Swiss Machining Services

High-quality Swiss-type machining | Intricate and complex mill-turn geometries | Excellent surface finishes | International prototype pricing includes tariffs | ISO 9001, ISO 13485, IATF 16949, AS9100D certified. ITAR registered.

Xometry delivers custom Swiss machining services for complex, small-diameter parts through our vetted manufacturing network. By utilizing guide bushing technology to minimize deflection, we achieve rapid, high-precision results for slender components that standard lathes cannot match. Upload a CAD file to the Xometry Instant Quoting Engine® for real-time pricing and design feedback. From medical instruments to aerospace fittings, we ensure quality from prototype to production with our ISO 9001, ISO 13485, IATF 16949, and AS9100D-certified quality management system.

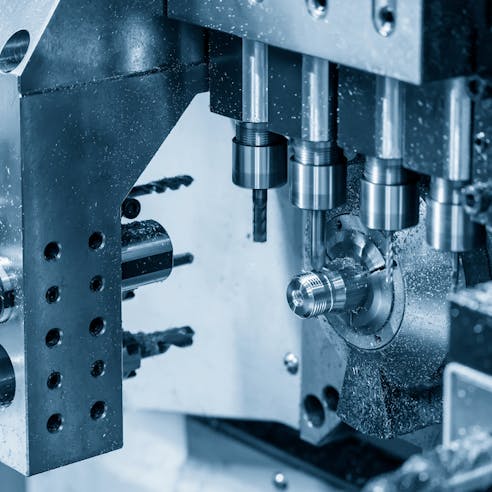

What Is Swiss Machining?

Swiss machining is a material-removal process that uses advanced CNC-controlled sliding-head lathes to perform cutting operations along and perpendicular to the workpiece axis. Unlike traditional setups, in which much of the bar stock is exposed, Swiss-type machines use a guide bushing that exposes only the section being machined. This minimal stick-out drastically reduces vibration and deflection, enabling simultaneous machining processes that deliver higher stability and superior precision.

Due to this efficiency, Swiss-type machining is the premier fabrication method for complex, small-diameter components in the automotive, medical, and aerospace industries. Xometry’s capabilities are compatible with a vast range of materials, supporting applications from surgical and dental instruments to fuel injection components and hydraulic valve spools. Our extensive network of manufacturing partners enables us to supply these high-quality Swiss-machined parts globally, meeting your project needs wherever you are.

Materials That Can Be Swiss Machined

Virtually any material that can be machined using a standard lathe or mill can be Swiss machined. Some examples of materials Xometry can work with are listed below:

Aluminum

Aluminum is a common workpiece material used in Swiss machining. It has a high machinability rating, making it a great choice. The process is often used to produce aerospace parts from aluminum. Parts such as engine components, like fuel line fittings, standoffs, fasteners, and more, are usually made from aluminum using Swiss machining processes.

Brass

Brass, especially C360, is commonly used in Swiss machining to make brass parts for hardware. Examples include: screws and washers, valve bodies, lock cylinders, electrical terminals, and more.

Copper

Copper is often used in Swiss machining to make parts for heat exchangers, contact pins, electrical connectors, terminals, and more.

Stainless Steel

Stainless steel is utilized in numerous industries for its exceptional strength and resistance to corrosion. Stainless steel parts often made by Swiss machining include: surgical and dental instruments, pipe fittings, nozzles, and bearings.

Superalloys

Superalloys such as Inconel®, Monel®, and Hastelloy are often used in extreme environments, including jet engines, chemical processing equipment, gas turbines, and more. Swiss machining is highly reliable and repeatable, making it the ideal solution for machining these expensive materials into critical components where precision is key.

Titanium

Titanium is valued for its high strength-to-weight ratio, corrosion resistance, and biocompatibility, making it a staple in aerospace, automotive, and medical industries. While titanium can be challenging to machine, Swiss machining effectively converts this tough material into critical components like specialty fasteners, hydraulic fittings, bone screws, and dental implants. This process is ideal for producing high-precision titanium parts where weight reduction and material integrity are essential.

Acetal

Acetal (POM), commonly known by the brand name Delrin®, is a widely used thermoplastic in Swiss machining. It is valued for its high stiffness, low friction, and excellent dimensional stability. Swiss-machined Acetal and Delrin® components include valves and fittings, as well as gears, bearings, knobs, and more.

Nylon

Nylon is a thermoplastic valued for its high strength, chemical resistance, and exceptional wear resistance. Nylon Swiss-machined components include: gears, bushings, insulators, rollers, and more.

PTFE (Teflon™)

PTFE (polytetrafluoroethylene) is a fluoropolymer known for its exceptional chemical resistance, thermal and electrical insulation properties, UV resistance, and low coefficient of friction. This makes PTFE ideal for Swiss-machined parts such as electrical insulators, bushings, bearings, and seals.

