Compression Molding Service

Durable, High-Strength Parts for Demanding Applications

Compression Molding Services by Xometry

Compression molding is a versatile production process that Xometry offers for manufacturing strong, durable, and complex parts. It involves placing pre-measured material—such as silicone, EPDM, or NBR—into a heated mold cavity, which is then closed under pressure until the part cures.

This method is ideal for creating custom seals, gaskets, and rubber components with excellent surface finish, dimensional stability, and heat, chemical, and corrosion resistance. The process is helpful for several industries, including automotive, aerospace, electrical, and medical.

Xometry connects you with top compression molding suppliers, ensuring precise, cost-effective results. We manage complex projects from design to production with expert guidance and reliable support.

Compression Molding Materials

While compression molding carbon fiber and plastic compression molding are both viable applications of the process, at Xometry, our expertise lies in molding rubber elastomers; materials prized for their flexibility, resilience, and resistance to heat, chemicals, and wear. This focus allows us to deliver high-performance parts tailored for demanding environments across a range of industries.

Rubber Elastomers Offered by Xometry

Silicone: Silicone offers excellent flexibility and stability across a wide temperature range, making it ideal for applications requiring thermal resistance, electrical insulation, and biocompatibility.

NBR (Nitrile Butadiene Rubber): Known for its superior resistance to oils, fuels, and other hydrocarbons, it's a go-to choice for seals and gaskets in automotive and industrial environments.

HNBR (Hydrogenated Nitrile Butadiene Rubber): HNBR combines the oil and chemical resistance of NBR with improved heat and ozone resistance, offering enhanced durability in high-performance sealing and dynamic applications.

FKM (Viton®) - FKM provides outstanding resistance to high temperatures, chemicals, and aggressive fluids, making it a popular choice among aerospace and automotive engineers.

EPDM (Ethylene Propylene Diene Monomer): Highly resistant to weathering, ozone, and UV. It's an excellent choice for outdoor and water-resistant applications, including HVAC and automotive systems.

IIR (Butyl Rubber): Its low gas permeability and excellent resistance to moisture and chemicals make it suitable for airtight seals, pharmaceutical closures, and vibration damping.

CR (Chloroprene / Neoprene): Provides a balanced mix of weather, ozone, oil, and flame resistance, commonly used in automotive, marine, and industrial applications.

FVMQ (Fluorosilicone): FVMQ maintains silicone's flexibility and thermal stability while adding fuel and oil resistance, making it ideal for aerospace and automotive fuel system components.

FFKM (Perfluoroelastomer): FFKM offers the highest level of chemical and thermal resistance among elastomers, making it the material of choice for critical sealing applications in semiconductor, chemical, and pharmaceutical industries.

Compression Molding Advantages

Understanding the key advantages of this molding technique helps explain why it’s become a popular manufacturing method. Below are some primary reasons engineers rely on it to meet demanding project requirements:

- Creates Unique Shapes

- Cost Effective

- Supports Variable Thicknesses

Creates Unique Shapes

Compression molding enables the production of complex forms that are challenging to achieve with other methods. It allows for intricate details, undercuts, and varying contours within a single part, allowing designers to tailor parts precisely to functional and aesthetic specifications.

Cost Effective

This manufacturing method uses relatively simple tooling and generates minimal material waste, making it a cost-effective option for medium- to high-volume production. The controlled molding process also produces high-quality surface finishes, reducing or eliminating the need for costly post-machining or secondary finishing operations.

Supports Variable Thicknesses

The compression molding technique supports parts with walls that can vary in thickness within a single mold, allowing designs that optimize strength and weight. This flexibility accommodates complex geometries and functional variations that can be difficult to achieve using other processes.

Compression Molding Applications

Compression molded products are used across a wide range of industries that require durable, precisely formed components capable of withstanding specific environmental, mechanical, or regulatory demands.

Common applications include:

- Dental and Medical

- Consumer Products

- Food and Beverage

- Manufacturing

Dental and Medical

In the dental and medical sectors, compression molding is ideal for producing biocompatible seals, diaphragms, and flexible components where cleanliness and precision are essential. The process ensures consistent part quality and smooth surface finishes, both critical for hygienic applications. Silicone is a common choice due to its excellent thermal stability, chemical resistance, and proven safety in medical environments.

