Metal Laser Cutting Services

High-quality metal laser cut parts in days | Free standard shipping on U.S. and international orders | International prototype pricing includes tariffs

Metal Laser Cutting by Xometry

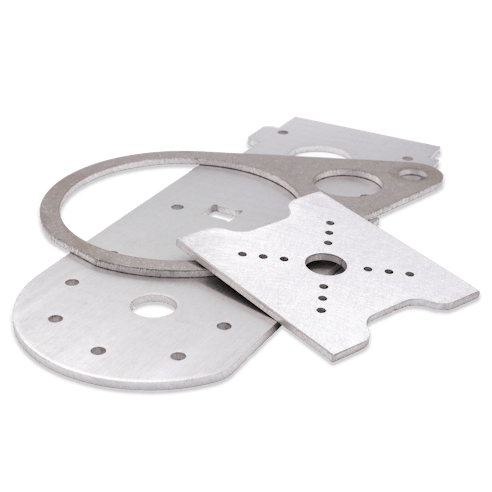

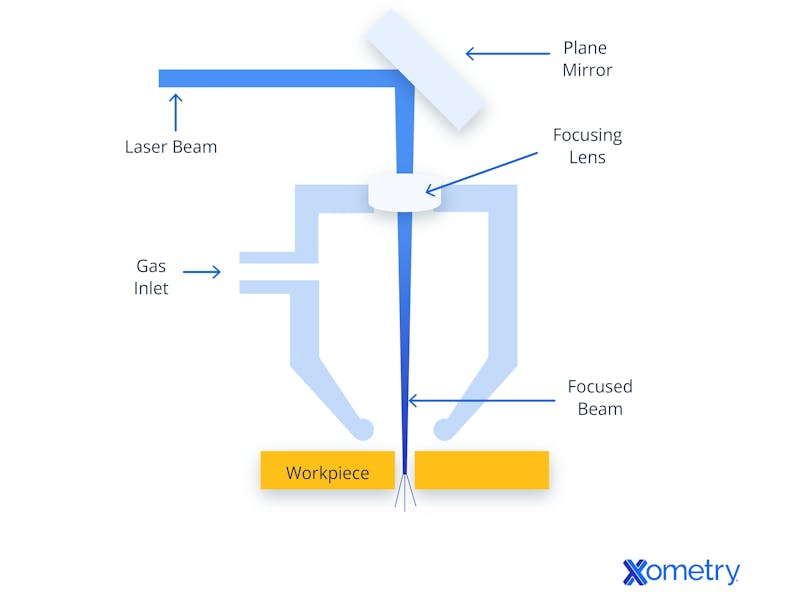

Xometry's metal laser cutting process is a high-precision manufacturing method that uses a focused laser beam to cut through sheets of metal material. Unlike mechanical cutting methods such as sawing or milling, laser cutting relies on concentrated light energy to melt or vaporize metal along a defined path. Compared to our other sheet cutting offerings, such as waterjet or plasma cutting, laser cutting offers unmatched accuracy, a minimal heat-affected zone, and exceptional repeatability, making it ideal for intricate shapes and tight tolerances.

Xometry's facilities utilize state-of-the-art equipment, including CO₂ and fiber lasers. These lasers are powerful, versatile, and effective for a range of metals, including aluminum and copper. This combination of precision, speed, and flexibility allows us to deliver clean, consistent results for everything from prototypes to higher volume production runs.

Upload your CAD files to the Xometry Instant Quoting Engine® to get an instant quote. What you see is what you pay. Your price for prototypes includes tariffs and shipping for standard parcels.

