and manufacturability.

Tolerance and Surface Finish

Precision CNC machining allows for much tighter tolerances than standard machining, typically ±0.001" or better. While tighter tolerances improve function and repeatability, they also increase cost and complexity.

Surface finishes, measured in Ra (roughness average), impact part performance in sealing, sliding, or mating features. Standard finishes range from 63–125 µin Ra, while precision surfaces may require 16 µin Ra or finer. These are achieved through optimized tooling, fine passes, and sometimes secondary finishing processes, which can add additional time and cost the finer your requirements become.

Pro Tip: Only apply tight tolerance and surface finish requirements where they are truly necessary to avoid excess manufacturing costs.

Part Geometry and Features

Part geometry directly affects how easily and accurately a part can be machined. Features like thin walls, deep pockets, narrow slots, and closely spaced holes can introduce challenges such as tool deflection, chatter, and difficulty holding tolerances, especially with softer materials or long-reach tooling. Hard-to-reach threads, undercuts, and intricate internal features often require specialized tooling or multi-axis machining, increasing setup time and cost.

Pro Tip: To ensure precision and minimize machining challenges, design with stable geometries; avoid overly thin walls, deep pockets, and tightly clustered features that can increase deflection, chatter, and setup complexity.

Looking for more CNC design tips?

Precision CNC Machining Inspection and Quality Control

Quality control is central to precision CNC machining, ensuring every part meets exact specifications. The process often starts with in-process inspections, such as on-machine probing or real-time monitoring, to verify critical dimensions during production. Xometry offers various quality control options, such as First Article Inspections (FAI), which are performed on initial runs to validate the entire manufacturing process before full-scale production.

For final verification, coordinate measuring machines (CMMs) and other precision metrology tools check dimensions and geometries, often following GD&T standards to capture form, fit, and function requirements. Our quality management system is ITAR registered and certified to ISO 9001, ISO 13485, and AS9100, which ensures we meet qualification requirements for various regulated industries that require precision parts.

Xometry Alternatives to Precision Machining

Wire EDM Machining Service

Custom Plastic Injection Molding Service

Sheet Metal Fabrication Services

Why Choose Xometry for Precision CNC Machining?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get started with our easy-to-use platform and let our experts take care of managing the project from locating the right manufacturing partner to delivery logistics.

Vetted Network

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

Frequently Asked Questions About Precision CNC Machining

What information do I need to provide to get an accurate quote?

To get a precision CNC machining quote, upload your 3D CAD file (STEP, SLDPRT, IPT, PRT, etc.) and any supporting drawings to the Xometry Instant Quoting Engine®. Set the process to "CNC " and fully configure your parts, ensuring features like tight tolerances, threads, and part markings are specified.

What tolerances can you achieve with precision machining?

Our standard tolerance for CNC-machined parts is +/- 0.005". Auto-quoting is available for tolerances as tight as +/- 0.001" for most materials, with sub +/- 0.001" tolerances available after manual review.

What materials can you machine?

Xometry offers all standard commodity materials, including various aluminum alloys, copper, steel, stainless steel, titanium, plastics, and composites. For a complete list of materials, see our materials library. We are also happy to explore customer-provided material or custom material requests.

What is your typical lead time?

The lead time for precision CNC-machined orders starts at three business days and increases from there depending on project-specific requirements such as quantity, part complexity, and other specifications.

Can you support both prototyping and high-volume production?

Yes! Xometry supports everything from smaller prototype runs to high-volume production. CNC orders have no quantity minimums, allowing you to get quotes for orders anywhere from one-offs to production runs.

Do you provide design support or manufacturability feedback?

Yes! The Xometry Instant Quoting Engine® provides you with instant DFM warnings, and our team of engineers will contact you if any manufacturability concerns are found with your order.

What quality control processes do you offer?

Xometry offers multiple options for quality control and part inspections. From standard inspections to first article inspections with reports to custom requests, we can accommodate your quality assurance needs. Read our article about our inspection options to learn more.

Do you support ITAR or ISO-certified projects?

Xometry is proud to be ITAR-registered, ISO 9001:2015, ISO 13485:2016, IATF 16949:2016, AS9100D, and CMMC Level 2 certified. As you build your quote, you can specify certification and qualification requirements by selecting from the corresponding options.