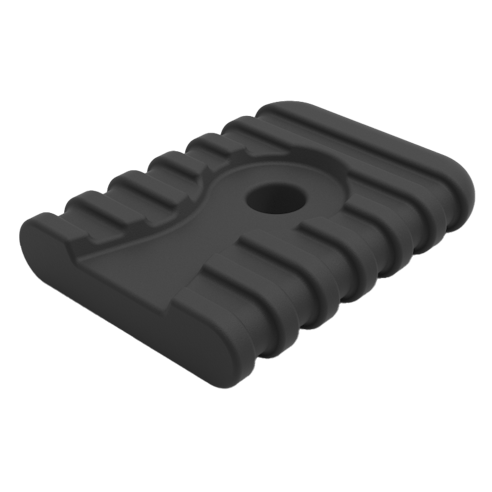

Consumer Products

Compression molding is often chosen for consumer goods that require custom shapes, soft-touch surfaces, or flexible features, like grips, pads, or buttons. EPDM is suitable for consumer products for its durability, weather resistance, and comfort.

Food and Beverage

This industry demands materials that meet strict regulatory standards while performing reliably under temperature and pressure changes. Food-grade silicone is the top choice for gaskets, seals, and components in processing equipment due to its non-reactive nature and ability to withstand repeated sanitization. Compression molding offers the precision and surface integrity required for food-safe parts without post-processing.

Manufacturing

In industrial and manufacturing environments, compression molding creates durable parts such as seals, vibration dampers, and protective covers. Materials like NBR, HNBR, and FKM (Viton®) are selected for their resistance to oils, chemicals, and extreme temperatures. The ability to mold thick or irregular shapes with consistent performance makes this process ideal for high-stress operational components.

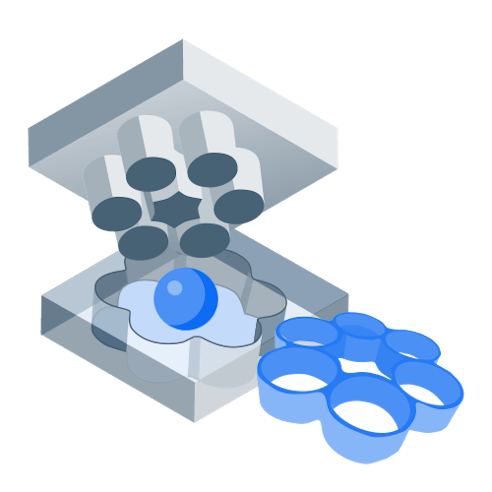

What is Compression Molding?

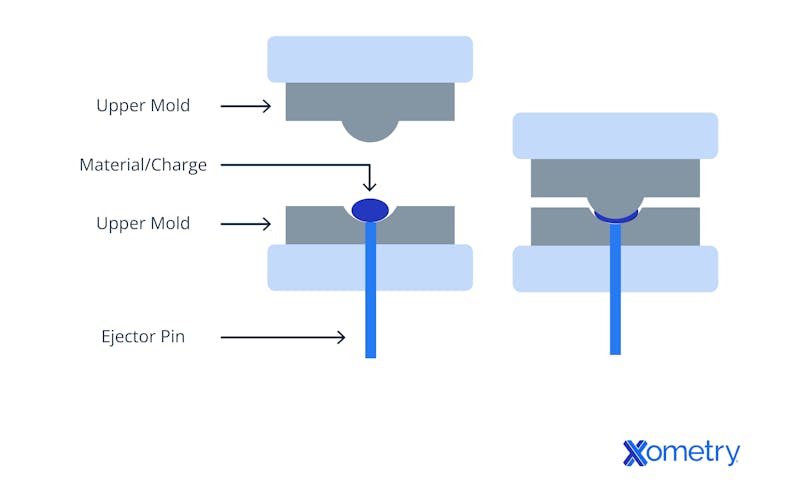

Compression molding, also known as pressure molding or press molding, is a manufacturing process used to shape materials such as thermosetting plastics, rubbers, or composite fibers by applying heat and pressure. The process begins with a pre-measured shot of material placed into a heated mold cavity. The mold is then closed, and the material is pressed with high pressure to force it to flow and fill the shape of the mold. Heat and pressure are held until the material cures. Once cured, the mold opens, and the formed part is ejected.

This technique is commonly used to produce strong, durable parts with complex shapes, making it popular in automotive, aerospace, and appliance industries. Compression molding is valued for its cost-effectiveness in medium to high-volume production, low material waste, and ability to create components with varied wall thicknesses that exhibit excellent mechanical performance.