Xometry's Metal Laser Cutting Capabilities

| Capability | Description |

|---|---|

Capability Blank Sizes | Description Xometry has access to 10’ x 20’ platforms for laser cutting. However, many sheet stock sizes commonly cap out at 48” x 96” (4’ x 8’) or smaller. |

Capability Lead Times | Description Starting at 3 Days |

Capability Sheet Thickness | Description 0.020" up to beyond 1.00" depending on materials. Thinner or thicker stock may be possible through manual review. |

Capability Tight Tolerances | Description We can automatically quote sheet cutting tolerances as tight as +/- 0.005". Tolerances tighter than this are available after manual review. |

Capability General Tolerances | Description For full details on Xometry's general tolerances and standards for our sheet cutting service, please consult our manufacturing standards. |

Metal Laser Cutting Materials

| Material | Grades & Alloys | Common Thicknesses |

|---|---|---|

Material Aluminum | Grades & Alloys 2024-T3, 5052-H32, 6061-T6, 7075-T6, MIC-6 | Common Thicknesses 0.025”, 0.050”, 0.063”, 0.100”, 0.125", 0.250”, 0.375”, 0.500”, 0.750", 1.000" |

Material Brass | Grades & Alloys 260, 353-H02, 464-H01 | Common Thicknesses 0.032", 0.063", 0.080", 0.125", 0.250" |

Material Bronze | Grades & Alloys 220-H02, 510-H08 (spring), Bearing Bronze 932-M07, Silicon Bronze 655 | Common Thicknesses 0.020”, 0.032”, 0.040”, 0.050”, 0.063”, 0.080”, 0.090”, 0.125” |

Material Copper | Grades & Alloys 101 (H00 to H01), 110 (Annealed), 110-H01, 110-H02 | Common Thicknesses 0.025", 0.050", 0.063", 0.093", 0.125", 0.188", 0.250" |

Material Nickel | Grades & Alloys 200 (Annealed), 625 (Annealed) | Common Thicknesses 0.020”, 0.032”, 0.040”, 0.050”, 0.063” |

Material Stainless Steel | Grades & Alloys 17-4 PH, 17-7 shim, 301 (spring), 304, 316, 410, 430, 440C,CPM 154, CPM S30V | Common Thicknesses 0.018", 0.024", 0.048", 0.060", 0.094", 0.120", 0.125", 0.188", 0.250", 0.375", 0.500", 0.750", 1.000" |

Material Spring Steel | Grades & Alloys 1075 (Annealed), 1075 (Blue Temper), 1095 (Annealed), 1095 (Blue Temper) | Common Thicknesses 0.015”, 0.050”, 0.063”, 0.125”, 0.188” |

Material Carbon Steel | Grades & Alloys 1045, 1008, 1018, A36, A366/1008, A572 Grade 50, G90 (galvanized) | Common Thicknesses 0.060”, 0.075”, 0.100”, 0.125”, 0.188”, 0.250”, 0.375”, 0.500” |

Material Tool Steel | Grades & Alloys Tool Steel D2, Tool Steel O1 | Common Thicknesses 0.063”, 0.094”, 0.125”, 0.156”, 0.188” |

Material Other Alloy Steels | Grades & Alloys 4130, 4140, 80CRV2, AR400, AR500, Corten A588, A569/ASTM A1011 | Common Thicknesses 0.063", 0.090", 0.125", 0.188", 0.250", 0.375", 0.500", 0.750", 1.000" |

Material Titanium | Grades & Alloys Grade 2, 6Al-4V (Grade 5) | Common Thicknesses 0.032”, 0.063”, 0.125”, 0.188”, 0.250” |

For a complete list of our sheet materials and thicknesses, visit our Standard Sheet Sizes page.

Metal Laser Cutting Advantages

Metal laser cutting combines precision, efficiency, and versatility to move projects from concept to finished parts confidently. It's a reliable process that delivers consistent results at every stage. Key advantages include:

- Precision and Accuracy

- Speed and Efficiency

- Minimal Post-Processing

- Cost-Effectiveness

Precision and Accuracy

Laser cutting delivers exact cuts with tight tolerances, allowing for intricate designs and complex geometries that would be difficult or impossible with mechanical methods. This precision reduces the risk of assembly issues and ensures parts meet exact specifications.

Speed and Efficiency

Laser cutting is significantly faster than traditional methods for many applications, especially for thin to medium-thickness sheets. Rapid cutting cycles and automated CNC control enable high throughput and shorter lead times, making it ideal for prototyping and production runs.