Ultem®

Ultem® is a trademark polyetherimide resin manufactured by Sabic. Ultem® is valued for its excellent mechanical properties and dimensional stability even when exposed to extreme temperatures. Swiss machining is used to produce Ultem® parts, including medical instrument components, electrical connectors, and insulators.

PEEK

PEEK (polyetheretherketone) is a high-performance thermoplastic renowned for its excellent mechanical properties, dimensional stability, ability to be used at high temperatures, and resistance to hydrolysis. Examples of Swiss-machined PEEK parts include: gears, rollers, bushings, seals, electrical connectors, and pump and valve components.

Looking For Swiss Machining?

Benefits of Swiss Machining

There are many benefits and advantages to Swiss machining. These include:

- High Precision & Tight Tolerances

- Complex Geometries

- High Production Speed

- Cost-Effective Consistency

High Precision & Tight Tolerances

Swiss machining uses a guide bushing to support the workpiece near the cutting tool, minimizing deflection and vibration. This stability allows for exceptional accuracy on long, slender parts, routinely achieving tolerances as tight as ±0.001” or better.

Complex Geometries

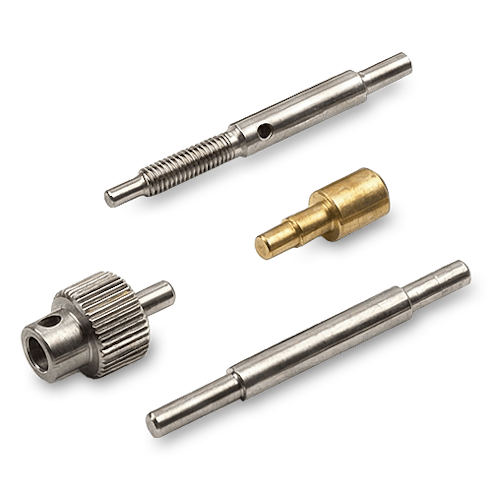

Swiss-type machines can perform cutting operations both axially and perpendicularly to the workpiece in a single setup. This versatility eliminates the need for secondary operations, enabling the efficient production of intricate parts such as orthopedic implants, watch gears, and aerospace fasteners.

High Production Speed

Swiss machining achieves rapid cycle times by performing multiple operations simultaneously (e.g., milling and turning). Paired with automatic bar loaders for "lights-out" manufacturing, this process is highly automated and efficient for high-volume production.

Cost-Effective Consistency

Because tool stick-out and vibration are minimized, Swiss machining offers superior process stability and exceptionally low scrap rates. This reliability ensures that parts remain consistent over long production runs, minimizing material waste and lowering overall costs.

Industry Applications of Swiss Machining

Swiss machining is well-suited to producing small aerospace parts due to its ability to meet tight tolerances on exotic materials. Common aerospace applications include fuel injection nozzles, hydraulic valve spools, electrical connector bodies, and specialty fasteners.

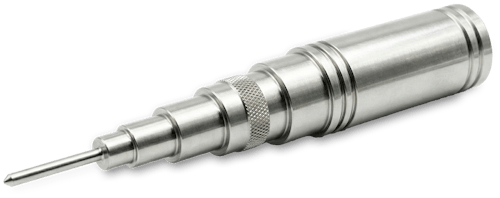

Parts in the medical industry are often small and must be fabricated to precise tolerances for safety and performance. Swiss machining is the standard method for manufacturing critical components, including surgical and dental instruments, bone screws, spinal implants, and pacemaker components.

The automotive industry relies on Swiss machining for high-precision fuel and safety systems. Common applications include fuel injector components, ABS brake valve spools, sensor housings, and hydraulic transmission valves.

The electronics industry relies on Swiss machining for high-precision connectivity solutions. Common applications include connector pins and sockets, RF connector bodies, sensor housings, and insulators.

Robotics relies on high-precision, lightweight components to enable complex motion in compact spaces. Swiss machining is the ideal process for manufacturing these intricate drive systems, including applications like miniature motor shafts, planetary gear components, hydraulic micro-valves, and end-effector pins.

Alternative Machining Services by Xometry

Custom Online CNC Machining Services

CNC Turning Service

Custom CNC Milling Services

Why Choose Xometry for Swiss Machining Services?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get started with our easy-to-use platform and let our experts take care of managing the project from locating the right manufacturing partner to delivery logistics.

Vetted Network

We are ISO 9001, ISO 13485, IATF 16949, and AS9100D certified. Only the top shops that apply to become suppliers make it through our qualification process.

Instant Quoting for Swiss-Machined Parts

Get instant pricing and lead times for Swiss-machined parts today!

Copyright and Trademark Notices

- Monel® and Inconel® are registered trademarks of Special Metals Corporation.

- Delrin® is a registered trademark of Delrin USA LLC.

- Ultem® is a registered trademark of SHPP Global Technologies B.V.

- Teflon™ is a registered trademark of The Chemours Company FC, LLC.