Compression Molding Processes and Design

Compression molding design is a critical factor in the success of the process. Mold geometry, material flow paths, venting, and parting lines must be carefully engineered to accommodate the behavior of the chosen material under heat and pressure. Proper design minimizes defects such as voids, incomplete fills, or warping. Additionally, the design of the charge shape and placement, as well as the mold’s ability to withstand high loads, directly influences cycle times, scrap rates, and overall product performance. A well-designed compression mold not only improves quality but also extends tool life and reduces production costs.

Understanding the complete compression molding process from raw material handling to final part ejection can help achieve high-quality, cost-effective results. Below is a step-by-step breakdown of how the process works:

1. Material Preparation

A pre-measured amount of molding material, known as a "charge," is prepared. Depending on the application and material type (typically thermosets or composites), the material charge can take the form of pellets, putty, sheets, or preforms.

2. Mold Preheating

The compression mold is heated to a specific temperature, usually between 250°F and 400°F, to prepare for curing the material.

3. Material Loading

The prepared charge is placed directly into the open, heated mold cavity. Placement must be precise to ensure even distribution and minimize waste or defects.

4. Mold Closing and Pressing

The mold is closed using a compression molding press consisting of an upper and lower platen, where the mold halves are mounted. Depending on the part size and material, significant pressure is applied, typically ranging from 100 to 2,000 tons. The pressure forces the material to flow and fill the mold cavity completely.

5. Curing

While under pressure, the material is held at a high temperature for a set period to cure and harden through a chemical crosslinking process. This reaction ensures the molded component retains its final shape and structural integrity.

6. Mold Opening and Part Removal

Once curing is complete, the press opens, and the finished part is removed from the mold. Any excess material, known as flash, is trimmed, and the part may undergo secondary finishing if required.

Xometry Alternatives to Compression Molding

Custom Plastic Injection Molding Service

Liquid Silicone Rubber Molding

Custom Plastic Extrusion Services

Why Choose Xometry for Compression Molding?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get started with our easy-to-use platform and let our experts take care of managing the project from locating the right manufacturing partner to delivery logistics.

Vetted Network

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

Frequently Asked Questions About Compression Molding Services

What information do I need to provide to get an accurate quote?

To get started with a compression molding quote, simply upload your 3D CAD file and any supporting drawings to the Xometry Instant Quoting Engine®. Tooled processes, such as compression molding, require the CAD to be supplied in a native solid file format, such as STEP, SLDPRT, IPT, PRT, etc.

What materials can you work with for compression molding?

Xometry specializes in compression molding rubber elastomers such as silicone, NBR, FKM (Viton), EPDM, HNBR, IIR (Butyl), CR (Chloroprene), FVMQ, and FFKM.

What is your typical lead time for tooling and production?

The lead time for compression-molded orders is typically between 20 and 30 business days. However, this can vary depending on quantity, part complexity, and other project specifications.

Can you support both prototyping and high-volume production?

Yes! Xometry supports everything from smaller prototype runs to high-volume production. Additionally, we offer complementary services such as 3D printing and injection molding.

What tolerances can you achieve with compression molding?

Our standard tolerance for compression-molded parts is +/- 0.010". Tighter tolerances are achievable depending on geometry and material selection.

Do you provide design support or manufacturability feedback?

Yes! Xometry offers in-depth DFM reviews with every tooled process order to ensure successful outcomes. Our engineers and manufacturing experts will work closely with you every step of the way.

Can I supply my own tooling?

We typically do not accept customer-supplied compression molding tools to ensure the highest quality and avoid production issues. Tools not built to our specifications can lead to compatibility problems, inconsistent part quality, or equipment damage. Using in-house or approved tooling, we maintain complete control over the process, reduce risk, and deliver reliable, consistent results. That said, we’re happy to evaluate customer-supplied tooling on a case-by-case basis to determine feasibility and fit with our equipment and processes.

What quality control processes do you offer?

Xometry offers multiple options for quality control and part inspections. From standard inspections to first article inspections with reports to custom requests, we can accommodate your quality assurance needs. Read our article about our inspection options to learn more.

Do you support ITAR or ISO-certified projects?

Xometry is proud to be ITAR-registered, ISO 9001:2015, ISO 13485:2016, IATF 16949:2016, AS9100D, and CMMC Level 2 certified. As you build your quote, you can specify certification and qualification requirements by selecting from the corresponding options.