Minimal Post-Processing

The focused laser beam produces clean edges with little distortion, reducing the need for secondary finishing operations such as grinding, deburring, or sanding. This not only saves time but also preserves part integrity and surface quality.

Cost-Effectiveness

Laser cutting often lowers production costs by combining high precision, automation, and minimal material waste. Optimized nesting reduces scrap, faster cycle times reduce labor costs, and minimal post-processing lowers downstream expenses.

Metal Laser Cutting Industries and Applications

Metal laser cutting is a versatile process trusted across a wide range of industries. It delivers precise, repeatable results in various metals, making it well-suited for applications from specialized and custom components to high-volume production. Xometry provides metal laser cutting for customers from industries such as:

- Automotive

- Medical

- Aerospace

- Industrial

- Architecture

Automotive

Laser cutting supports both prototyping and production of parts where accuracy and repeatability are critical. It is widely used for brackets, exhaust components, and custom body panels. The speed of the process supports high-volume output and has the versatility to cut materials such as aluminum for lightweighting and stainless steel for durability.

Medical

The medical industry requires parts with exceptional precision and consistency, often from materials that can withstand sterilization and resist corrosion. Laser cutting is well-suited for stainless steels, titanium, and certain aluminum alloys used in surgical instruments, implant components, and device enclosures. The process produces clean, burr-free edges and fine geometries while maintaining the material integrity needed for critical healthcare applications.

Aerospace

Aerospace manufacturing depends on lightweight, high-strength metals cut to exact tolerances. Laser cutting is commonly applied to aluminum and titanium parts such as brackets, housings, and airframe reinforcements, supporting rapid prototyping and consistent production of certified components.

Industrial

In industrial equipment and machinery, laser cutting delivers fast turnaround on machine guards, control panels, brackets, and enclosures. The process handles a wide range of metals and thicknesses, ensuring consistent quality and quick production of new and replacement components.

Architecture

Architectural and construction applications benefit from laser cutting’s ability to create custom patterns and fine details in metals such as steel, aluminum, and brass. Decorative panels, signage, railings, and structural features can all be fabricated efficiently with high design flexibility.

How Metal Laser Cutting Works

Our metal laser cutting process begins with your submitted CAD files, which define the part's geometry. These files are processed through CAM (computer-aided manufacturing) software, which generates the cutting paths, assigns parameters for the material and thickness, and integrates component nesting to maximize material use and minimize scrap.

The finalized program is sent to a CNC-controlled laser cutting machine. Metal sheets are manually loaded onto the cutting table or through automated material handling equipment. The program is executed on the machine, and its precisely focused laser beam follows the designated paths to accurately cut the part profile from the material.

After cutting, parts are removed from the sheet, and a quality control check is performed to confirm part dimensions. Based on your Xometry order specifications, the parts undergo additional post-processing, which can include edge and surface cleanup and secondary finishes, such as powder coating. Final inspection is the last step, consisting of visual checks, dimensional verification, and documentation, before packing and shipping.

Design Guidelines for Metal Laser Cutting

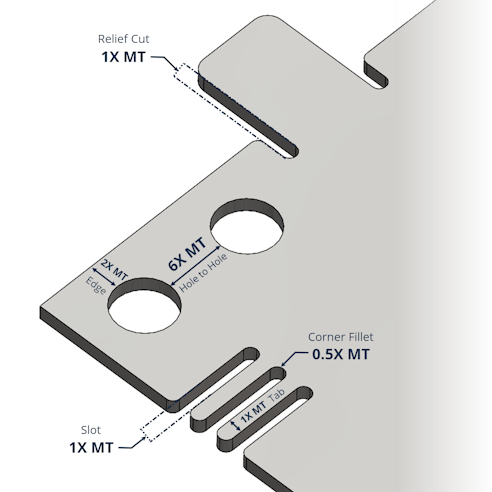

Thoughtful design is essential to getting the best results from metal laser cutting. Feature spacing, hole and detail sizes, and kerf all influence cut quality and overall manufacturability. By following proven design guidelines, engineers and designers can optimize parts for precision, efficiency, and cost-effectiveness while minimizing post-processing needs.

Distance Between Features

A minimum distance between features should be maintained to ensure the integrity of the cut.

Following the guidelines below will ensure reliable results with the laser cutting method.

• Minimum Hole to Edge Distance = 2X MT or 0.125”, whichever is smaller

• Minimum Hole to Hole Distance = 6X MT or 0.125”, whichever is smaller

• Minimum Relief Cuts = 0.010” or 1X MT, whichever is greater

• Minimum Corner Fillets = 0.5X MT or 0.125”, whichever is smaller

• Minimum Tab Thickness = 0.063” or 1X MT, whichever is greater

• Minimum Slot Thickness = 0.040” or 1X MT, whichever is greater

Kerf

Kerf refers to the material that is burnt or cut away by the cutting tool, whether that be a laser, waterjet, or saw blade. Kerf is the gap thickness that the cutting tool creates and varies depending on the process and material thickness. For metal laser cutting, the typical kerf width is between 0.008" and 0.012". Keep the kerf in mind when designing your part, as small holes, thin gaps, and relief cuts may be slightly larger than dimensioned if their design is close to the kerf thickness. When designing mating parts, you should compensate for the kerf by adding half the kerf width to the inner part and subtracting half the kerf width from the outer part.

Minimum Feature Size

Before a feature is cut, the laser beam must pierce through the material at the start point of the cut. Holes and other internal shapes should be sized appropriately for this action.

A good rule of thumb is to design your details at least 50% of the material’s thickness or larger. Also, remember to account for kerf width, as features designed below the kerf width will be blown out or lost.

Looking for more sheet cutting design tips?

Alternatives to Metal Laser Cutting

Online Waterjet Cutting Service

Metal Stamping Services

Custom Online CNC Machining Services

Why Choose Xometry for Laser Cutting?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get started with our easy-to-use platform and let our experts take care of managing the project from locating the right manufacturing partner to delivery logistics.

Vetted Network

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.

Frequently Asked Questions About Metal Laser Cutting

What information do I need to provide to get an accurate quote?

To get a metal laser cutting quote, upload your CAD file and supporting drawings to the Xometry Instant Quoting Engine®. We support 3D CAD formats such as STEP, SLDPRT, PRT, IPT, and more, as well as 2D DXF files. Set the process to "Sheet Cutting" and fully configure your parts, ensuring features like tight tolerances, inserts, and part markings are specified.

What tolerances can you achieve with laser cutting?

Our standard edge-to-edge tolerance for metal laser-cut parts is ±.010” nominal on the top face of the plate/sheet. Auto-quoting is available for tolerances as tight as ±0.005" for most materials, with tighter tolerances available after manual review. Thickness tolerances are independent of cutting tolerances, as they rely on the raw stock material’s tolerance range.

What is your max cutting thickness?

We can generally achieve a maximum cutting depth of up to 1.000" on metal materials. This may vary depending on the type of metal, as some are more reflective or conductive than others, which can influence the laser's cutting ability.

What is your typical lead time?

The lead time for metal laser cutting orders starts at three business days and increases from there depending on project-specific requirements such as quantity, part complexity, and other specifications.

Do you offer secondary processes?

Yes! Xometry can automatically quote different secondary finishes for your metal laser cut parts, including anodization, powder coating, chem-film, passivation, metal plating, and more. Visit our metal finishes gallery for examples.

Do you offer certifications or inspections?

Xometry offers multiple options for quality control and part inspections. From standard inspections to first article inspections with reports to custom requests, we can accommodate your quality assurance needs. Read our article about our inspection options to learn more.

What if my part needs both cutting and bending?

Xometry has you covered! In addition to laser cutting, we also offer sheet metal bending and assembly services. We can fabricate custom bent parts requiring weldments, inserts, and more. Learn more by visiting our sheet metal fabrication page.